#287: Robonomics Platform: Integrating Robots into the Economy, with Aleksandr Kapitonov

In this episode, Lilly Clark interviews Aleksandr Kapitonov, “robot economics” academic society professor at Airalab, on his work for Robonomics Platform, an Ethereum network infrastructure for integrating robots and cyber-physical systems directly into the economy. Kapitonov discusses the advantages of using blockchain, use cases including a fully autonomous vending machine, and the Robonomics technology stack.

Below are two videos showing the Robonomics Platform in action via a fully autonomous robot artist and drones for environmental monitoring.

Aleksandr Kapitonov

Aleksandr Kapitonov is a “robot economics” academic society progressor at Airalab (the team behind Robonomics Platform), an assistant professor of Control Systems and Robotics at ITMO University, and regional coordinator of the Erasmus+ IOT-OPEN.EU project for researching and developing IoT education practices. His research focuses on navigation, computer vision, control of mobile robots and communication for multi-agents systems.

Aleksandr Kapitonov is a “robot economics” academic society progressor at Airalab (the team behind Robonomics Platform), an assistant professor of Control Systems and Robotics at ITMO University, and regional coordinator of the Erasmus+ IOT-OPEN.EU project for researching and developing IoT education practices. His research focuses on navigation, computer vision, control of mobile robots and communication for multi-agents systems.

Links

Army project develops agile scouting robots

Compact Mechatronic Drive for Robotic Applications

Drones for inspecting Roofs for Home Insurance Are Becoming the Norm

Model-based reinforcement learning from pixels with structured latent variable models

By Marvin Zhang and Sharad Vikram

By Marvin Zhang and Sharad Vikram

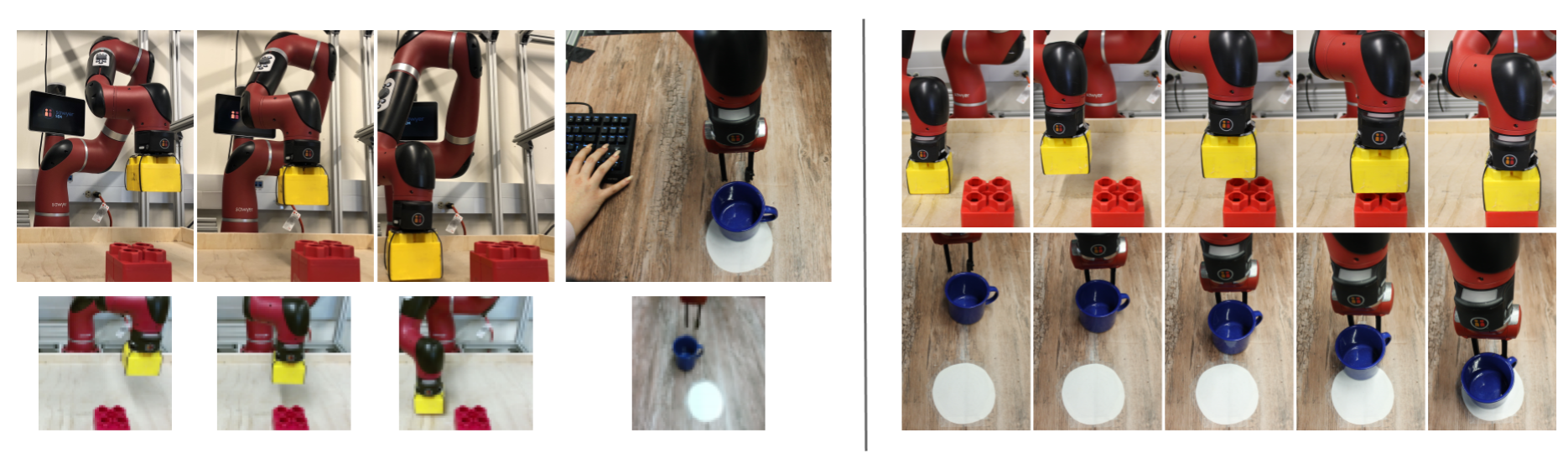

Imagine a robot trying to learn how to stack blocks and push objects using visual inputs from a camera feed. In order to minimize cost and safety concerns, we want our robot to learn these skills with minimal interaction time, but efficient learning from complex sensory inputs such as images is difficult. This work introduces SOLAR, a new model-based reinforcement learning (RL) method that can learn skills – including manipulation tasks on a real Sawyer robot arm – directly from visual inputs with under an hour of interaction. To our knowledge, SOLAR is the most efficient RL method for solving real world image-based robotics tasks.

