Industrial robotics

By Anastasiia Nestrogaeva (Junior Consultant at the International Projects Team, Civitta)

Robotics4EU is a 3-years-long EU-funded project which advocates for a wider adoption for AI-based robots in 4 sectors: healthcare, inspection and maintenance of infrastructure, agri-food, and agile production. Thus, Robotics4EU raises awareness about non-technological aspects in robotics through delivering a series of workshops to involve the research community, industry representatives and citizens.

The workshop “Robots: Friends and Enemies? Social impact of Robotics in Inspection and Maintenance” which took place on the 26th of January, 2022 tackled the problem of interactions between robots and humans. How to evaluate the real impact of robotics on our society? How to decide if robots are hazardous and may complicate human lives? To what extent does society accept rapidly progressing robotic technologies? All these issues were brought up during the fruitful discussion at the workshop. Around 30 people attended the workshop, with 65% of them belonging to the research community and 10% to industry representatives. About 25% comprised the general public. The participants represented 23 different countries, mostly European ones.

How to access trustworthy AI?

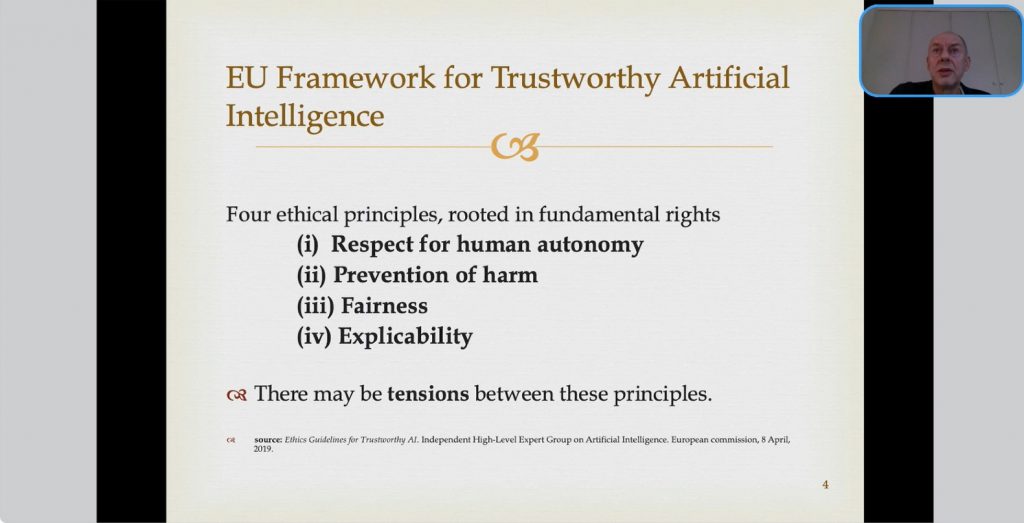

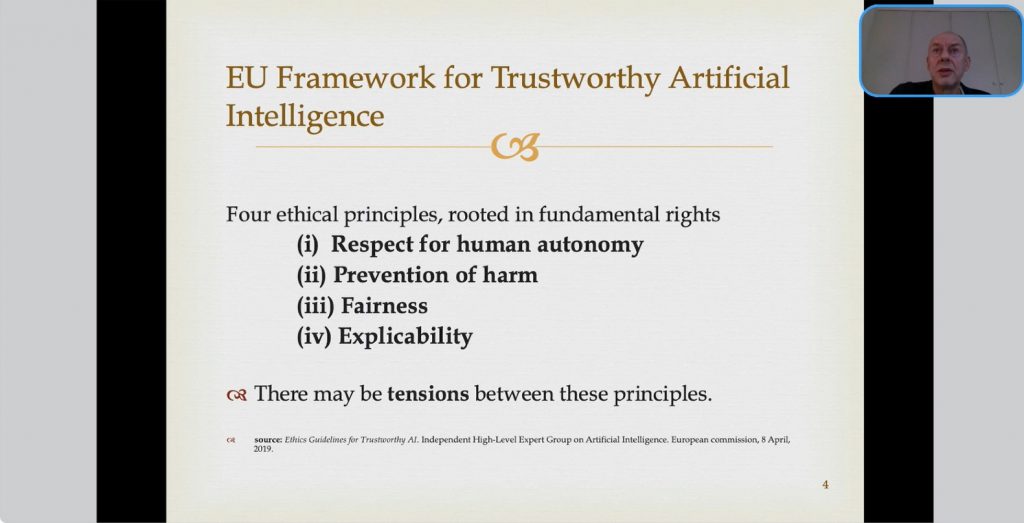

The workshop initiated with the presentation of the project and a brainwriting session at better involvement of participants into discussion, then four speakers shared their expertise with the participants. The first speaker was Roberto Zicari who is an affiliated professor at the Arcada University of Applied Sciences in Helsinki and an adjunct professor at the Seoul National University. Also, Roberto leads a team of international experts who defined an assessment process for Trustworthy AI, called Z-Inspection®. The speaker enlisted 4 main fundamental principles which lie down in the EU Framework: respect for human autonomy, prevention of harm, fairness, and explicability. Also, there are 7 main requirements of the EU towards the trustworthy AI: accountability; societal and environmental well-being; diversity, non-discrimination and fairness; transparency, privacy and data governance, technical robustness and safety.

