PACK EXPO 2019 – Piab

Top Tips for Conducting Robotics Field Research

Blue Ocean Robotics Acquires World-Leading Telepresence Robot Beam

Robots can now learn to swarm on the go

A new generation of swarming robots which can independently learn and evolve new behaviours in the wild is one step closer, thanks to research from the University of Bristol and the University of the West of England (UWE).

The team used artificial evolution to enable the robots to automatically learn swarm behaviours which are understandable to humans. This new advance published this Friday in Advanced Intelligent Systems, could create new robotic possibilities for environmental monitoring, disaster recovery, infrastructure maintenance, logistics and agriculture. Read More

A miniature stretchable pump for the next generation of soft robots

By Laure-Anne Pessina and Nicola Nosengo

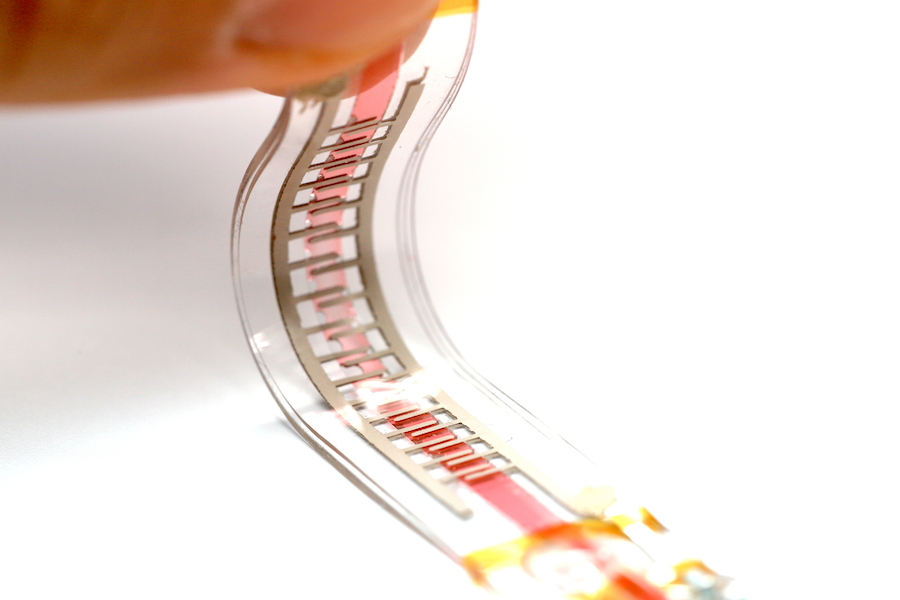

Scientists at EPFL have developed a tiny pump that could play a big role in the development of autonomous soft robots, lightweight exoskeletons and smart clothing. Flexible, silent and weighing only one gram, it is poised to replace the rigid, noisy and bulky pumps currently used. The scientists’ work has just been published in Nature.

Soft robots have a distinct advantage over their rigid forebears: they can adapt to complex environments, handle fragile objects and interact safely with humans. Made from silicone, rubber or other stretchable polymers, they are ideal for use in rehabilitation exoskeletons – such as the ones being developed in the NCCR Robotics “Wearable Robotics” research line – and robotic clothing. Soft bio-inspired robots could one day be deployed to explore remote or dangerous environments.

Most soft robots are actuated by rigid, noisy pumps that push fluids into the machines’ moving parts. Because they are connected to these bulky pumps by tubes, these robots have limited autonomy and are cumbersome to wear at best.

Cutting soft robots’ tether

Researchers in EPFL’s Soft Transducers Laboratory (LMTS) and Laboratory of Intelligent Systems (LIS – led by NCCR Robotics Director Dario Floreano), in collaboration with researchers at the Shibaura Institute of Technology in Tokyo, Japan, have developed the first entirely soft pump – even the electrodes are flexible. Weighing just one gram, the pump is completely silent and consumes very little power, which it gets from a 2 cm by 2 cm circuit that includes a rechargeable battery. “If we want to actuate larger robots, we connect several pumps together,” says Herbert Shea, the director of the LMTS.

