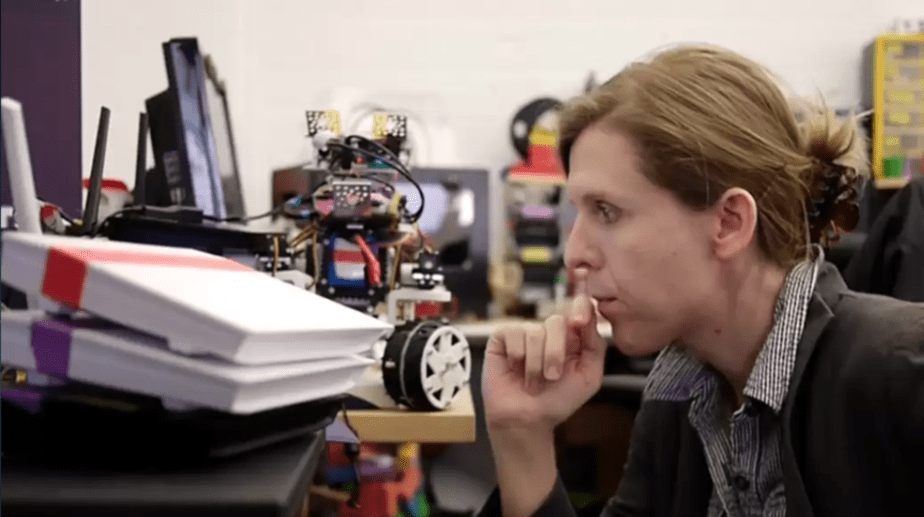

Jillian Ogle is the first ‘Roboticist in Residence’ at Co-Lab

Currently also featured on the cover of MAKE magazine, Jillian Ogle is a robot builder, game designer and the founder of Let’s Robot a live streaming interactive robotics community, where users can control real robots via chatroom commands, or put their on own robots online. Some users can even make money with their robots on the Let’s Robot platform which allows viewers to make micropayments to access some robots. All you need is a robot doing something that’s interesting to someone else, whether it’s visiting new locations or letting the internet shoot ping pong balls at you while you work!

As the first ‘Roboticist in Residence’ at Co-Lab in Oakland, Ogle has access to the all the equipment and 32,000 sq ft of space, providing her robotics community with a super large robot playground for her live broadcasts. And the company of fellow robot geeks. Co-Lab is the new coworking space at Circuit Launch supported by Silicon Valley Robotics, and provides mentors, advisors and community events, as well as electronics and robotics prototyping equipment.

You can meet Ogle at the next Silicon Valley Robotics speaker salon “The Future of Robotics is FUN” on Sept 4 2018. She’ll be joined by Circuit Launch COO Dan O’Mara and Mike Winter, Battlebot World Champion and founder of new competition ‘AI or Die’. Small and cheap phone powered robots are becoming incredibly intelligent and Ogle and Winter are at the forefront of pushing the envelope.

Ogle sees Let’s Robot as the start of a new type of entertainment, where the relationship between viewers and content are two-way and interactive. Particularly because robots can go places that some of us can’t, like the Oscars. Ogle has ironed out a lot of the problems with telepresence robotics including faster response time for two way commands. Plus it’s more entertaining than old school telepresence with robots able to take a range of actions in the real world.

While the majority of robots are still small and toylike, Ogle believes that this is just the beginning of the way we’ll interact with robots in the future. Interaction is Ogle’s strength, she started her career as an interactive and game designer, previously working at companies like Disney and was also a participant in Intel’s Software Innovators program.

“I started all this by building dungeons out of cardboard and foam in my living room. My background was in game design, so I’m like, ‘Let’s make it a game.’ There’s definitely a narrative angle you could push; there’s also the real-world exploration angle. But I started to realize it’s a little bigger than that, right? With this project, you can give people access to things they couldn’t access by themselves.” said Jillian talking to Motherboard.

Here are the instructions from Makezine for connecting your own robot to Let’s Robot. The robot side software is open source, and runs on most Linux-based computers. There is even an API that allows you to fully customize the experience. If you’re building your own, start here.

Most of the homebrew robots on Let’s Robot use the following components:

- Raspberry Pi or other single-board computer. The newest Raspberry Pi has onboard Wi-Fi, you just need to point it at your access point.

- SD card with Raspbian or NOOBS installed. You can follow our guide to get our software to run on your robot, and pair it with the site: letsrobot.tv/setup.

