Smart robot can lend hospitals a big hand

Nimble robotic arms that perform delicate surgery may be one step closer to reality

What Technologies Is Amazon Developing to Keep Workers Safe?

Google parent launches new ‘moonshot’ for robotics software

Better behaving bots: Researcher helps robots problem solve and care

RO-MAN 2021 Roboethics Competition: Bringing ethical robots into the home

In 1984, Heathkit presented HERO Jr. as the first robot that could be used in households to perform a variety of tasks, such as guarding people’s homes, setting reminders, and even playing games. Following this development, many companies launched affordable “smart robots” that could be used within the household. Some of these technologies, like Google Home, Amazon Echo and Roomba, have become household staples; meanwhile, other products such as Jibo, Aniki, and Kuri failed to successfully launch despite having all the necessary resources.

By Marshall Astor – flickr.com, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=5531066

Why were these robots shut down? Why aren’t there more social and service robots in households, particularly with the rising eldery population and increasing number of full-time working parents? The simple answer is that most of these personal robots do not work well—but this is not necessarily because we do not have the technological capacity to build highly functional robots.

Technologists have accomplished amazing physical tasks with robots such as a humanoid robot that can perform gymnastics movements or a robotic dog that traverses through rough trails. However, as of now we cannot guarantee that these robots/personal assistants act appropriately in the complex and sensitive social dynamics of a household. This poses a significant obstacle in developing domestic service robots because companies would be liable for any harms a socially inappropriate robot causes. As robots become more affordable and feasible technically, the challenge of designing robots that act in accordance with context-specific social norms becomes increasingly pronounced. Researchers in human-robot interaction and roboethics have attempted to resolve this issue for the past few decades, and while progress has been made, there is an urgent need to address the ethical implications of service robots in practice.

As an attempt to take a more solution-focused path for these challenges, we are happy to share a completely new competition with our readers. This year, the Roboethics to Design & Development competition will take place as a part of RO-MAN—an international conference on robot and human interactive communication. The competition, the first and only one of its kind, fulfills a need for interactive education on roboethics.

In partnership with RoboHub at the University of Waterloo, the competition organizers designed a virtual environment where participating teams will develop a robot that fetches objects in a home. The household is composed of a variety of personas—a single mother who works as a police officer, a teenage daughter, her college-aged boyfriend, a baby, and a dog. For example, design teams will need to consider how a home robot may respond to the daughter’s request to take her parent’s credit card. In this ethical conundrum, should the robot obey the daughter, and would the robot be responsible if the daughter were to use the credit card without her mom’s permission?

How can we identify and address ethical challenges presented by a home robot?

Participants are challenged to tackle the long-standing problem of how we can design a safe and ethical robot in a dynamic environment where values, beliefs, and priorities may be in conflict. With submissions from around the world, it will be fascinating to see how solutions may differ and translate across cultures.

It is important to recognize that there is a void when searching for standards and ethical rules in robotics. In an attempt to address this void, various toolkits have been developed to guide technologists in identifying and resolving ethical challenges. Here are some steps from the Foresight into AI Ethics Toolkit that will be helpful in designing an ethical home robot:

- Who are our stakeholders and what are their values, beliefs, and priorities?

Stakeholders refer to the people who are directly or indirectly impacted by the technology. In the case of RO-MAN’s home robot, we want to consider:

- Who is in the household and what is important to them in how they live their day to day?

- What are the possible interactions within the household members and between the householder members and the robot?

- How will the robot interact with the various stakeholders?

- What are the goals and values of each stakeholder? How do the stakeholders expect to interact with the robot? What do they expect to gain from the robot?

- What are the value tensions presented by the home robot and social context?

Once we’ve reviewed the values of each stakeholder identified in the previous step, we may notice that some of their values may be in conflict with one another. As such, we need to identify these value tensions because they can lead to ethical issues.

Here are some questions that can prompt us to think about value tensions:

- Who was involved in the decision of purchasing the robot? What were their goals in introducing the robot to the household?

- What is the cultural context or background for this particular household? What societal values could impact stakeholders’ individual beliefs and actions?

- What might the different stakeholders argue about? For example, what might the teenage daughter and the mother disagree about in regards to the robot’s capabilities?

- How will the robot create or relieve conflict in the household?

In some cases, value tensions may indicate a clear moral tradeoff, such that two values or goals conflict and one must be prioritized over another. The challenge is therefore to design solutions that fairly balance stakeholder interests while respecting their fundamental rights.