Despite the existing requirements, the EU Framework does not take into account the evolving nature of the technologies and is not contextualised according to various domain peculiarities. That is why, as Roberto stressed, Z-inspection used a holistic approach and created the orchestration process which helps teams of experts access the ethical, legal, technical and domain specific implications for the use of AI products or services. This process can be employed during the whole AI lifecycle and uses socio-technical scenarios to identify issues. Then, the team of experts map to trustworthy AI (onto the ethical categories established by the EU´s Guidelines for Trustworthy AI), execute and resolve (give recommendations to stakeholders).

Embracing our future digital colleagues

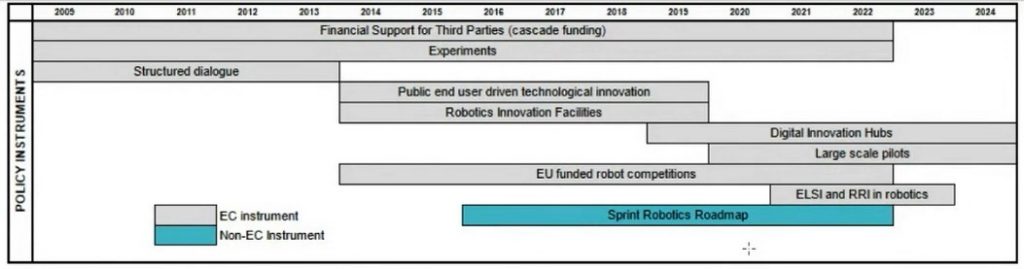

Second speech was delivered by Maarit Sandelin who works as the European Network Manager in SPRINT Robotics focusing on Robotic Innovation. Maarit explained that SPRINT Robotics is an industry-driven initiative that promotes the development, availability and application of Inspection & Maintenance Robotics around the world. There are 4 focuses which include safety improvement, cost avoidance and reduction, environmental performance improvement, and general performance improvement. Maarit explained that SPRINT Robotics is an industry-driven initiative that promotes the development, availability and application of Inspection & Maintenance Robotics around the world. There are 4 focuses which include safety improvement, cost avoidance and reduction, environmental performance improvement, and general performance improvement.

Maarit stressed that COVID-19 definitely has been increasing the interest of business in robotic solutions. A total of 88% of businesses worldwide plan on adopting robotic automation into their infrastructure to increase efficiency and safety. Also, there will be a 12% increase in shipment of robots worldwide and collaborative robots (cobots) will constitute 34% of all robot sales by 2025. The speaker noticed that many dangerous inspection and maintenance activities can be done by robots and efficiency is reached mainly through the preparation stage. However, the main barriers for integrating the robotics solution into operations are regulations. In some countries, the usage of robotics is not allowed by the legislature or its interpretations which, in turn, cause issues for service and technical providers. Maarit strongly believes that the policy changes are needed to contribute to the adoption of robots.

