Researchers develop car driving system that can ‘look into the future’ with smart eco mode

Self-healing materials for robotics made from ‘jelly’ and salt

Black in Robotics ‘Meet The Members’ series: Andrew Dupree

Inside of the development studios of San Francisco-based Dexterity, Inc. there is a robot arm that stands as tall as a human. It is placed between a conveyor belt and several wooden pallets, all of which are typical of most warehouse packing facilities. But this is no typical warehouse facility.

This is the location where most warehouse packing facilities would have teams of people manually picking up boxes from the conveyor belt and carefully placing them onto the pallets for wrapping and shipping, but there are no such people here. Instead, as the packages come down the belt, this robot recognizes them, picks them up, and then deposits them onto the target pallet with a gentle touch. It can do all of this on its own, and when a human does enter its vicinity, the robot knows to avoid the human’s area thanks to a “light curtain” sensor.

Andrew Dupree is one of the product managers developing technology like this at Dexterity (p.s. they are hiring!) and, in this ‘Meet the Members’ post, we will look at his journey from pure engineering and working with nonprofits in Haiti to doing product development in the bay area for several budding hardware startups.

Andrew’s trajectory

Andrew described his early childhood as that of a typical “blerd” (aka a black nerd). His father was an early adopter of things like personal computers and Andrew vividly remembers his first computer, a Gateway machine, being delivered to the house.

He spent tons of time poring over the device and creating websites with his brother using Angelfire and HTML. This passion for technology later be combined with a drive to have a social impact at the University of Maryland – College Park. The plan was to do “a Computer Engineering degree focusing on low-cost computers”, but while Andrew worked through courses like Signal Theory, he noted that something seemed to be missing from his experience.

His first attempt to find that “missing piece” was to join a laboratory at UC Berkeley for an internship at their TIER Lab. When the internship was finished and he returned to the East Coast, he remained connected to the local Information and Communications Technology for Developing Countries (ICT4D) community. It was at one of the community’s meetups that he was introduced to a nonprofit working in Haiti and “they actually knew the professor that I’d worked with in Berkeley because it’s a small scene.”

Andrew leveraged this connection to reach out to them with an offer:

I reached out to them and said “Look, I’ve done this internship and I’ve done this work. Are you hiring?”

And they were like “No.”

Then I said, “Are you sure?”

And they said “We’re sure.”

Then I asked “What if I volunteer?”

And they responded “Let’s talk.”

And thus, he had locked in an eight month experience with the nonprofit Inveneo focusing on setting up computer labs and implementing computer literacy programs in Haiti. There was only one detail that he needed to work out: Figuring out what to do with the graduate school admissions offers that had begun to come in. He began to ask around about deferring his admission for a year with surprising results.

“All of the other grad schools that I asked about deferring [said “No”, but] Stanford actually really bent over backwards to help me defer. They don’t have a proper deferral, but they [found a way] and really hooked me up.”

— Andrew

While Stanford’s graduate school offer was being worked out, he dove into the world of Haiti’s Inveneo which was filled with ups and downs. Andrew humbly summarizes his emotions with “Fixing the world is really hard. I had good days where I felt like ‘I’m really making an impact’ and I had bad days where I felt like ‘My work is doing nothing here. This is a tough challenge.’” When he eventually returned to the United States for his Master’s at Stanford, he decided to focus more on the engineering skills that he had not had the time to focus on while working at the nonprofit. In his engineering classes again, he felt like he was missing something, not accessing a part of himself that he really wanted to.

“… I ended up doing a bunch of design classes. And [specifically the] business management for engineers class, that last one was a huge eye opener for me. Because I realized we were doing case studies, and analyzing business strategies [and more]. I really enjoyed that material.”

— Andrew

Andrew did so well in the class that the professor strong-armed him into TA’ing it the following year. Curious about how he could combine his love for business management with his engineering expertise, Andrew asked this professor what careers would best mix these two worlds. “That’s easy,” the professor explained. “You become a product manager.”