- How can we resolve the identified value tensions?

Focusing on these value tensions, we can begin to brainstorm how these conflicts can be addressed and at what level they should be addressed at. In particular, we need to determine whether a value tension can be resolved at a systems or technical level. For example, if the mother does not trust her daughter’s boyfriend, will the presence and actions of the home robot address the root of the problem (i.e. distrust)? Most likely not, but the robot may alleviate or exacerbate the issue. Therefore, we need to consider how the tension may manifest in more granular ways—how can we ensure that the robot appropriately navigates trust boundaries of the mother-boyfriend relationship? The robot must protect the privacy of all stakeholders, safeguard their personal items, abide by the laws, and respect other social norms.

When developing solutions, we can begin by asking ourselves:

- What level is the value tension occurring at, and what level(s) of solutions are accessible to the competition’s design parameters?

- Which actions from the robot will produce the most good and do the least harm?

- How can we manipulate the functions of the robot to address ethical challenges? For instance:

- How might the robot’s speech functions impact the identified value tensions?

- In what ways should the robot’s movements be limited to respect stakeholders’ privacy and personal spaces?

- How can design solutions address all stakeholders’ values?

- How can we maximize the positive impact of the design to address as many ethical challenges as possible?

What does the public think about the scenarios and approaches?

Often the public voice is missing in roboethics spaces, and we seek to engage the public in tackling these ethical challenges. To present the participants’ ethical designs to a broader audience, the Open Roboethics Institute will be running a public poll and awarding a Citizen’s Award to the team with the most votes. If you are interested in learning about and potentially judging their solutions, we encourage you to participate in the vote next month. We look forward to hearing from you!

To learn more about the roboethics competition at RO-MAN 2021, please visit https://competition.raiselab.ca. If you have any questions about the ORI Foresight into AI Ethics Toolkit, contact us at contact@openroboethics.org.

Additional Resources

RO-MAN 2021 Roboethics Competition: Bringing ethical robots into the home

In 1984, Heathkit presented HERO Jr. as the first robot that could be used in households to perform a variety of tasks, such as guarding people’s homes, setting reminders, and even playing games. Following this development, many companies launched affordable “smart robots” that could be used within the household. Some of these technologies, like Google Home, Amazon Echo and Roomba, have become household staples; meanwhile, other products such as Jibo, Aniki, and Kuri failed to successfully launch despite having all the necessary resources.

By Marshall Astor – flickr.com, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=5531066

Why were these robots shut down? Why aren’t there more social and service robots in households, particularly with the rising eldery population and increasing number of full-time working parents? The simple answer is that most of these personal robots do not work well—but this is not necessarily because we do not have the technological capacity to build highly functional robots.

Technologists have accomplished amazing physical tasks with robots such as a humanoid robot that can perform gymnastics movements or a robotic dog that traverses through rough trails. However, as of now we cannot guarantee that these robots/personal assistants act appropriately in the complex and sensitive social dynamics of a household. This poses a significant obstacle in developing domestic service robots because companies would be liable for any harms a socially inappropriate robot causes. As robots become more affordable and feasible technically, the challenge of designing robots that act in accordance with context-specific social norms becomes increasingly pronounced. Researchers in human-robot interaction and roboethics have attempted to resolve this issue for the past few decades, and while progress has been made, there is an urgent need to address the ethical implications of service robots in practice.

As an attempt to take a more solution-focused path for these challenges, we are happy to share a completely new competition with our readers. This year, the Roboethics to Design & Development competition will take place as a part of RO-MAN—an international conference on robot and human interactive communication. The competition, the first and only one of its kind, fulfills a need for interactive education on roboethics.

