Climate-neutral, highly economical production through AI and digitization

Robot Talk Episode 47 – Helmut Hauser

Claire chatted to Helmut Hauser from the University of Bristol all about soft robotics, sensing, and smart robot bodies.

Helmut Hauser is an Associate Professor in Robotics at the University of Bristol and the Bristol Robotics Laboratory. He is also the Director of the EPSRC Centre of Doctoral Training for Robotics and Autonomous Systems. Helmut’s research is focused on morphological computation and soft robotics. In particular, he is interested in understanding the underlying principles of how biological systems exploit their complex physical bodies to facilitate sensing, controlling and learning, and how these principles can be employed to design better bodies to build better robots.

Scurrying centipedes inspire many-legged robots that can traverse difficult landscapes

An architecture to coordinate the behavior of different robots in a team

Choosing a Robotic Spindle for Deburring

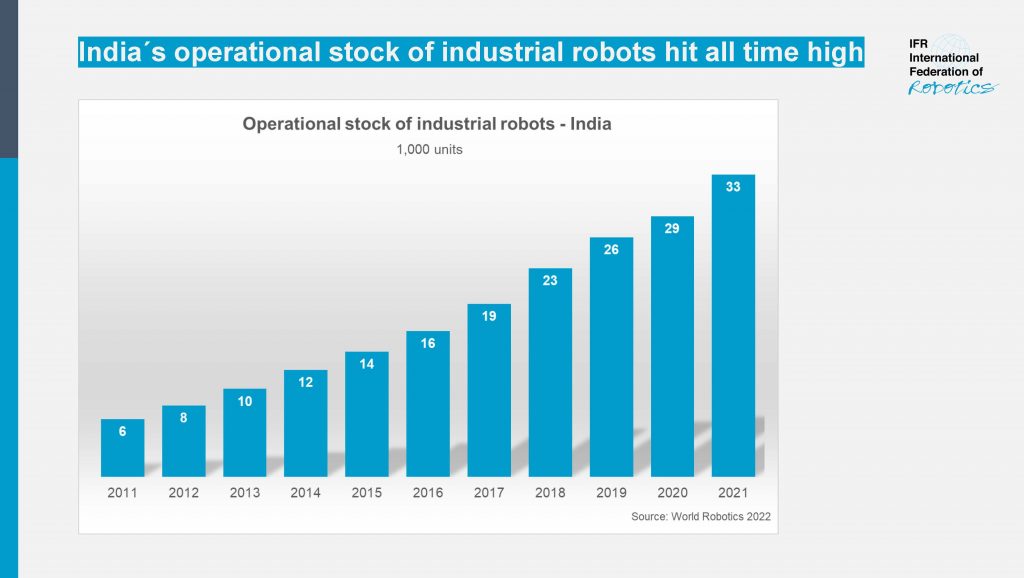

India’s robot boom hits all-time high

India´s operational stock of industrial robots hit all time high.

Sales of industrial robots in India reached a new record of 4,945 units installed. This is an increase of 54 percent compared to the previous year (2020: 3,215 units). In terms of annual installations, India now ranks in tenth position worldwide. These are findings of the report World Robotics, presented by the International Federation of Robotics (IFR).

“India is one of the world’s fastest-growing industrial economies,” says Marina Bill, President of the International Federation of Robotics. “Within five years, the operational stock of industrial robots has more than doubled, to reach 33,220 units in 2021. This corresponds to an average annual growth rate of 16% since 2016.”

Today, India is the world’s fifth largest economy measured by manufacturing output. According to World Bank data, India´s manufacturing value added in 2021 was USD 443.9 billion, a 21.6% increase from 2020.

The automotive industry remains the largest customer for the robotics industry in India with a share of 31% in 2021. Installations more than doubled to 1,547 units (+108%). The general industry in India is led by the metal industry with 308 units (-9%), the rubber and plastics industry with 246 units (+27%) and the electrical/electronics industry with 215 units (+98%).

Impressive potential for India

The long-term potential of robotics in India becomes clearer when compared to China: India´s robot density in the automotive industry, which is the number of industrial robots per 10,000 employees, reached 148 robots in 2021. China´s robot density hit 131 units in 2010 and skyrocketed to 772 units in 2021.