- Microcontroller, such as Arduino. The Adafruit motor hat is also popular.

- Camera to see

- Microphone to hear

- Speaker to let the robot talk

- Body to hold all the parts

- Motors and servos to move and drive around

- LEDs and sensors to make things interesting

- And a battery to power it all

A lot of devices and robots are already supported by Let’s Robot software, including the GoPiGo Robot, and Anki Cozmo. If you have an awesome robot just sitting on the shelf collecting some dust, this could be a great way to share it with everyone! There’s also a development kit called “Telly Bot” which works out of the box with the letsrobot.tv site. See you online!

The Next NBA Star Could Be a Robot

Testing a New Line of Motor and Gearbox Products With a Rotary Torque Sensor

Case Study: Increasing Solar Inspection Efficiency with Drones

Roadmapping the AI race to help ensure safe development of AGI

This article accompanies a visual roadmap which you can view and download here.

Why are roadmaps important?

Roadmapping is a useful tool to allow us to look into the future, predict different possible pathways, and identify areas that might present opportunities or problems. The aim is to visualise different scenarios in order to prepare, and avoid scenarios that might lead to an undesirable future or even worse, disaster. It is also an exercise for visualizing a desired future and finding the optimal path towards achieving it.

Introducing the roadmap

This roadmap depicts three hypothetical scenarios in the development of an artificial general intelligence (AGI) system, from the perspective of an imaginary company (C1). The main focus is on the AI race, where stakeholders strive to reach powerful AI, and its implications on safety. It maps out possible decisions made by key actors in various “states of affairs”, which lead to diverse outcomes. Traffic-light color coding is used to visualise the potential outcomes with green showing positive outcomes, red — negative and orange — in-between.

The aim of this roadmap is not to present the viewer with all possible scenarios, but with a few vivid examples. The roadmap is primarily focusing on AGI, which presumably will have a transformative potential and would be able to dramatically affect society [1].

This roadmap intentionally ventures into some of the extreme scenarios to provoke the discussion on AGI’s role in paradigm shifts.

Scenario 1 - AI race: dangerous AGI is developed

Assuming that the potential of AGI is so great, and being the first to create it could give an unprecedented advantage [2] [3], there is a possibility that an AGI could be deployed before it is adequately tested. In this scenario C1 creates AGI while others still race to complete the technology. This could lead to C1 becoming anxious, deploying the AGI before safety is assured, and losing control of it.

What happens next in this scenario would depend on the nature of the AGI created. If the recursive self-improvement of AGI continues too fast for developers to catch up, the future would be out of humanity’s hands. In this case, depending on the objectives and values of the AGI, it could lead to a doomsday scenario or a kind of coexistence, where some people manage to merge with the AGI and reap its benefits, and others not.

However, if the self-improvement rate of the AGI is not exponential, there may be enough maneuvering time to bring it under control again. The AGI might start to disrupt the socio-economic structures [4], pushing affected groups into action. This could lead to some sort of AGI safety consortium, which includes C1, that could be dedicated to developing and deploying safety measures to bring the technology under control. Therefore, this consortium would be created out of necessity and would likely stay together to ensure AGI remains beneficial in the future. Once the AGI is under control it could theoretically lead to a scenario where a powerful and safe AGI can be (re)created transparently.

Powerful and safe AGI

The powerful and safe AGI outcome can be reached from both scenario 1 and 2 (see diagram). It is possible that some sort of powerful AGI prototype will go onto the market, and while it will not pose an existential threat, it will likely cause major societal disruptions and automation of most of the jobs. This could lead to the need for a form of a “universal basic income”, or an alternative model which enables the sharing of income and benefits of AGI among the population. For example, the general public could be able to claim their share in the new “AI economy” through mechanisms provided by an inclusive alliance (see below). Note that the role of governments as public support program providers might significantly reduce unless the governments have access to AGI alongside powerful economic players. Traditional levers the governments push to obtain resources through taxation might not be sufficient in a new AI economy.

Scenario 2 — AI race: focus on safety

In this scenario AGI is seen as a powerful tool, which will give its creator a major economic and societal advantage. It is not primarily considered here (as it is above) as an existential risk, but as a likely cause of many disruptions and shifts in power. Developers keep most research private and any alliances do not grow past superficial PR coalitions, however, a lot of work is done on AI safety. Two possible paths this scenario could take are a collaborative approach to development or a stealth one.