So, as Andrew began his career, he sought out experiences to work with or become a product manager. After working on several important hardware engineering teams, he was able to successfully make the jump and has held the title of product manager (in some form) at multiple Silicon Valley hardware-focused tech companies.

He is currently thrilled to be a product manager at the high growth start-up Dexterity, Inc. which develops “full-stack, end-to-end systems for kitting, picking, packing, counting, sorting, palletizing, and order fulfillment.”

“… Working at a small, high-growth startup is a lot of fun … and I think that robotics in Supply Chain/Logistics is huge. It’s going to be even bigger. … I’ve worked in a bunch of different industries at this point and this is my first experience working in an industry where customers truly have a huge problem and they need you to help them solve it.”

— Andrew

In addition to his work at Dexterity, Andrew is excited to return to his passion for social impact. After reading and reflecting on his multiple experiences (both in industry and with ICT4D), he wants “to continue to think about tangibly [making] steps towards social impact and making the world a better place. I’m not sure what that looks like yet, but I’m excited to figure that out.”

Andrew’s challenges

Discovering Andrew’s inner “product manager” might have been accelerated if he had been more receptive to the idea earlier on. He recalls colleagues teasing him while at the University of Maryland with “Oh, you’re just gonna be a business manager at some point.” The culture of valuing technical expertise above all else encouraged people like him to reject the idea of becoming a business manager or leader. It’s a problem that still exists today and that Andrew would like to counter:

“I think what I would’ve internalized earlier is that there are a lot of ways to contribute in technical areas/technical disciplines [like robotics]. For example, it’s critical to understand the problem that you’re trying to solve, to define that clearly, to communicate that clearly and also to keep engineering efforts focused on an impactful outcome.”

— Andrew

Another challenge that Andrew encountered was attempting to get a Product Manager position with only engineering experience on his resumé. Realizing that he needed to convince potential recruiters of his capabilities, he:

- Showcased his understanding of hardware and business via blog posts on his website,

- Discussed relevant product management events and ideas with others on Twitter, and

- Moonlit as a product manager while also performing his current role (as a project manager)

Feel free to check out his website, where he has authored dozens of blog posts on topics ranging from circular buffers to conducting user research to understanding the options for hardware housings. Using this approach, Andrew successfully showcased an understanding of product management that won him the attention of several interesting hardware teams.

Andrew’s words of wisdom

We asked Andrew to share some of the intangible lessons he has learned through the challenges mentioned above and he had many. Some of the important ones are described below.

One of the lessons that has served Andrew well is the importance of self-help books. As he puts it: “A lot of people have been doing this `human` thing for a while. There’s probably no need to reinvent the wheel.” He specifically picks up books that are pervasive or challenge his current ideas about the world. Some examples of books that have previously landed on his reading list are:

- The 7 Habits of Highly Effective People, by Stephen R. Covey

- Winners Take All: The Elite Charade of Changing the World, by Anand Giridharadas

“You’ve got to separate out some of the nonsense, but being proactive about your personal growth … is something that I’ve been intentional about.”

— Andrew

His plan for becoming a Product Manager was one of the things that he had been intentional about and he established a strategy that was able to get him into the career of his choice!

Andrew also advises against pressuring yourself to always be in a rush, whether it be in robotics or in life.

“One of the things that’s surprised me in hindsight is that there’s a lot of time. There’s no huge rush. It feels like if you have turned twenty-six and haven’t made a certain impact, then [there’s a problem.] But looking back, I see that I’ve worked across a bunch of different industries from Academic Research to Consumer Tech. A couple of different flavors of industrial stuff. And I have had at least three or four different job functions entirely. There really doesn’t need to be a rush.”

— Andrew

More from Andrew

To see more from Andrew, please feel free to go to his website.

Also, Dexterity is growing and might need a Black roboticist like you! Reach out to Andrew on our Slack (or through his contact info above) if you’re interested in a role there!

Acknowledgements

Drafts of this article were corrected and improved by Andrew Dupree, Nosa Edoimioya, and Nailah Seale. All current errors are the fault of Kwesi Rutledge. Please reach out to him if you spot any!