This innovative pump could rid soft robots of their tethers. “We consider this a paradigm shift in the field of soft robotics,” adds Shea.

Soft pumps can also be used to circulate liquids in thin flexible tubes embedded in smart clothing, leading to garments that can actively cool or heat different regions of the body. That would meet the needs of surgeons, athletes and pilots, for example.

How does it work?

The soft and stretchable pump is based on the physical mechanism used today to circulate the cooling liquid in systems like supercomputers. The pump has a tube-shaped channel, 1mm in diameter, inside of which rows of electrodes are printed. The pump is filled with a dielectric liquid. When a voltage is applied, electrons jump from the electrodes to the liquid, giving some of the molecules an electrical charge. These molecules are subsequently attracted to other electrodes, pulling along the rest of the fluid through the tube with them. “We can speed up the flow by adjusting the electric field, yet it remains completely silent,” says Vito Cacucciolo, a post-doc at the LMTS and the lead author of the study.

Developing artificial muscles in Japan

The researchers have successfully implanted their pump in a type of robotic finger widely used in soft robotics labs. They are now collaborating with Koichi Suzumori’s laboratory in Japan, which is developing fluid-driven artificial muscles and flexible exoskeletons.

The EPFL team has also fitted a fabric glove with tubes and shown that it is possible to heat or cool regions of the glove as desired using the pump. “It works a little like your home heating and cooling system” says Cacucciolo. This application has already sparked interest from a number of companies.

Literature

V. Cacucciolo, J. Shintake, Y. Kuwajima, S. Maeda, D. Floreano, H. Shea, “Stretchable pumps for soft machines”, Nature, vol. 572, no 7769, Aug. 2019.

doi: 10.1038/s41586-019-1479-6

Suit up with a robot to walk AND run more easily

By Benjamin Boettner

Between walking at a leisurely pace and running for your life, human gaits can cover a wide range of speeds. Typically, we choose the gait that allows us to consume the least amount of energy at a given speed. For example, at low speeds, the metabolic rate of walking is lower than that of running in a slow jog; vice versa at high speeds, the metabolic cost of running is lower than that of speed walking.

Researchers in academic and industry labs have previously developed robotic devices for rehabilitation and other areas of life that can either assist walking or running, but no untethered portable device could efficiently do both. Assisting walking and running with a single device is challenging because of the fundamentally different biomechanics of the two gaits. However, both gaits have in common an extension of the hip joint, which starts around the time when the foot comes in contact with the ground and requires considerable energy for propelling the body forward.

As reported today in Science, a team of researchers at Harvard’s Wyss Institute for Biologically Inspired Engineering and John A. Paulson School of Engineering and Applied Sciences (SEAS), and the University of Nebraska Omaha now has developed a portable exosuit that assists with gait-specific hip extension during both walking and running. Their lightweight exosuit is made of textile components worn at the waist and thighs, and a mobile actuation system attached to the lower back which is controlled by an algorithm that can robustly detect the transition from walking to running and vice versa.

The team first showed that the exosuit worn by users in treadmill-based indoor tests, on average, reduced their metabolic costs of walking by 9.3% and of running by 4% compared to when they were walking and running without the device. “We were excited to see that the device also performed well during uphill walking, at different running speeds and during overground testing outside, which showed the versatility of the system,” said Conor Walsh, Ph.D., who led the study. Walsh is a Core Faculty member of the Wyss Institute, the Gordon McKay Professor of Engineering and Applied Sciences at SEAS, and Founder of the Harvard Biodesign Lab. “While the metabolic reductions we found are modest, our study demonstrates that it is possible to have a portable wearable robot assist more than just a single activity, helping to pave the way for these systems to become ubiquitous in our lives,” said Walsh.

The hip exosuit was developed as part of the Defense Advanced Research Projects Agency (DARPA)’s former Warrior Web program and is the culmination of years of research and optimization of the soft exosuit technology by the team. A previous multi-joint exosuit developed by the team could assist both the hip and ankle during walking, and a medical version of the exosuit aimed at improving gait rehabilitation for stroke survivors is now commercially available in the US and Europe, via a collaboration with ReWalk Robotics.