Collaborative approach

With various actors calling for collaboration on AGI development it is likely that some sort of consortium would develop. This could start off as an ad-hoc trust building exercise between a few players collaborating on “low stake” safety issues, but could develop into a larger international AGI co-development structure. Nowadays the way towards a positive scenario is being paved with notable initiatives including the Partnership on AI [5], IEEE working on ethically aligned design [6], the Future of Life Institute [7] and many more. In this roadmap a hypothetical organization of a global scale, where members collaborate on algorithms and safety (titled “United AI” analogous to United Nations), is used as an example. This is more likely to lead to the “Powerful and safe AGI” state described above, as all available global talent would be dedicated, and could contribute, to safety features and testing.

Stealth approach

The opposite could also happen and developers could work in stealth, still doing safety work internally, but trust between organizations would not be strong enough to foster collaborative efforts. This has the potential to go in many different paths. The roadmap focuses on what might happen if multiple AGIs with different owners emerge around the same time or if C1 has a monopoly over the technology.

Multiple AGIs

Multiple AGIs could emerge around the same time. This could be due to a “leak” in the company, other companies getting close at the same time, or if AGI is voluntarily given away by its creators.

This path also has various potentials depending on the creators’ goals. We could reach a “war of AGIs” where the different actors battle it out for absolute control. However, we could find ourselves in a situation of stability, similar to the post-WW2 world, where a separate AGI economy with multiple actors develops and begins to function. This could lead to two parallel worlds of people who have access to AGI and those who don’t, or even those who merge with AGI creating a society of AGI “gods”. This again could lead to greater inequality, or an economy of abundance, depending on the motivations of the AGI “gods” and whether they choose to share the fruits of AGI with the rest of humanity.

AGI monopoly

If C1 manages to keep AGI within its walls through team culture and security measures, it could go a number of ways. If C1 had bad intentions it could use the AGI to conquer the world, which would be similar to the “war of AGIs” (above). However, the competition is unlikely to stand a chance against such powerful technology. It could also lead to the other two end states above: if C1 decides to share the fruits of the technology with humanity, we could see an economy of abundance, and if it doesn’t, the society will likely be very unequal. However, there is another possibility explored and that is if C1 has no interest in this world and continues to operate in stealth once AGI is created. With the potential of the technology C1 could leave earth and begin to explore the universe without anyone noticing.

Scenario 3 - smooth transition from narrow AI to AGI

This scenario sees a gradual transition from narrow AI to AGI. Along the way infrastructure is built up and powershifts are slower and more controlled. We are already seeing narrow AI occupy our everyday lives throughout the economy and society with manual jobs becoming increasingly automated [8] [9]. This progression may give rise to a narrow AI safety consortium which focuses on narrow AI applications. This model of narrow AI safety / regulation could be used as a trust building space for players who will go on to develop AGI. However, actors who pursue solely AGI and choose not to develop narrow AI technologies might be left out of this scheme.

As jobs become increasingly automated, governments will need to secure more resources (through taxation or other means) to support the affected people. This gradual increase in support could lead to a universal basic income, or a similar model (as outlined above). Eventually AGI would be reached and again the end states would depend on the motivation of the creator.

What did we learn?

Although this roadmap is not a comprehensive outline of all possible scenarios it is useful to demonstrate some possibilities and give us ideas of what we should be focusing on now.

Collaboration

Looking at the roadmap it seems evident that one of the keys to avoiding a doomsday scenario, or a war of AGIs, is collaboration between key actors and the creation of some sort of AI safety consortium or even an international AI co-development structure with stronger ties between actors (“United AI”). In the first scenario we saw the creation of a consortium out of necessity after C1 lost control of the technology. However, in the other two scenarios we see examples of how a safety consortium could help control the development and avoid undesirable scenarios. A consortium that is directed towards safety, but also human well-being, could also help avoid large inequalities in the future and promote an economy of abundance. Nevertheless, identifying the right incentives to cooperate at each point in time remains one of the biggest challenges.

Universal basic income, universal basic dividend, or similar

Another theme that seems inevitable in an AI or AGI economy is a shift towards a “jobless society” where machines do the majority of jobs. A state where, due to automation, the predominant part of the world’s population loses work is something that needs to be planned for. Whether this is a shift to universal basic income, universal basic dividend [10] distributed from a social wealth fund which would invest into equities and bonds, or a similar model that will ensure the societal changes are compensated for, it needs to be gradual to avoid large scale disruptions and chaos. The above-mentioned consortium could also focus on the societal transition to this new system. Check out this post if you would like to read more on AI and the future of work.