Our robot learns to stack a Lego block and push a mug onto a coaster with only inputs from a camera pointed at the robot. Each task takes an hour or less of interaction to learn.

In the RL setting, an agent such as our robot learns from its own experience through trial and error, in order to minimize a cost function corresponding to the task at hand. Many challenging tasks have been solved in recent years by RL methods, but most of these success stories come from model-free RL methods, which typically require substantially more data than model-based methods. However, model-based methods often rely on the ability to accurately predict into the future in order to plan the agent’s actions. This is an issue for image-based learning as predicting future images itself requires large amounts of interaction, which we wish to avoid.

There are some model-based RL methods that do not require accurate future prediction, but these methods typically place stringent assumptions on the state. The LQR-FLM method has been shown to learn new tasks very efficiently, including for real robotic systems, by modeling the dynamics of the state as approximately linear. This assumption, however, is prohibitive for image-based learning, as the dynamics of pixels in a camera feed are far from linear. The question we study in our work is: how can we relax this assumption in order to develop a model-based RL method that can solve image-based tasks without requiring accurate future predictions?

We tackle this problem by learning a latent state representation using deep neural networks. When our agent is faced with images from the task, it can encode the images into their latent representations, which can then be used as the state inputs to LQR-FLM rather than the images themselves. The key insight in SOLAR is that, in addition to learning a compact latent state that accurately captures the objects, we specifically learn a representation that works well with LQR-FLM by encouraging the latent dynamics to be linear. To that end, we introduce a latent variable model that explicitly represents latent linear dynamics, and this model combined with LQR-FLM provides the basis for the SOLAR algorithm.

Stochastic Optimal Control with Latent Representations

SOLAR stands for stochastic optimal control with latent representations, and it is an efficient and general solution for image-based RL settings. The key ideas behind SOLAR are learning latent state representations where linear dynamics are accurate, as well as utilizing a model-based RL method that does not rely on future prediction, which we describe next.

Linear Dynamical Control

Using the system state, LQR-FLM and related methods have been used to successfully learn a myriad of tasks including robotic manipulation and locomotion. We aim to extend these capabilities by automatically learning the state input to LQR-FLM from images.

One of the best-known results in control theory is the linear-quadratic regulator (LQR), a set of equations that provides the optimal control strategy for a system in which the dynamics are linear and the cost is quadratic. Though real world systems are almost never linear, approximations to LQR such as LQR with fitted linear models (LQR-FLM) have been shown to perform well at a variety of robotic control tasks. LQR-FLM has been one of the most efficient RL methods at learning control skills, even compared to other model-based RL methods. This efficiency is enabled by the simplicity of linear models as well as the fact that these models do not need to predict accurately into the future. This makes LQR-FLM an appealing method to build from, however the key limitation of this method is that it normally assumes access to the system state, e.g., the joint configuration of the robot and the positions of objects of interest, which can often be reasonably modeled as approximately linear. We instead work from images and relax this assumption by learning a representation that we can use as the input to LQR-FLM.

Learning Latent States from Images

The graphical model we set up presumes that the images we observe are a function of a latent state, and the states evolve according to linear dynamics modulated by actions, and where the costs are given by a quadratic function of the state and action.

We want our agent to extract, from its visual input, a state representation where the dynamics of the state are as close to linear as possible. To accomplish this, we devise a latent variable model in which the latent states obey linear dynamics, as detailed in the graphic above. The dark nodes are what we observe from interacting with the environment – namely, images, actions taken by the agent, and costs. The light nodes are the underlying states, which is the representation that we wish to learn, and we posit that the next state is a linear function of the current state and action. This model bears strong resemblance to the structured variational auto-encoder (SVAE), a model previously applied to applications such as characterizing videos of mice. The method that we use to fit our model is also based off of the method presented in this prior work.