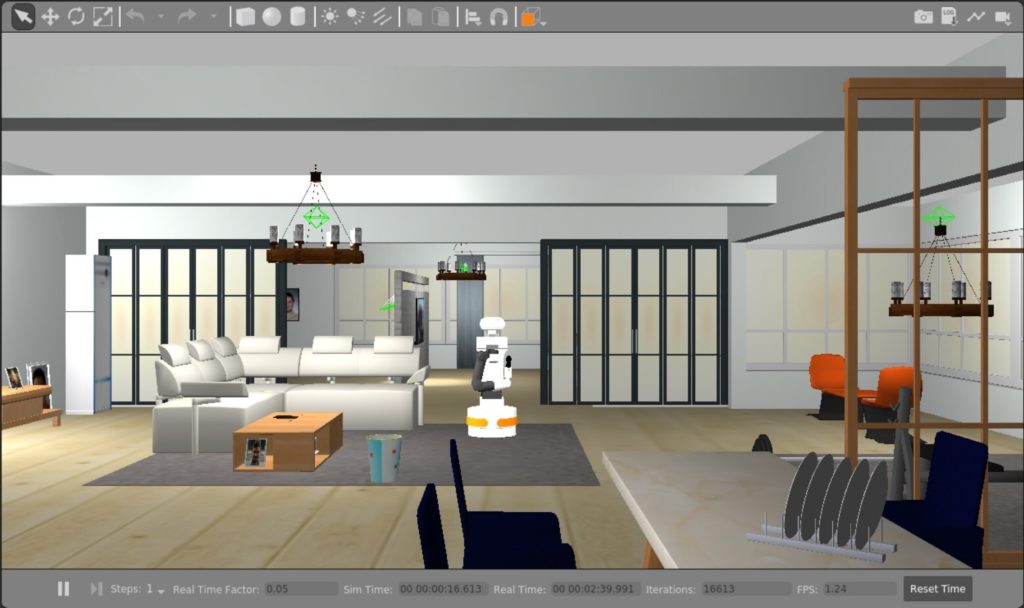

In partnership with RoboHub at the University of Waterloo, the competition organizers designed a virtual environment where participating teams will develop a robot that fetches objects in a home. The household is composed of a variety of personas—a single mother who works as a police officer, a teenage daughter, her college-aged boyfriend, a baby, and a dog. For example, design teams will need to consider how a home robot may respond to the daughter’s request to take her parent’s credit card. In this ethical conundrum, should the robot obey the daughter, and would the robot be responsible if the daughter were to use the credit card without her mom’s permission?

How can we identify and address ethical challenges presented by a home robot?

Participants are challenged to tackle the long-standing problem of how we can design a safe and ethical robot in a dynamic environment where values, beliefs, and priorities may be in conflict. With submissions from around the world, it will be fascinating to see how solutions may differ and translate across cultures.

It is important to recognize that there is a void when searching for standards and ethical rules in robotics. In an attempt to address this void, various toolkits have been developed to guide technologists in identifying and resolving ethical challenges. Here are some steps from the Foresight into AI Ethics Toolkit that will be helpful in designing an ethical home robot:

- Who are our stakeholders and what are their values, beliefs, and priorities?

Stakeholders refer to the people who are directly or indirectly impacted by the technology. In the case of RO-MAN’s home robot, we want to consider:

- Who is in the household and what is important to them in how they live their day to day?

- What are the possible interactions within the household members and between the householder members and the robot?

- How will the robot interact with the various stakeholders?

- What are the goals and values of each stakeholder? How do the stakeholders expect to interact with the robot? What do they expect to gain from the robot?

- What are the value tensions presented by the home robot and social context?

Once we’ve reviewed the values of each stakeholder identified in the previous step, we may notice that some of their values may be in conflict with one another. As such, we need to identify these value tensions because they can lead to ethical issues.

Here are some questions that can prompt us to think about value tensions:

- Who was involved in the decision of purchasing the robot? What were their goals in introducing the robot to the household?

- What is the cultural context or background for this particular household? What societal values could impact stakeholders’ individual beliefs and actions?

- What might the different stakeholders argue about? For example, what might the teenage daughter and the mother disagree about in regards to the robot’s capabilities?

- How will the robot create or relieve conflict in the household?

In some cases, value tensions may indicate a clear moral tradeoff, such that two values or goals conflict and one must be prioritized over another. The challenge is therefore to design solutions that fairly balance stakeholder interests while respecting their fundamental rights.

- How can we resolve the identified value tensions?

Focusing on these value tensions, we can begin to brainstorm how these conflicts can be addressed and at what level they should be addressed at. In particular, we need to determine whether a value tension can be resolved at a systems or technical level. For example, if the mother does not trust her daughter’s boyfriend, will the presence and actions of the home robot address the root of the problem (i.e. distrust)? Most likely not, but the robot may alleviate or exacerbate the issue. Therefore, we need to consider how the tension may manifest in more granular ways—how can we ensure that the robot appropriately navigates trust boundaries of the mother-boyfriend relationship? The robot must protect the privacy of all stakeholders, safeguard their personal items, abide by the laws, and respect other social norms.