Solving the AI race

The roadmap demonstrates implications of a technological race towards AI, and while competition is known to fuel innovation, we should be aware of the risks associated with the race and seek paths to avoid them (e.g. through increasing trust and collaboration). The topic of the AI race has been expanded in the General AI Challenge set up by GoodAI, where participants with different backgrounds from around the world have submitted their risk mitigation proposals. Proposals varied in their definition of the race as well as in their methods for mitigating the pitfalls. They included methods of self-regulation for organisations, international coordination, risk management frameworks and many more. You can find the six prize winning entries at https://www.general-ai-challenge.org/ai-race. We encourage the readers to give us feedback and build on the ideas developed in the challenge.

References

[1] Armstrong, S., Bostrom, N., & Shulman, C. (2016). Racing to the precipice: a model of artificial intelligence development. AI & SOCIETY, 31(2), 201–206.

[2] Allen, G., & Chan, T. (2017). Artificial Intelligence and National Security, Technical Report. Harvard Kennedy School, Harvard University, Boston, MA.

[3] Bostrom, N. 2017. Strategic Implications of Openness in AI Development.

Global Policy 8: 135–148.

[4] Brundage, M., Shahar, A., Clark, J., Allen, G., Flynn, C., Farquhar, S., Crootof, R., & Bryson, J. (2018). The Malicious Use of Artificial Intelligence: Forecasting, Prevention, and Mitigation.

[5] Partnership on AI. (2016). Industry Leaders Establish Partnership on AI Best Practices

[6] IEEE. (2017). IEEE Releases Ethically Aligned Design, Version 2 to show “Ethics in Action” for the Development of Autonomous and Intelligent Systems (A/IS)

[7] Tegmark, M. (2014). The Future of Technology: Benefits and Risks

[8] Havrda, M. & Millership, W. (2018). AI and work — a paradigm shift?. GoodAI blog Medium.

[9] Manyika, J., Lund, S., Chui, M., Bughin, J., Woetzel, J., Batra, P., Ko, R., and Sanghvi, S.

(2017). Jobs lost, jobs gained: What the future of work will mean for jobs, skills, and wages. Report from McKinsey Global Institute.

[10] Bruenig, M. (2017). Social Welfare Fund for America. People’s Policy Project.

Roadmapping the AI race to help ensure safe development of AGI was originally published in AI Roadmap Institute Blog on Medium, where people are continuing the conversation by highlighting and responding to this story.