At a high level, our method learns both the state dynamics and an encoder, which is a function that takes as input the current and past images and outputs a guess of the current state. If we encode many observation sequences corresponding to the agent’s interactions with the environment, we can see if these state sequences behave according to our learned linear dynamics – if they don’t, we adjust our dynamics and our encoder to bring them closer in line. One key aspect of this procedure is that we do not directly optimize our model to be accurate at predicting into the future, since we only fit linear models retrospectively to the agent’s previous interactions. This strongly complements LQR-FLM which, again, does not rely on prediction for good performance. Our paper provides more details about our model learning procedure.

The SOLAR Algorithm

Our robot iteratively interacts with its environment, uses this data to update its model, uses this model to estimate the latent states and their dynamics, and uses these dynamics to update its behavior.

Now that we have described the building blocks of our method, how do these pieces fit together into the SOLAR method? The agent acts in the environment according to its policy, which prescribes actions based on the current latent state estimate. These interactions produce trajectories of images, actions, and costs that are then used to fit the model detailed in the previous section. Afterwards, using these entire trajectories of interactions, our model retrospectively refines its estimate of the latent dynamics, which allows LQR-FLM to produce an updated policy that should perform better at the given task, i.e., incur lower costs. The updated policy is then used to collect more trajectories, and the procedure repeats. The graphic above depicts these stages of the algorithm.

The key difference between LQR-FLM and most other model-based RL methods is that the resulting models are only used for policy improvement and not for prediction into the future. This is useful in settings where the observations are complex and difficult to predict, and we extend this benefit into image-based settings by introducing latent states that we can estimate alongside the dynamics. As seen in the next section, SOLAR can produce good policies for image-based robotic manipulation tasks using only one hour of interaction time with the environment.

Experiments

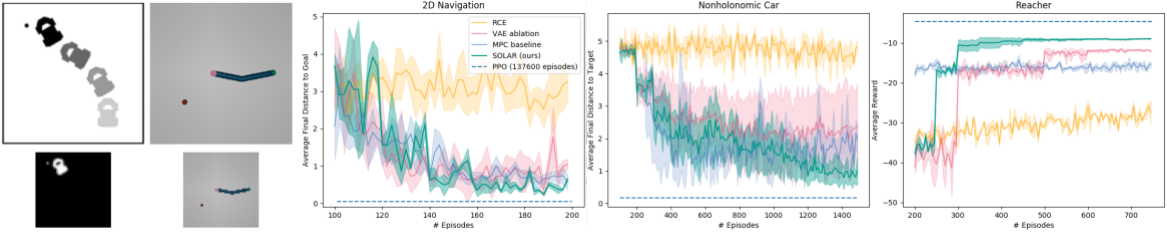

Left: For Lego block stacking, we experiment with multiple starting positions of the arm and block. For pushing, we only use sparse rewards provided by a human pushing a key when the robot succeeds. Example image observations are given in the bottom row. Right: Examples of successful behaviors learned by SOLAR.

Our main testbed for SOLAR is the Sawyer robotic arm, which has seven degrees of freedom and can be used for a variety of manipulation tasks. We feed the robot images from a camera pointed at its arm and the relevant objects in the scene, and we task our robot with learning Lego block stacking and mug pushing, as detailed below.

Lego Block Stacking

https://youtube.com/watch?v=X5RjE–TUGs%3Frel%3D0

Using SOLAR, our Sawyer robot efficiently learns stacking from only image observations from all three initial positions. The ablations are less successful, and DVF does not learn as quickly as SOLAR. In particular, these methods have difficulty with the challenging setting where the block starts on the table.

The main challenge for block stacking stems from the precision required to succeed, as the robot must very accurately place the block in order to properly connect the pieces. Using SOLAR, the Sawyer learns this precision from only the camera feed, and moreover the robot can successfully learn to stack from a number of starting configurations of the arm and block. In particular, the configuration where the block starts on the table is the most challenging, as the Sawyer must learn to first lift the block off the table before stacking it – in other words, it can’t be “greedy” and simply move toward the other block.