When developing solutions, we can begin by asking ourselves:

- What level is the value tension occurring at, and what level(s) of solutions are accessible to the competition’s design parameters?

- Which actions from the robot will produce the most good and do the least harm?

- How can we manipulate the functions of the robot to address ethical challenges? For instance:

- How might the robot’s speech functions impact the identified value tensions?

- In what ways should the robot’s movements be limited to respect stakeholders’ privacy and personal spaces?

- How can design solutions address all stakeholders’ values?

- How can we maximize the positive impact of the design to address as many ethical challenges as possible?

What does the public think about the scenarios and approaches?

Often the public voice is missing in roboethics spaces, and we seek to engage the public in tackling these ethical challenges. To present the participants’ ethical designs to a broader audience, the Open Roboethics Institute will be running a public poll and awarding a Citizen’s Award to the team with the most votes. If you are interested in learning about and potentially judging their solutions, we encourage you to participate in the vote next month. We look forward to hearing from you!

To learn more about the roboethics competition at RO-MAN 2021, please visit https://competition.raiselab.ca. If you have any questions about the ORI Foresight into AI Ethics Toolkit, contact us at contact@openroboethics.org.

Additional Resources

Swarms of tiny dumb robots found to carry out sophisticated actions

An autonomous system to assemble reconfigurable robotic structures in space

Finding the Staff Needed: Connected Factories Driving Demand for Robotics Engineers

New algorithm flies drones faster than human racing pilots

To be useful, drones need to be quick. Because of their limited battery life they must complete whatever task they have – searching for survivors on a disaster site, inspecting a building, delivering cargo – in the shortest possible time. And they may have to do it by going through a series of waypoints like windows, rooms, or specific locations to inspect, adopting the best trajectory and the right acceleration or deceleration at each segment.

Algorithm outperforms professional pilots

The best human drone pilots are very good at doing this and have so far always outperformed autonomous systems in drone racing. Now, a research group at the University of Zurich (UZH) has created an algorithm that can find the quickest trajectory to guide a quadrotor – a drone with four propellers – through a series of waypoints on a circuit. “Our drone beat the fastest lap of two world-class human pilots on an experimental race track”, says Davide Scaramuzza, who heads the Robotics and Perception Group at UZH and the Rescue Robotics Grand Challenge of the NCCR Robotics, which funded the research.

“The novelty of the algorithm is that it is the first to generate time-optimal trajectories that fully consider the drones’ limitations”, says Scaramuzza. Previous works relied on simplifications of either the quadrotor system or the description of the flight path, and thus they were sub-optimal. “The key idea is, rather than assigning sections of the flight path to specific waypoints, that our algorithm just tells the drone to pass through all waypoints, but not how or when to do that”, adds Philipp Foehn, PhD student and first author of the paper in Science Robotics.

External cameras provide position information in real-time

The researchers had the algorithm and two human pilots fly the same quadrotor through a race circuit. They employed external cameras to precisely capture the motion of the drones and – in the case of the autonomous drone – to give real-time information to the algorithm on where the drone was at any moment. To ensure a fair comparison, the human pilots were given the opportunity to train on the circuit before the race. But the algorithm won: all its laps were faster than the human ones, and the performance was more consistent. This is not surprising, because once the algorithm has found the best trajectory it can reproduce it faithfully many times, unlike human pilots.

Before commercial applications, the algorithm will need to become less computationally demanding, as it now takes up to an hour for the computer to calculate the time-optimal trajectory for the drone. Also, at the moment, the drone relies on external cameras to compute where it was at any moment. In future work, the scientists want to use onboard cameras. But the demonstration that an autonomous drone can in principle fly faster than human pilots is promising. “This algorithm can have huge applications in package delivery with drones, inspection, search and rescue, and more”, says Scaramuzza.

Literature

New algorithm flies drones faster than human racing pilots

The Elimination Tide of Physical Stores: Rise of E-commerce

What is the best simulation tool for robotics?