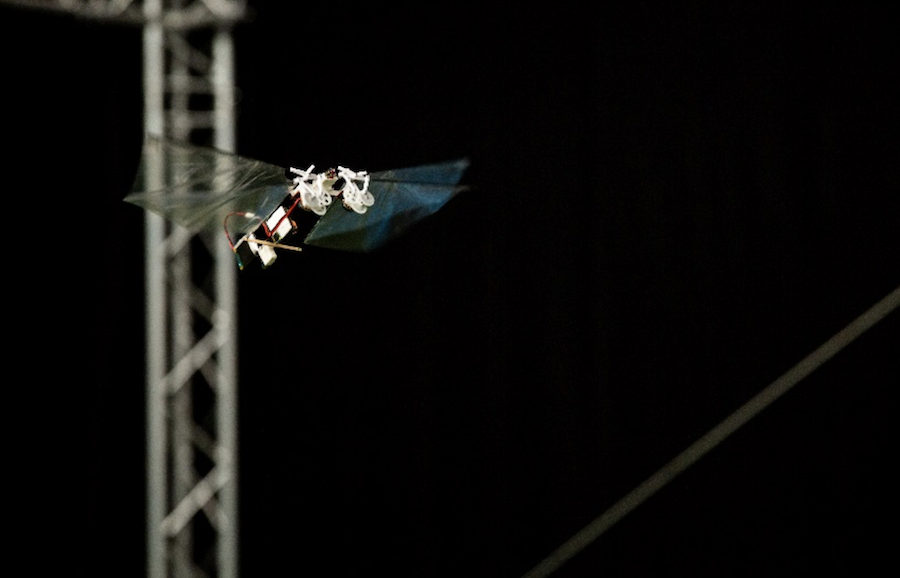

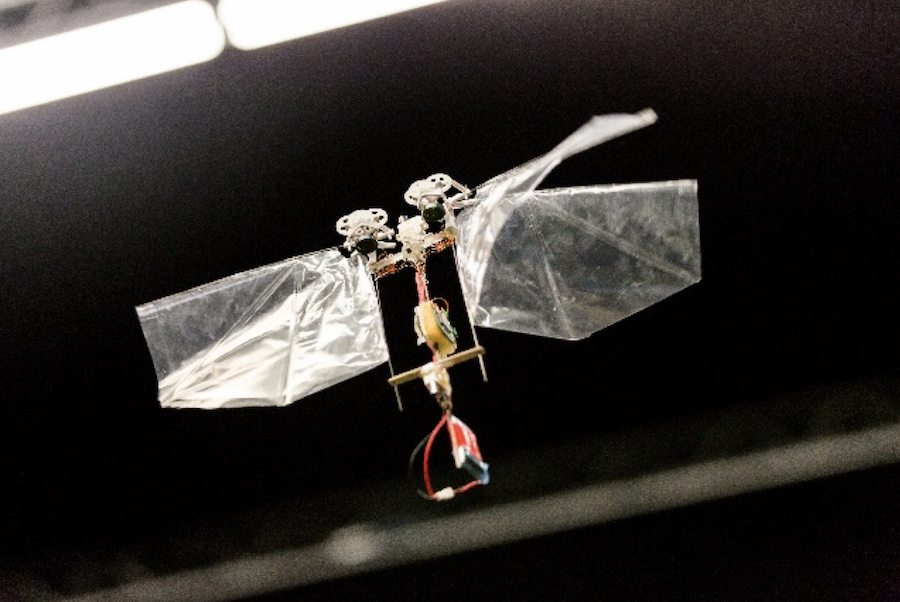

DelFly Nimble mimics the high-speed escape of fruit flies

Bio-inspired flapping wing robots hold a great potential. The promise is that they can fly very efficiently even at smaller scales, while being able to fly fast, hover, and make quick maneuvers. We now present a new flapping wing robot, the DelFly Nimble, that is so agile that it can even accurately mimic the high-speed escape maneuvers of fruit flies. In the scientific article, published in Science, we show that the robot’s motion resembles so much that of the fruit fly that it allowed us to better understand the dynamics of fruit flies during escape maneuvers. Here at Robohub, we wish to give a bit more background about the motivation and process of how we got to the final design of this robot, and what we think the future may bring.

At TU Delft, we have been working since 2005 on flapping wing robots. The first one, the DelFly I, was made by a group of students, guided by the lab staff. Already this first model, which had a wingspan of 50 cm and a weight of 21 grams, was designed to carry a camera for remote inspection. In fact, one of the defining aspects of the DelFly, the X-wing configuration, was chosen so that a camera attached to the body would not vibrate too much during flight. This configuration also really worked out well for the efficiency of flight, as the touching and parting of the wings (termed “clap-and-fling”) significantly increased lift production. DelFly I could be tele-piloted with First Person View to fly into a room, look around, and fly out again.

Since the first DelFly design, we have been scaling the DelFly down (even down to the camera-equipped, 10cm wingspan and 3 gram DelFly Micro), but we have always kept a focus on keeping a fully operational platform with a camera (see video below).

Moreover, we have made the DelFly smarter (e.g., the fully autonomous 20-gram DelFly Explorer in the video below), so that it can fly around in buildings if there is no video link to a human pilot.

However, when flying all these DelFly models in realistic real-world environments, we were often faced with the challenges of wind and wind gusts. This definitely is a challenge when flying outdoors, or from outdoors to indoors, but even a strong air conditioning could push the DelFly off its course, enough to cause trouble. The problem here is the fact that all these DelFly models steered by means of an airplane-like tail, with a rudder and elevator. When flying fast, the air would go very fast over these surfaces, providing quite some control authority, but when flying slower, most of the air would come from the flapping of the DelFly’s own wings, leading to less control authority.