We first compare SOLAR to an ablation that uses a standard variational auto-encoder (VAE) rather than the SVAE, which means that the state representation is not learned to follow linear dynamics. This ablation is only successful on the easiest starting configuration. In order to understand what benefits we extract from not requiring accurate future predictions, we compare to another ablation which replaces LQR-FLM with an alternative planning method known as model-predictive control (MPC), and we also compare to a state-of-the-art prior method that uses MPC, deep visual foresight (DVF). MPC has been used in a number of prior and subsequent works, and it relies on being able to generate accurate future predictions using the learned model in order to determine what actions are likely to lead to good performance.

The MPC ablation learns more quickly on the two easier configurations, however, it fails in the most difficult setting because MPC greedily reduces the distance between the two blocks rather than lifting the block off the table. MPC acts greedily because it only plans over a short horizon, as predicting future images becomes increasingly inaccurate over longer horizons, and this is exactly the failure mode that SOLAR is able to overcome by utilizing LQR-FLM to avoid future predictions altogether. Finally, we find that DVF can make progress but ultimately is not able to solve the two harder settings even with more data than what we use for our method. This highlights our method’s data efficiency, as we use in total a few hours of robot data compared to days or weeks of data as in DVF.

Mug Pushing

https://youtube.com/watch?v=buk4YE2mFTs%3Frel%3D0

Despite the challenge of only having sparse rewards provided by a human key press, our robot running SOLAR learns to push the mug onto the coaster in under an hour. DVF is again not as efficient and does not learn as quickly as SOLAR.

We add an additional challenge to mug pushing by replacing the costs with a sparse reward signal, i.e., the robot only gets told when it has completed the task, and it is told nothing otherwise. As seen in the picture above, the human presses a key on the keyboard in order to provide the sparse reward, and the robot must reason about how improve its behavior in order to achieve this reward. This is implemented via a straightforward extension to SOLAR, as we detail in the paper. Despite this additional challenge, our method learns a successful policy in about an hour of interaction time, whereas DVF performs worse than our method using a comparable amount of data.

Simulated Comparisons

Left: an illustration of the car and reacher environments we experiment with, along with example image observations in the bottom row. Right: our method generally performs better than the ablations we compare to, as well as RCE. PPO has better final performance, however PPO requires one to three orders of magnitude more data than SOLAR to reach this performance.

In addition to the Sawyer experiments, we also run several comparisons in simulation, as most prior work does not experiment with real robots. In particular, we set up a 2D navigation domain where the underlying system actually has linear dynamics and quadratic cost, but we can only observe images that show a top-down view of the agent and the goal. We also include two domains that are more complex: a car that must drive from the bottom right to the top left of a 2D plane, and a 2 degree of freedom arm that is tasked with reaching to a goal in the bottom left. All domains are learned with only image observations that provide a top down view of the task.

We compare to robust locally-linear controllable embeddings (RCE), which takes a different approach to learning latent state representations that follow linear dynamics. We also compare to proximal policy optimization (PPO), a model-free RL method that has been used to solve a number of simulated robotics domains but is not data efficient enough for real world learning. We find that SOLAR learns faster and achieves better final performance than RCE. PPO typically learns better final performance than SOLAR, but this typically requires one to three orders of magnitude more data, which again is prohibitive for most real world learning tasks. This kind of tradeoff is typical: model-free methods tend to achieve better final performance, but model-based methods learn much faster. Videos of the experiments can be viewed on our project website.

Related Work

Approaches to learning latent representations of images have proposed objectives such as reconstructing the image and predicting future images. These objectives do not line up perfectly with our objective of accomplishing tasks – for example, a robot tasked with sorting objects into bins by color does not need to perfectly reconstruct the color of the wall in front of it. There has also been work on learning state representations that are suitable for control, including identifying points of interest within the image and learning latent states such that dimensions are independently controllable. A recent survey paper categorizes the landscape of state representation learning.