The team’s most recent hip-assisting exosuit is designed to be simpler and lighter weight compared to their past multi-joint exosuit. It assists the wearer via a cable actuation system. The actuation cables apply a tensile force between the waist belt and thigh wraps to generate an external extension torque at the hip joint that works in concert with the gluteal muscles. The device weighs 5kg in total with more than 90% of its weight located close to the body’s center of mass. “This approach to concentrating the weight, combined with the flexible apparel interface, minimizes the energetic burden and movement restriction to the wearer,” said co-first-author Jinsoo Kim, a SEAS graduate student in Walsh’s group. “This is important for walking, but even more so for running as the limbs move back and forth much faster.” Kim shared the first-authorship with Giuk Lee, Ph.D., a former postdoctoral fellow on Walsh’s team and now Assistant Professor at Chung-Ang University in Seoul, South Korea.

A major challenge the team had to solve was that the exosuit needed to be able to distinguish between walking and running gaits and change its actuation profiles accordingly with the right amount of assistance provided at the right time of the gait cycle.

To explain the different kinetics during the gait cycles, biomechanists often compare walking to the motions of an inverted pendulum and running to the motions of a spring-mass system. During walking, the body’s center of mass moves upward after heel-strike, then reaches maximum height at the middle of the stance phase to descend towards the end of the stance phase. In running, the movement of the center of mass is opposite. It descends towards a minimum height at the middle of the stance phase and then moves upward towards push-off.

“We took advantage of these biomechanical insights to develop our biologically inspired gait classification algorithm that can robustly and reliably detect a transition from one gait to the other by monitoring the acceleration of an individual’s center of mass with sensors that are attached to the body,” said co-corresponding author Philippe Malcolm, Ph.D., Assistant Professor at University of Nebraska Omaha. “Once a gait transition is detected, the exosuit automatically adjusts the timing of its actuation profile to assist the other gait, as we demonstrated by its ability to reduce metabolic oxygen consumption in wearers.”

In ongoing work, the team is focused on optimizing all aspects of the technology, including further reducing weight, individualizing assistance and improving ease of use. “It is very satisfying to see how far our approach has come,” said Walsh, “and we are excited to continue to apply it to a range of applications, including assisting those with gait impairments, industry workers at risk of injury performing physically strenuous tasks, or recreational weekend warriors.”

“This breakthrough study coming out of the Wyss Institute’s Bioinspired Soft Robotics platform gives us a glimpse into a future where wearable robotic devices can improve the lives of the healthy, as well as serve those with injuries or in need of rehabilitation,” said Wyss Institute Founding Director Donald Ingber, M.D., Ph.D., who is also the Judah Folkman Professor of Vascular Biology at Harvard Medical School, the Vascular Biology Program at Boston Children’s Hospital, and Professor of Bioengineering at SEAS.

Other authors on the study are past and present members of Walsh’s team, including data analyst Roman Heimgartner; Research Fellow Dheepak Arumukhom Revi; Control Engineer Nikos Karavas, Ph.D.; Functional Apparel Designer Danielle Nathanson; Robotics Engineer Ignacio Galiana, Ph.D.; Robotics Engineer Asa Eckert-Erdheim; Electromechanical Engineer Patrick Murphy; Engineer David Perry; Software Engineer Nicolas Menard, and graduate student Dabin Kim Choe. The study was funded by the Defense Advanced Research Projects Agency’s Warrior Web Program, the National Science Foundation and Harvard’s Wyss Institute for Biologically Inspired Engineering.

Autonomous Navigation

To navigate its environment, a robot must be either remote controlled, preprogrammed in a known unchanging environment, or it must be able to do this autonomously. To be able to navigate autonomously a robot must be able to not only continuously model and update its environment, which can be static and dynamic, but also be able to determine the best path to take based on this model and its own instantaneous location. Based on this model, the navigation algorithm must be able to predict the future states of all the obstacles and objects in the environment. The necessary inputs to overcome these challenges are obtained through sensors, mainly camera but can involve other sensors such as infrared, ultrasonic, LiDAR and more.