The Indian government supports growth in the industrial sector as one of the vital figures that affect the Gross Domestic Product (GDP). Today, the country´s GDP of about USD 3 trillion ranks in fifth place, head-to-head with the UK and France – behind Germany, Japan, China and the USA – the International Monetary Fund reports.

Outlook for India

“As a result of the recent supply chain disruption, companies are rethinking their nearshoring strategies in Southeast Asia,” says Marina Bill. “India has traditionally been a popular destination for nearshoring in the manufacturing segment. The Indian government wants the country to be considered for new diversification options such as friendshoring, which is partnering with countries that share similar values and interests.”

The manufacturing sector is also expected to benefit from the government’s initiatives to boost its competitiveness and attractiveness for investors. The Production Linked Incentive (PLI) scheme, for example, currently set to run until 2025, subsidizes companies that create production capacity in India in robot customer industries like automotive, metal, pharmaceuticals, and food processing.

Robots help to create new jobs

New manufacturing capacities in India are an important step to provide adequate education and employment opportunities for its people: According to projections of the United Nations, India now has a population of 1,4 billion, surpassing China for the first time. This means that India has a large and young workforce that can drive economic growth and innovation. India is expected to have the largest working-age population in the world by 2027.

A new hydrogel-based skin with tactile sensing capabilities

An Introduction To Plug-and-Play Motion Subsystems

Knocked down but not defeated: Robots learn soccer

Open-source platform simulates wildlife for soft robotics designers

Talking AUTOMATE 2023 with ATI

Novel system uses reinforcement learning to teach robotic cars to speed

Robot fish makes splash with motion breakthrough

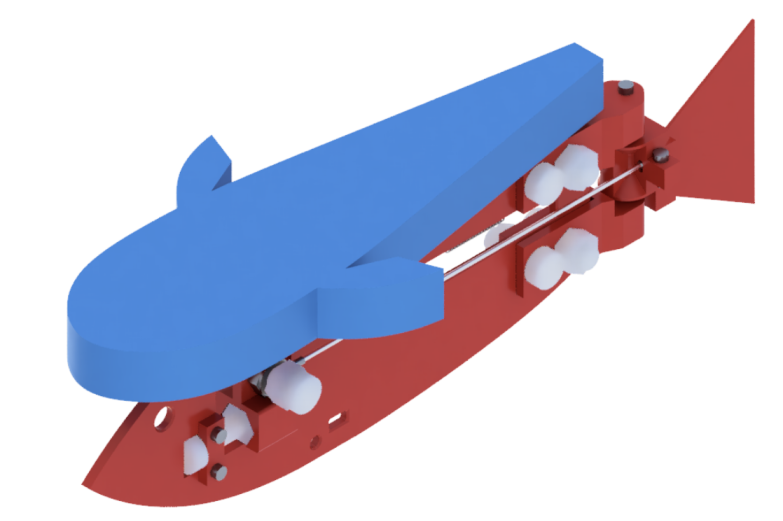

Robot fish. Image credit: Tsam Lung You

The robot fish was fitted with a twisted and coiled polymer (TCP) to drive it forward, a light-weight low cost device that relies on temperature change to generate movement, which also limits its speed.