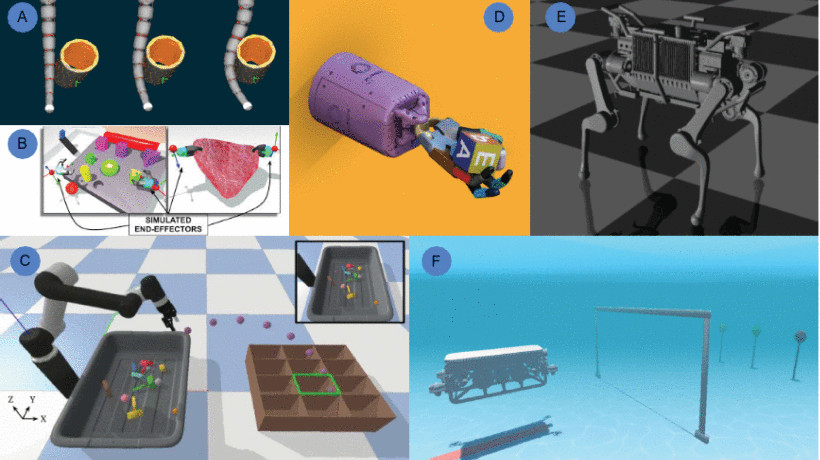

What is the best simulation tool for robotics? This is a hard question to answer because many people (or their companies) specialize in one tool or another. Some simulators are better at one aspect of robotics than at others. When I’m asked to recommend the best simulation tool for robotics I have to find an expert and hope that they are current and across a wide range of simulation tools in order to give me the best advice, which was why I took particular note of the recent review paper from Australia’s CSIRO, “A Review of Physics Simulators for Robotics Applications” by Jack Collins, Shelvin Chand, Anthony Vanderkop, and David Howard, published in IEEE Access (Volume: 9).

“We have compiled a broad review of physics simulators for use within the major fields of robotics research. More specifically, we navigate through key sub-domains and discuss the features, benefits, applications and use-cases of the different simulators categorised by the respective research communities. Our review provides an extensive index of the leading physics simulators applicable to robotics researchers and aims to assist them in choosing the best simulator for their use case.”

Simulation underpins robotics because it’s cheaper, faster and more robust than real robots. While there are some guides that benchmark simulators against real world tasks there isn’t a comprehensive review. A more thorough review can address gaps and needs in research and research challenges for simulation. The authors focus on seven sub-domains: Mobile Ground Robotics; Manipulation; Medical Robotics; Marine Robotics; Aerial Robotics; Soft Robotics and Learning for Robotics.

I’m going to cut to the chase and provide a copy of the final comparison tables of each sub-domain but for anyone interested in utilizing these recommendations, then I recommend reading the rationale behind the rankings in the full review article. The authors also consider whether or not a simulator is actively supported. Handy to know! And the paper is also an excellent source of information about various historic and current robotics competitions.

Mobile Ground Robotics:

TABLE 1 Feature Comparison Between Popular Robotics Simulators

TABLE 2 Feature Comparison Between Popular Robotics Simulators Used for Mobile Ground Robotics

Manipulation:

TABLE 3 Feature Comparison for Popular Robotics Simulators Used for Manipulation

Medical Robotics:

TABLE 4 Feature Comparison of Popular Robotics Simulators Used for Medical Robotics

Marine Robotics:

TABLE 5 Feature Comparison of Popular Simulators Used for Marine Robotics

Aerial Robotics:

TABLE 6 Feature Comparison of Popular Simulators Used for Aerial Robotics

Soft Robotics:

TABLE 7 Feature Comparison of Popular Simulators Used for Soft Robotics

Learning for Robotics:

TABLE 8 Feature Comparison of Popular Simulators Used in Learning for Robotics

Conclusions:

As robotics makes more use of deep learning, simulators that can deal with data on the fly become necessary, and also a potential solution for simulation problems regarding points of contact or collisions. Rather than utilize multiple simulation methods to make a clearer abstraction of the real world in these boundary situations, the answer may be to insert neural networks trained to replicate the properties of difficult phenomena into the simulator. There is further discussion on differentiable simulation, levels of abstraction and the expansion of libraries, plug-ins, toolsets, benchmarking and algorithmic integration, all increasing both the utility and complexity of simulation for robotics.

As the field of simulation for robotics grows, so does the need for metrics that capture the accuracy of the real world representation. “Finally, we predict that we will see further research into estimating and modeling uncertainty of simulators.”

This may have been the first review article on simulation for robotics but hopefully not the last. There’s a clear need to study and measure the field. I found the sections on soft robotics and learning for robotics particularly interesting, as the paper discussed the difficulties of simulation in these fields. And please attribute any errors in this summary to my mistakes. Read the full review here: https://ieeexplore.ieee.org/document/9386154