There are also other barriers of a wide-spread adoption. Companies would need to reduce the workforce, to modify the location where a company operates, or even to modify the whole value chain. Also, the skills gaps in the local labour markets is also seen as a potential risk which would require proper training. Talking about displacement of jobs, Maarit stated that it will continue and 85 million jobs will be displaced by 2025, but 97 jobs may appear due to new division of work between humans and machines. Maarit said there is a need to show employees that robotics is not black-and-one, and reskilling may help to save a job.

BugWright2 Project

The second half of the workshop featured the BugWright2 Project which does autonomous robotic inspection and maintenance on ship hulls and storage tanks. Alberto Ortiz Rodrigez, who works as a Professor at University of the Balearic Islands, gave the information about the goals and main activities of the project. The project has the 5-steps approach: multi robot task allocation; mission planning; autonomous inspection; data post processing and actionable data generation; and maintenance which include hull cleaning, augmented reality, defect marking. Alberto showed a few examples of robots which perform different tasks. Lasly, the speaker stressed the importance of the project, enlisting 4 potential impacts. First, it demonstrates how the automated multi-robot technologies can be deployed into a large-scale industrial problem. Second, such technologies lead to cost efficiency: fuel saving, lower service costs, no immobilisation costs. Third, it brings a positive environmental impact, as it makes the ships and tanks safer, contributes to lower fuel consumption and smaller need for antifouling. Lastly, these autonomous inspections are regulated by the World Maritime Organisation (UN).

Human-Robot-Collaboration: perspectives from work and organisational psychology

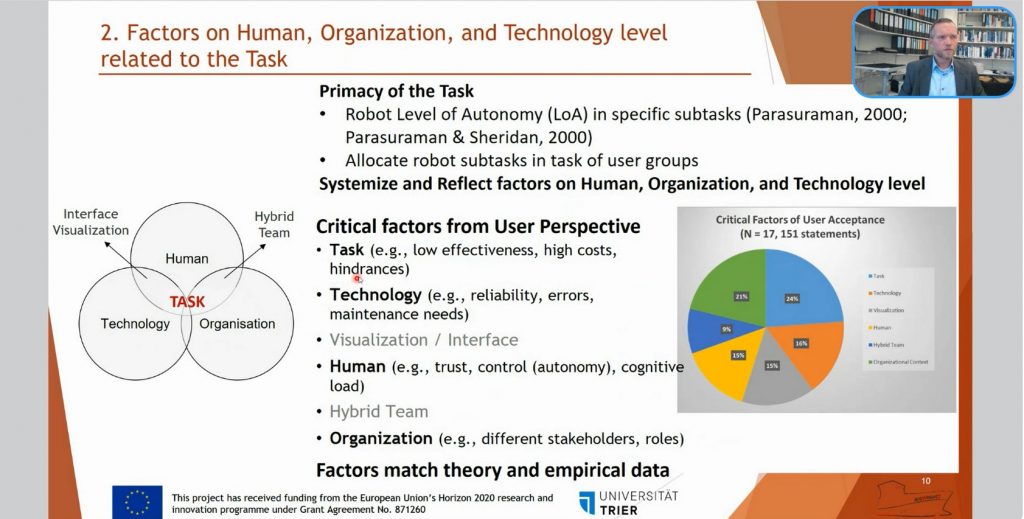

The last speech was delivered by Thomas Ellwart who works as a Professor at the University of Trier. He touched the topic of the interactions between robots and humans. While bringing up the main topic of the workshop “Are robots friends or enemies?”, the speaker noticed that there is a need to define a criteria of terms “friends” and “enemies” or, in other words, criteria of functional / dysfunctional human-robot-interactions (HRC). For psychologists, the main important issue to evaluate among the HRC is a very specific task of employees on the ship. Thomas is convinced that there is a need to reflect abstract models of robotic solutions from on-site user perspective. Talking about criteria of functional HRC, they should:

- Facilitate the proper execution of the tasks

- Protect health and increase safety

- Promote individual well-being

- Develop skills and human abilities

- Avoid under/overload demands, isolated works, task hindrances, etc.