Although the background was laid before, the technology saw fast improvement after 2000s. DARPA Grand challenge for autonomous vehicles for example, took it one step ahead each year, until finally it was discontinued due to completion of a path in its entirety was not a challenge anymore. Today we see autonomous navigation technology in cars, trucks and other robotic systems including humanoid robots (androids), various domestic robots such as security, delivery, warehouse robots, to varying degrees. Once full autonomy in traffic is achieved as a widespread application, the technology is expected to transform our life in various ways.

Post Date: December 7th, 2022

Advanced Machine Learning Software for Robotic Systems

Training Surgeons to Use Robotic Systems

Training Surgeons to Use Robotic Systems

Service Robotics to Reach Greater Feats With Innovation and Advanced Technologies

Service Robotics to Reach Greater Feats With Innovation and Advanced Technologies

Segway-Ninebot Unveils New AI-powered Products, Delivering Take-out with Low-cost DeliveryBots

Curvedrive – innovative fluid drive for applications in robotics, exoskeletons and mechanical engineering

Sometimes, robot joints with pneumatic or hydraulic drives are technically complex in design, partly with linear cylinders, pivot points and many mechanical parts.

Many constructive solutions currently present themselves in such a way that used linear cylinders with a pivot bearing, bearing block and swivel head pivot the parts with the help of levers and pivot bearings. This is very unfavorable if uniform forces are to be generated over the entire movement sequence. In the Curvedrive, on the other hand, the same force always acts on the component to be moved – as indicated in the picture called “Alternative”.

Different variants of the Curvedrive with piston rod, as double cylinder and also with guide carriage are executed with the commercial piston diameters.

In addition, various housing versions are available, which are required for the realization of pivoting angles from 10° to 150°, special versions and multi-position cylinders with angles of 180° and more.

The drives in the video have swivel angles of about 90 “, but variants with swivel angles of 120° to 150° are also possible for knee or elbow joints. The movements of the Curvedrive as a combination of two drives can be seen in the video.

Link to Youtube video: https://www.youtube.com/watch?v=ioZAbDBmwPE

The pivotal movement may be about a single axis, such as an elbow or knee joint. If Curvedrives are assembled in a combined manner, then movable drives can be represented around several axes, which are suitable, for example, as a shoulder joint for robots – as indicated in the picture called “Application for robot joints”.

Curvedrive is a compact and combinable unit in which the joint is at the same time also the rotary actuator. Servopneumatic or servohydraulic drives can be implemented in combination with attached or integrated displacement or angle measuring systems, making them an alternative to purely electric servo drives.

The safety in the cooperation of humans and robots is ensured by the good adjustment and controllability of the forces, as well as uniform motion sequences.

The Curvedrive offers a wide range of possibilities for novel design and design concepts of innovative robotics models. Industrial robots for manufacturing and assembly tasks, as humanoid robots, helper for the people in household and service and as independently operating work and transport robots under difficult operating conditions for the completion of various tasks, or as a working machine that is operated by humans, are just a few examples from the wide range of applications:

- The Curvedrive offers as an alternative to conventional linear drives in specific applications.

- Work machines and vehicles with mobile pneumatics and hydraulics

- Enrichment for handling and automation components

- Curvedrive can be used both in robotics for small joint structures and in mechanical engineering for heavy and powerful motion sequences.

Web: https://www.bremer-kock.com

Youtube: https://www.youtube.com/watch?v=ioZAbDBmwPE

**************************************************************************************

The content above was provided to Roboticmagazine.Com by Bremer Kock company.

Robotic Magazine’s general note: The contents in press releases and user provided content that are published on this website were provided by their respective owners, and therefore the contents in these do not necessarily represent RoboticMagazine.Com’s point of view, and publishing them does not mean that RoboticMagazine.Com endorses the published product or service.

The post Curvedrive – innovative fluid drive for applications in robotics, exoskeletons and mechanical engineering appeared first on Roboticmagazine.