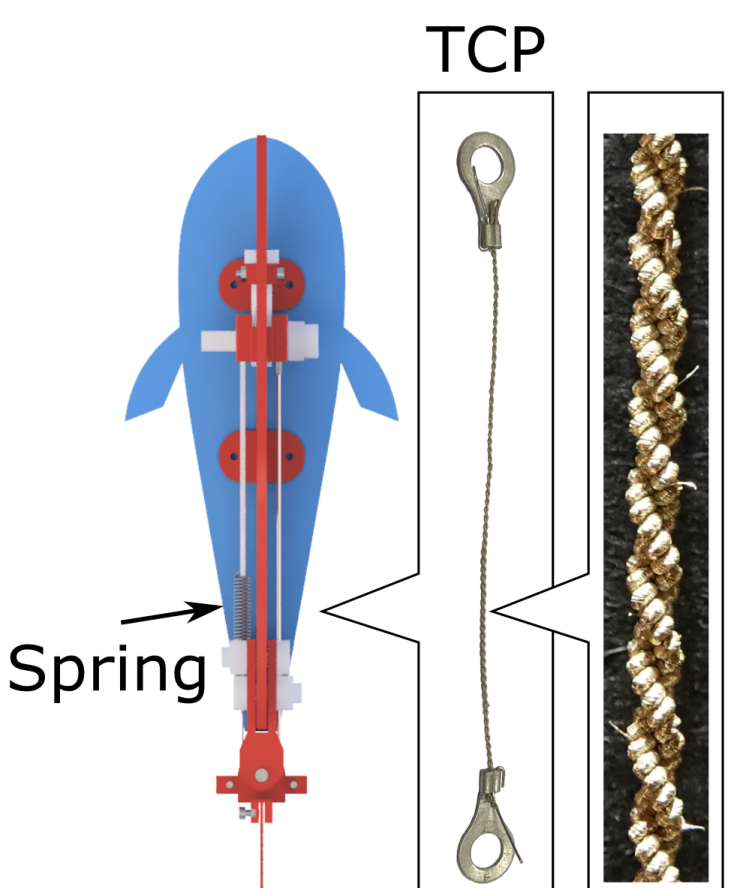

A TCP works by contracting like muscles when heated, converting the energy into mechanical motion. The TCP used in this work is warmed by Joule heating – the pass of current through an electrical conductor produces thermal energy and heats up the conductor. By minimising the distance between the TCP on one side of the robot fish and the spring on the other, this activates the fin at the rear, enabling the robot fish to reach new speeds. The undulating flapping of its rear fin was measured at a frequency of 2Hz, two waves per second. The frequency of the electric current is the same as the frequency of tail flap.

The findings, published at the 6th IEEE-RAS International Conference on Soft Robotics (RoboSoft 2023), provide a new route to raising the actuation – the action of causing a machine or device to operate – frequency of TCPs through thermomechanical design and shows the possibility of using TCPs at high frequency in aqueous environments.

Lead author Tsam Lung You from Bristol’s Department of Engineering Mathematics said: “Twisted and coiled polymer (TCP) actuator is a promising novel actuator, exhibiting attractive properties of light weight, low-cost high energy density and simple fabrication process.

“They can be made from very easily assessable materials such as a fishing line and they contract and provide linear actuation when heated up. However, because of the time needed for heat dissipation during the relaxation phase, this makes them slow.”

By optimising the structural design of the TCP-spring antagonistic muscle pair and bringing their anchor points closer together, it allowed the posterior fin to swing at a larger angle for the same amount of TCP actuation.

Antagonistic muscles. Image credit: Tsam Lung You

Although this requires greater force, TCP is a strong actuator with high work energy density, and is still able to drive the fin.

Until now, TCPs have been mostly used for applications such as wearable devices and robotic hands. This work opens up more areas of application where TCP can be used, such as marine robots for underwater exploration and monitoring.

Tsam Lung You added: “Our robotic fish swam at the fastest actuation frequency found in a real TCP application and also the highest locomotion speed of a TCP application so far.

“This is really exciting as it opens up more opportunities of TCP application in different areas.”

The team now plan to expand the scale and develop a knifefish-inspired TCP-driven ribbon fin robot that can swim agilely in water.

NCCR Robotics: A documentary

This short film documents some of the most innovative projects that emerged from the work of NCCR Robotics, the Swiss-wide consortium coordinated from 2010 to 2022 by EPFL professor Dario Floreano and ETHZ professor Robert Riener, including other major research institutions across Switzerland.

Shot over the course of six months in Lausanne, Geneva, Zurich, Wangen an der Aare, Leysin, Lugano, the documentary is a unique look at the state of the art of medical, educational and rescue robotics, and at the specific contributions that Swiss researchers have given to the field over the last decade. In addition to showing the robots in action, the film features extended interviews with top experts including Stéphanie Lacour, Silvestro Micera, Davide Scaramuzza, Robert Riener, Pierre Dillenbourg, Margarita Chli, Dario Floreano.

Produced by NCCR Robotics and Viven.