However, a high robot autonomy causes some dysfunctional effects of high robot autonomy such as exclusion of humans for safety reasons, reduced possibilities to apply and train skills, responsibilities to react in case of failures or disturbances, and low quality residual tasks. This way, humans are excluded from the task performance, but they are still in charge of system malfunctioning. This way, a high autonomy creates the high interdependence between human tasks and robots – if a robot breaks, a task is under danger, which may postpone the accomplishment of these tasks. Also, Thomas stressed that acceptance is also a double-faced matter: overtrust is as dangerous as mistrust.

However, a high robot autonomy causes some dysfunctional effects of high robot autonomy such as exclusion of humans for safety reasons, reduced possibilities to apply and train skills, responsibilities to react in case of failures or disturbances, and low quality residual tasks. This way, humans are excluded from the task performance, but they are still in charge of system malfunctioning. This way, a high autonomy creates the high interdependence between human tasks and robots – if a robot breaks, a task is under danger, which may postpone the accomplishment of these tasks. Also, Thomas stressed that acceptance is also a double-faced matter: overtrust is as dangerous as mistrust.

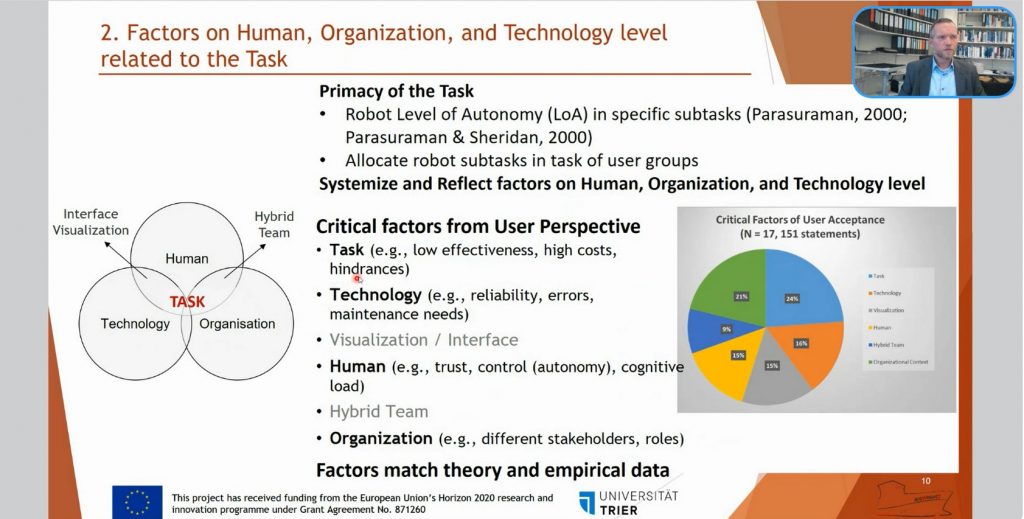

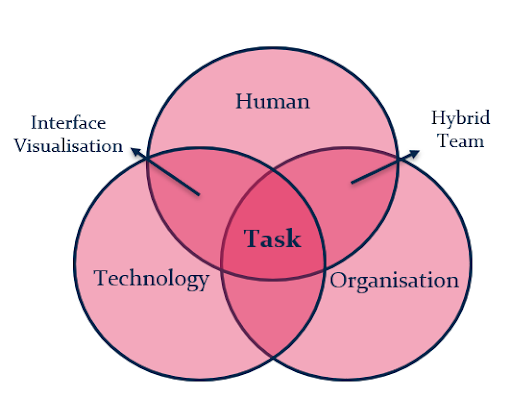

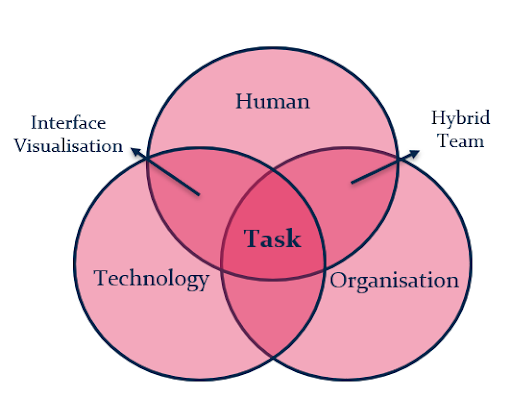

To reflect all the criteria, the psychologists look at specific tasks, asking what level of autonomy the robot has and what subtasks it performs. Is it making decisions or just monitoring and implementing action? Thus, from the user perspective, there are critical factors which should be taken into account:

- Taks (low effectiveness, high costs, hindrances)

- Technology (reliability, accuracy, maintenance needs)

- Human (e.g. trust, control, cognitive load: how many robots can be overlooked by a human)

- Organisation (e.g. different stakeholders, roles)