Separately from control, there has been a number of recent works that learn structured representations of data, many of which extend VAEs. The SVAE is an example of one such framework, and some other methods also attempt to explain the data with linear dynamics. Beyond this, there have been works that learn latent representations with mixture model structure, various discrete structures, and Bayesian nonparametric structures.

Ideas that are closely related to ours have been proposed in prior and subsequent work. As mentioned before, DVF has also learned robotics tasks directly from vision, and a recent blog post summarizes their results. Embed to control and its successor RCE also aim to learn latent state representations with linear dynamics. We compare to these methods in our paper and demonstrate that our method tends to exhibit better performance. Subsequent to our work, PlaNet learns latent state representations with a mixture of deterministic and stochastic variables and uses them in conjunction with MPC, one of the baseline methods in our evaluation, demonstrating good results on several simulated tasks. As shown by our experiments, LQR-FLM and MPC each have their respective strengths and weaknesses, and we found that LQR-FLM was typically more successful for robotic control, avoiding the greedy behavior of MPC.

Future Work

We see several exciting directions for future work, and we’ll briefly mention two. First, we want our robots to be able to learn complex, multi-stage tasks, such as building Lego structures rather than just stacking one block, or setting a table rather than just pushing one mug. One way we may realize this is by providing intermediate images of the goals we want the robot to accomplish, and if we expect that the robot can learn each stage separately, it may be able to string these policies together into more complex and interesting behaviors. Second, humans don’t just learn representations of states but also actions – we don’t think about individual muscle movements, we group such movements together into “macro-actions” to perform highly coordinated and sophisticated behaviors. If we can similarly learn action representations, we can enable our robots to more efficiently learn how to use hardware such as dexterous hands, which will further increase their ability to handle complex, real-world environments.

This post is based on the following paper:

- Marvin Zhang*, Sharad Vikram*, Laura Smith, Pieter Abbeel, Matthew J. Johnson, Sergey Levine.

SOLAR: Deep Structured Representations for Model-Based Reinforcement Learning.

International Conference on Machine Learning (ICML), 2019.

Project webpage

Open-source code

We would like to thank our co-authors, without whom this work would not be possible, for also contributing to and providing feedback on this post, in particular Sergey Levine. We would also like to thank the many people that have provided insightful discussions, helpful suggestions, and constructive reviews that have shaped this work. This article was initially published on the BAIR blog, and appears here with the authors’ permission.

Better together: Human and robot co-workers more efficient, less accident-prone

Bringing human-like reasoning to driverless car navigation

Image: Chelsea Turner

By Rob Matheson

With aims of bringing more human-like reasoning to autonomous vehicles, MIT researchers have created a system that uses only simple maps and visual data to enable driverless cars to navigate routes in new, complex environments.

Human drivers are exceptionally good at navigating roads they haven’t driven on before, using observation and simple tools. We simply match what we see around us to what we see on our GPS devices to determine where we are and where we need to go. Driverless cars, however, struggle with this basic reasoning. In every new area, the cars must first map and analyze all the new roads, which is very time consuming. The systems also rely on complex maps — usually generated by 3-D scans — which are computationally intensive to generate and process on the fly.

In a paper being presented at this week’s International Conference on Robotics and Automation, MIT researchers describe an autonomous control system that “learns” the steering patterns of human drivers as they navigate roads in a small area, using only data from video camera feeds and a simple GPS-like map. Then, the trained system can control a driverless car along a planned route in a brand-new area, by imitating the human driver.

Similarly to human drivers, the system also detects any mismatches between its map and features of the road. This helps the system determine if its position, sensors, or mapping are incorrect, in order to correct the car’s course.

To train the system initially, a human operator controlled an automated Toyota Prius — equipped with several cameras and a basic GPS navigation system — to collect data from local suburban streets including various road structures and obstacles. When deployed autonomously, the system successfully navigated the car along a preplanned path in a different forested area, designated for autonomous vehicle tests.

“With our system, you don’t need to train on every road beforehand,” says first author Alexander Amini, an MIT graduate student. “You can download a new map for the car to navigate through roads it has never seen before.”