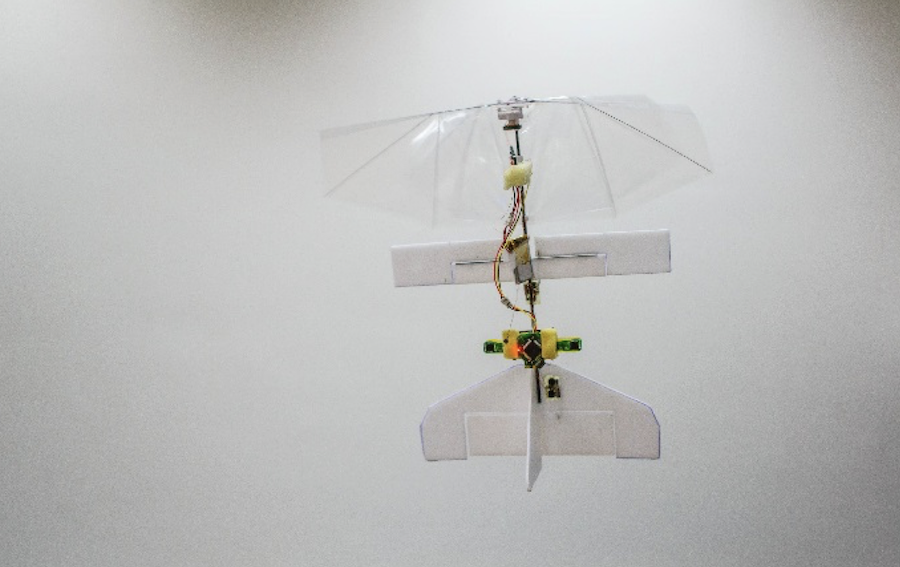

The solution to this problem is to steer more like insects do: by changing the wing motion to introduce body rotations. This allows for much higher torques, and hence much more agile behavior. Removing the stabilizing tail does introduce the need for active attitude control. Steering with the wings was first used on a flapping wing robot by AeroVironment’s Nano Hummingbird, and – with a very different mechanical design – is also used on the tiny Robobee. For the DelFly design, we have made some different choices as we will explain below.

Looking at flying animals, there are many ways how the rotations around their three orthogonal body axes can be controlled. The wing motion patterns of flying insects show large differences among various species, and the changes in these patterns inducing the body rotations often involve many parameters. However, with robots, we are limited by the currently available actuators, and the current level of technology in general. We were thus searching for a solution that would: 1) require minimal number of actuators to generate the three torques inducing the respective body rotations, and the lift force keeping the robot airborne, 2) be able to generate these torques independently, ideally by mechanically decoupled mechanisms, 3) and that would be as simple as possible, to keep the system lightweight. Moreover, we wanted to reuse as much as possible of our previous, reliable and efficient, DelFly designs.

We landed on a concept, which reuses two of the flapping wing mechanisms, each with two 14-cm wings installed only on one side. The two mechanisms, one of each side of the robot, can provide the thrust force but also roll moments, if one of the two wing pairs is driven at a higher frequency, and thus producing higher thrust force, than the other. These two mechanisms are not rigidly fixed to the body, but their relative orientation can be controlled by a simple, 3D-printed servo-actuator-driven gear mechanism. This allows to shift the flapping wings (and their thrust forces) more in front of, or behind the body, which results in a pitch moment, making the body tilt forward or backward. Finally, we have added a third servo actuator that deflects the bottoms of the wing roots asymmetrically; this tilts the thrust vectors clockwise or counter clockwise (when viewed from the top), and results in a yaw torque, making the body turn around its axis.

Compared to previous tailless designs, this solution allows production with available and established manufacturing technologies, and relatively easy assembly. Moreover, the effectiveness of the control mechanisms is very high, allowing highly agile maneuvers. Importantly, this effectiveness is rather insensitive to the position of the center of gravity, which can shift when a battery is changed or when a camera is added to the system. Thanks to this insensitivity we can even play with the position of the center of gravity, either making the DelFly more agile or more stable in flight, without losing control authority. Finally, for high-speed forward flight, the DelFly has to move its wings backwards to pitch forward; this also introduces a positive dihedral effect that helps with the stabilization in this fast flight mode.

We think that the DelFly Nimble is a great starting point to start exploring real-world applications, such as flying in greenhouses to monitor the crop or flying in warehouses to scan the stock. It can hover for over 5 minutes and when flying fast forward it has a range of a kilometer. With its onboard computer – an open source 2.8 gram Lisa S autopilot that is used for actively stabilizing the robot – we can make it execute pre-programmed behaviors such as flips or rapid turns. Towards the future, we want to investigate ways to make it smaller and smarter, but we promise not to teach it how to lay eggs on the fruit in your kitchen.

Research team

Matěj Karásek (1)

Florian Muijres (2)

Christophe De Wagter (1)

Bart Remes (1)

Guido de Croon (1)

(1) Micro Air Vehicle Laboratory, Control and Simulation, Delft University of Technology, Delft, Netherlands.

(2) Experimental Zoology Group, Wageningen University and Research, Wageningen, Netherlands.