As one the aims of Robotics4EU is to develop the Responsible Robotics Assessment Model, a main coordinator of the project, Anneli Roose, talked about social readiness of robots. Thus, in order to determine this, it is important to figure out to what extent a robot meets a) ethical values, b) socio-economic needs, c) data issues, d) education and management issues, e) legal concerns. It does not cover any legal or regulatory requirements. The foundation to build the Robotics4EU Assessment Model is the Societal Readiness Levels, while the used tools are surveys, interviews, debates, workshops, and stakeholder forums involving the robotics research community, policy makers, and citizens.

Panel discussion

Lastly, the workshop finished with the panel discussion which brought up very controversial topics.

How to design a self-assessment model or self-assessment tool in a way it would be valid in 2-3 years. Is it possible or even relevant?

Thomas Ellwart stressed that this is a quite difficult question, as it requires to involve the users and the market. Another matter is whether the automated system will be sustainable and adaptable to the changing environment and reliable over the time which is actually a question to the developers and engineers. Roberto Zicari notices that the Maturity Assessment Model should be domain specific, as a robot assisting the healthcare is very different from the robot replacing mine workers. Thus, it is quite difficult to transfer knowledge obtained in the healthcare sector to the Inspection and Maintenance. He stressed that it would be very interesting to create an interdisciplinary working group focused on several domains and try to assess societal readiness level.

Are the regulatory barriers significant? Are these barriers in the EU regulations or/and national regulations?

Thomas Ellwart states that there are 2 difficult matters: safety and data protection, which come together if we are talking about the regulation on AI. Roberto Zicari mentioned that the EU proposed the first AI Regulation Act, aimed at regulating any AI-based systems and solutions which is based on the risk assessment approach. This proposed act looks at AI mainly as a software, opposite to the classical definition. However, which exact composition of hardware and AI poses high risk and low risk? Thus, Roberto stressed that there is a need for discussions among researchers, law community and industry experts. Some participants also noticed that the regulatory framework would need to be adapted to the cultural differences all around the world.