“Our objective is to achieve autonomous navigation that is robust for driving in new environments,” adds co-author Daniela Rus, director of the Computer Science and Artificial Intelligence Laboratory (CSAIL) and the Andrew and Erna Viterbi Professor of Electrical Engineering and Computer Science. “For example, if we train an autonomous vehicle to drive in an urban setting such as the streets of Cambridge, the system should also be able to drive smoothly in the woods, even if that is an environment it has never seen before.”

Joining Rus and Amini on the paper are Guy Rosman, a researcher at the Toyota Research Institute, and Sertac Karaman, an associate professor of aeronautics and astronautics at MIT.

Point-to-point navigation

Traditional navigation systems process data from sensors through multiple modules customized for tasks such as localization, mapping, object detection, motion planning, and steering control. For years, Rus’s group has been developing “end-to-end” navigation systems, which process inputted sensory data and output steering commands, without a need for any specialized modules.

Until now, however, these models were strictly designed to safely follow the road, without any real destination in mind. In the new paper, the researchers advanced their end-to-end system to drive from goal to destination, in a previously unseen environment. To do so, the researchers trained their system to predict a full probability distribution over all possible steering commands at any given instant while driving.

The system uses a machine learning model called a convolutional neural network (CNN), commonly used for image recognition. During training, the system watches and learns how to steer from a human driver. The CNN correlates steering wheel rotations to road curvatures it observes through cameras and an inputted map. Eventually, it learns the most likely steering command for various driving situations, such as straight roads, four-way or T-shaped intersections, forks, and rotaries.

“Initially, at a T-shaped intersection, there are many different directions the car could turn,” Rus says. “The model starts by thinking about all those directions, but as it sees more and more data about what people do, it will see that some people turn left and some turn right, but nobody goes straight. Straight ahead is ruled out as a possible direction, and the model learns that, at T-shaped intersections, it can only move left or right.”

What does the map say?

In testing, the researchers input the system with a map with a randomly chosen route. When driving, the system extracts visual features from the camera, which enables it to predict road structures. For instance, it identifies a distant stop sign or line breaks on the side of the road as signs of an upcoming intersection. At each moment, it uses its predicted probability distribution of steering commands to choose the most likely one to follow its route.

Importantly, the researchers say, the system uses maps that are easy to store and process. Autonomous control systems typically use LIDAR scans to create massive, complex maps that take roughly 4,000 gigabytes (4 terabytes) of data to store just the city of San Francisco. For every new destination, the car must create new maps, which amounts to tons of data processing. Maps used by the researchers’ system, however, captures the entire world using just 40 gigabytes of data.

During autonomous driving, the system also continuously matches its visual data to the map data and notes any mismatches. Doing so helps the autonomous vehicle better determine where it is located on the road. And it ensures the car stays on the safest path if it’s being fed contradictory input information: If, say, the car is cruising on a straight road with no turns, and the GPS indicates the car must turn right, the car will know to keep driving straight or to stop.

“In the real world, sensors do fail,” Amini says. “We want to make sure that the system is robust to different failures of different sensors by building a system that can accept these noisy inputs and still navigate and localize itself correctly on the road.”

A.I. —Rules, Learning and Reason

How Robotics are Automating a Solution to the Labor Shortage & Growing Customer Demands

The Future of “Cobots” is AI Voice Interface at the Edge

Programming the forces of evolution

Winner of Fetch Robotics FetchIt! Challenge Executes Complex Manufacturing Tasks Using Autonomous Mobile Robotic Arm