Robotic cubes shapeshift in outer space

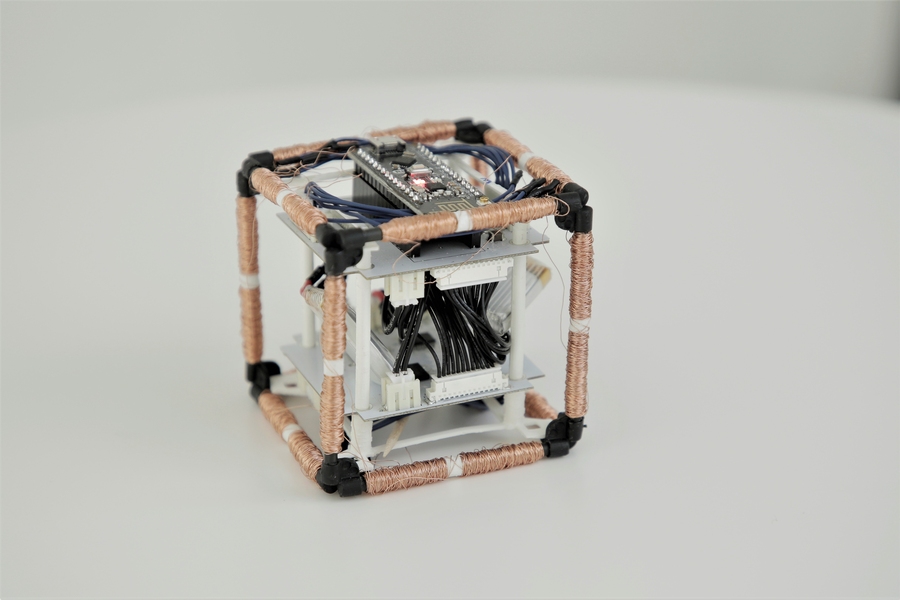

MIT PhD student Martin Nisser tests self-reconfiguring robot blocks, or ElectroVoxels, in microgravity. Photo: Steve Boxall/ZeroG

By Rachel Gordon | MIT CSAIL

If faced with the choice of sending a swarm of full-sized, distinct robots to space, or a large crew of smaller robotic modules, you might want to enlist the latter. Modular robots, like those depicted in films such as “Big Hero 6,” hold a special type of promise for their self-assembling and reconfiguring abilities. But for all of the ambitious desire for fast, reliable deployment in domains extending to space exploration, search and rescue, and shape-shifting, modular robots built to date are still a little clunky. They’re typically built from a menagerie of large, expensive motors to facilitate movement, calling for a much-needed focus on more scalable architectures — both up in quantity and down in size.

Scientists from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) called on electromagnetism — electromagnetic fields generated by the movement of electric current — to avoid the usual stuffing of bulky and expensive actuators into individual blocks. Instead, they embedded small, easily manufactured, inexpensive electromagnets into the edges of the cubes that repel and attract, allowing the robots to spin and move around each other and rapidly change shape.

The “ElectroVoxels” have a side length of about 60 millimeters, and the magnets consist of ferrite core (they look like little black tubes) wrapped with copper wire, totaling a whopping cost of just 60 cents. Inside each cube are tiny printed circuit boards and electronics that send current through the right electromagnet in the right direction.

Unlike traditional hinges that require mechanical attachments between two elements, ElectroVoxels are completely wireless, making it much easier to maintain and manufacture for a large-scale system.

ElectroVoxels are robotic cubes that can reconfigure using electromagnets. The cubes don’t need motors or propellant to move, and can operate in microgravity.

To better visualize what a bunch of blocks would look like while interacting, the scientists used a software planner that visualizes reconfigurations and computes the underlying electromagnetic assignments. A user can manipulate up to a thousand cubes with just a few clicks, or use predefined scripts that encode multiple, consecutive rotations. The system really lets the user drive the fate of the blocks, within reason — you can change the speed, highlight the magnets, and display necessary moves to avoid collisions. You can instruct the blocks to take on different shapes (like a chair to a couch, because who needs both?)