Upcoming Workshop

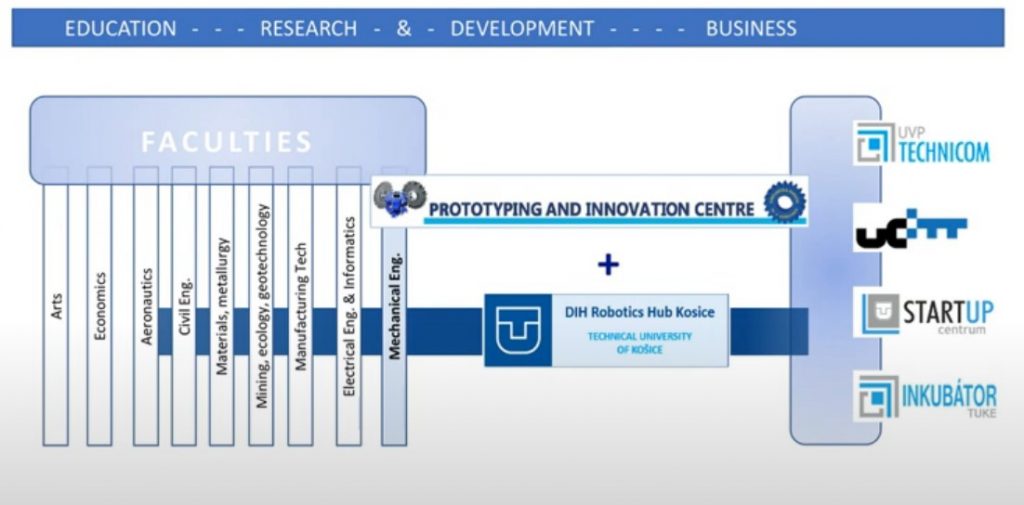

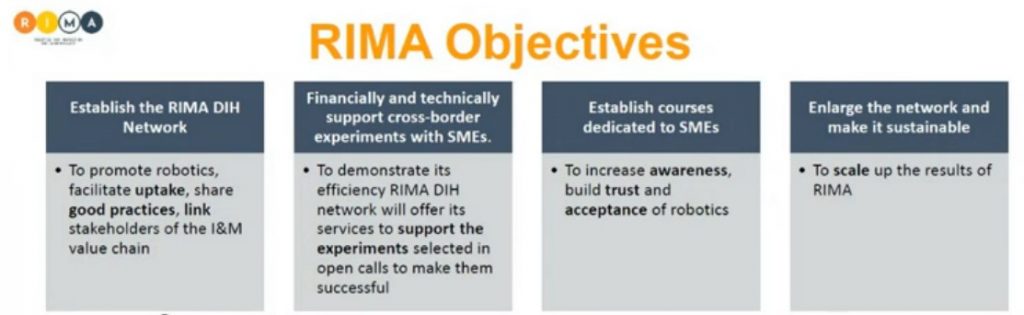

The upcoming workshop on the 23rd of February 2022, 11-14 CET “Boosting Innovations and Maximising Societal Impact. Role of Digital Innovation Hubs (DIHs) in Robotics for Inspection & Maintenance”. We will look at digital innovation hubs as a way to connect institutions and SMEs, helping to close the knowledge gap of non-technological issues of robotics in Inspection & Maintenance. We will focus on opportunities which bring SMEs and tech startups together and how they can potentially boost their innovations in the respected area. The workshop will feature representatives from digital innovation hubs, as well as industry experts.

However, a high robot autonomy causes some dysfunctional effects of high robot autonomy such as exclusion of humans for safety reasons, reduced possibilities to apply and train skills, responsibilities to react in case of failures or disturbances, and low quality residual tasks. This way, humans are excluded from the task performance, but they are still in charge of system malfunctioning. This way, a high autonomy creates the high interdependence between human tasks and robots – if a robot breaks, a task is under danger, which may postpone the accomplishment of these tasks. Also, Thomas stressed that acceptance is also a double-faced matter: overtrust is as dangerous as mistrust.

However, a high robot autonomy causes some dysfunctional effects of high robot autonomy such as exclusion of humans for safety reasons, reduced possibilities to apply and train skills, responsibilities to react in case of failures or disturbances, and low quality residual tasks. This way, humans are excluded from the task performance, but they are still in charge of system malfunctioning. This way, a high autonomy creates the high interdependence between human tasks and robots – if a robot breaks, a task is under danger, which may postpone the accomplishment of these tasks. Also, Thomas stressed that acceptance is also a double-faced matter: overtrust is as dangerous as mistrust.