How to explore inaccessible places by swarms of sensors

Live coverage of #ICRA2019

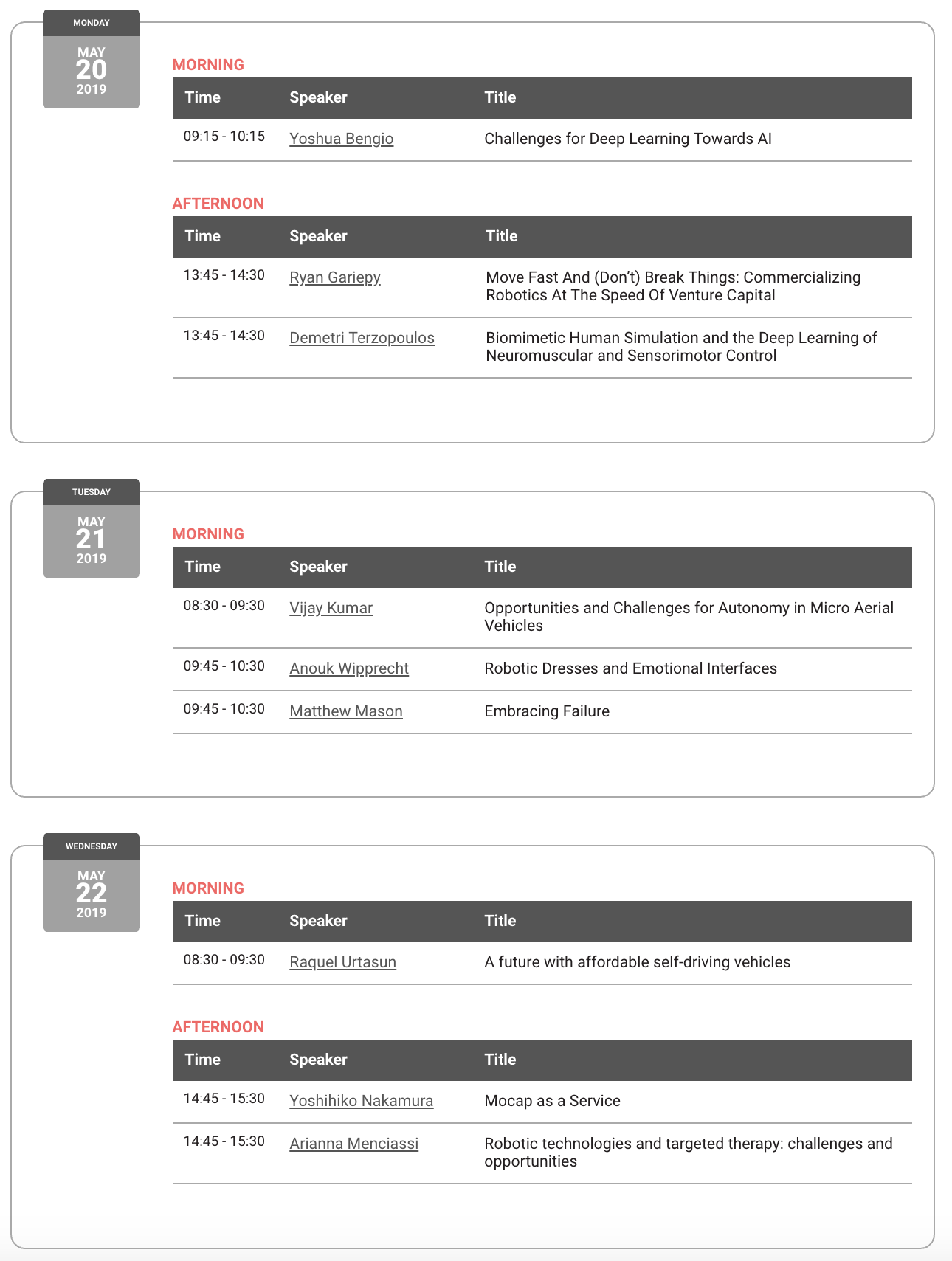

The IEEE International Conference on Robotics and Automation (ICRA) is being held this week in Montreal, Canada. It’s one of the top venues for roboticists and attracts over 4000 conference goers.

The IEEE International Conference on Robotics and Automation (ICRA) is being held this week in Montreal, Canada. It’s one of the top venues for roboticists and attracts over 4000 conference goers.

Andra, Audrow, Lauren, and Lilly are on the ground so expect lots of great podcasts, videos with best-paper nominees, and coverage in the weeks and months ahead.

For a taste of who is presenting, here is the schedule of keynotes.

It also looks like you can navigate the program, read abstracts, and watch spotlight presentations by following these instructions.

Finally, check latest tweets at #ICRA2019.