The cheap little blocks are particularly auspicious for microgravity environments, where any structure that you want to launch to orbit needs to fit inside the rocket used to launch it. After initial tests on an air table, ElextroVoxels found true weightlessness when tested in a microgravity flight, with the overall impetus of better space exploration tools like propellant-free reconfiguration or changing the inertia properties of a spacecraft.

By leveraging propellant-free actuation, for example, there’s no need to launch extra fuel for reconfiguration, which addresses many of the challenges associated with launch mass and volume. The hope, then, is that this reconfigurability method could aid myriad future space endeavors: augmentation and replacement of space structures over multiple launches, temporary structures to help with spacecraft inspection and astronaut assistance, and (future iterations) of the cubes acting as self-sorting storage containers.

“ElectroVoxels show how to engineer a fully reconfigurable system, and exposes our scientific community to the challenges that need to be tackled to have a fully functional modular robotic system in orbit,” says Dario Izzo, head of the Advanced Concepts Team at the European Space Agency. “This research demonstrates how electromagnetically actuated pivoting cubes are simple to build, operate, and maintain, enabling a flexible, modular and reconfigurable system that can serve as an inspiration to design intelligent components of future exploration missions.”

To make the blocks move, they have to follow a sequence, like little homogeneous Tetris pieces. In this case, there are three steps to the polarization sequence: launch, travel, and catch, with each phase having a traveling cube (for moving), an origin one (where the traveling cube launches), and destination (which catches the traveling cube). Users of the software can specify which cube to pivot in what direction, and the algorithm will automatically compute the sequence and address of electromagnetic assignments required to make that happen (repel, attract, or turn off).

For future work, moving from space to Earth is the natural next step for ElectroVoxels, which would require doing more detailed modeling and optimization of these electromagnets to do reconfiguration against gravity here.

“When building a large, complex structure, you don’t want to be constrained by the availability and expertise of people assembling it, the size of your transportation vehicle, or the adverse environmental conditions of the assembly site. While these axioms hold true on Earth, they compound severely for building things in space,” says MIT CSAIL PhD student Martin Nisser, the lead author on a paper about ElectroVoxels. “If you could have structures that assemble themselves from simple, homogeneous modules, you could eliminate a lot of these problems. So while the potential benefits in space are particularly great, the paradox is that the favorable dynamics provided by microgravity mean some of those problems are actually also easier to solve — in space, even tiny forces can make big things move. By applying this technology to solve real near-term problems in space, we can hopefully incubate the technology for future use on earth too.”

Nisser wrote the paper alongside Leon Cheng and Yashaswini Makaram of MIT CSAIL; Ryo Suzuki, assistant professor of computer science at the University of Calgary; and MIT Professor Stefanie Mueller. They will present the work at the 2022 International Conference on Robotics and Automation. The work was supported, in part, by The MIT Space Exploration Initiative.

A method to automatically generate radar-camera datasets for deep learning applications

Recent Innovations in the Field of Security Robotics Show Potential

Team develops fingertip sensitivity for robots

Tim Chung: DARPA Subterranean Challenge | Sense Think Act Podcast #14

In this episode, Audrow Nash speaks to Tim Chung, Program Manager in the Tactical Technology Office at the Defense Advanced Research Projects Agency (DARPA), on the DARPA Subterranean (SubT) Challenge. The SubT Challenge is a robotics challenge that aims to develop innovative technologies that would augment operations underground. In this conversation, they talk about the motivation of the SubT Challenge, its systems (hardware) and virtual (simulation) challenges, how the resulting technology has been shared with the world, on benchmarking the robotics behaviors in simulation, on the challenge of scoping the SubT Challenge, and on building the final environment for the systems challenge.

Episode Links

- Download the episode

- The SubT Challenge’s Website

- Tim’s LinkedIn

- DARPAtv’s YouTube Channel

- SubT’s Repository on OSRF

Podcast info