Multi-robotic fabrication methods can strongly increase the potential of robotic fabrication for architectural applications through the definition of cooperative assembly tasks. As such, the objective of this research is to investigate and develop methods and techniques for the multi-robotic assembly of discrete elements into geometrically complex space frame structures.

This endeavour implies the definition of an integrative digital design method that leads to fabrication and structure informed assemblies that can be automatically built up into custom configurations. The research is being conducted at Gramazio Kohler Research as part of the interdisciplinary research program of the Swiss National Centre of Competence in Research (NCCR) Digital Fabrication. It started in September 2014 by Stefana Parascho and currently includes collaborations with Augusto Gandía and Thomas Kohlhammer.

Spatial Structures

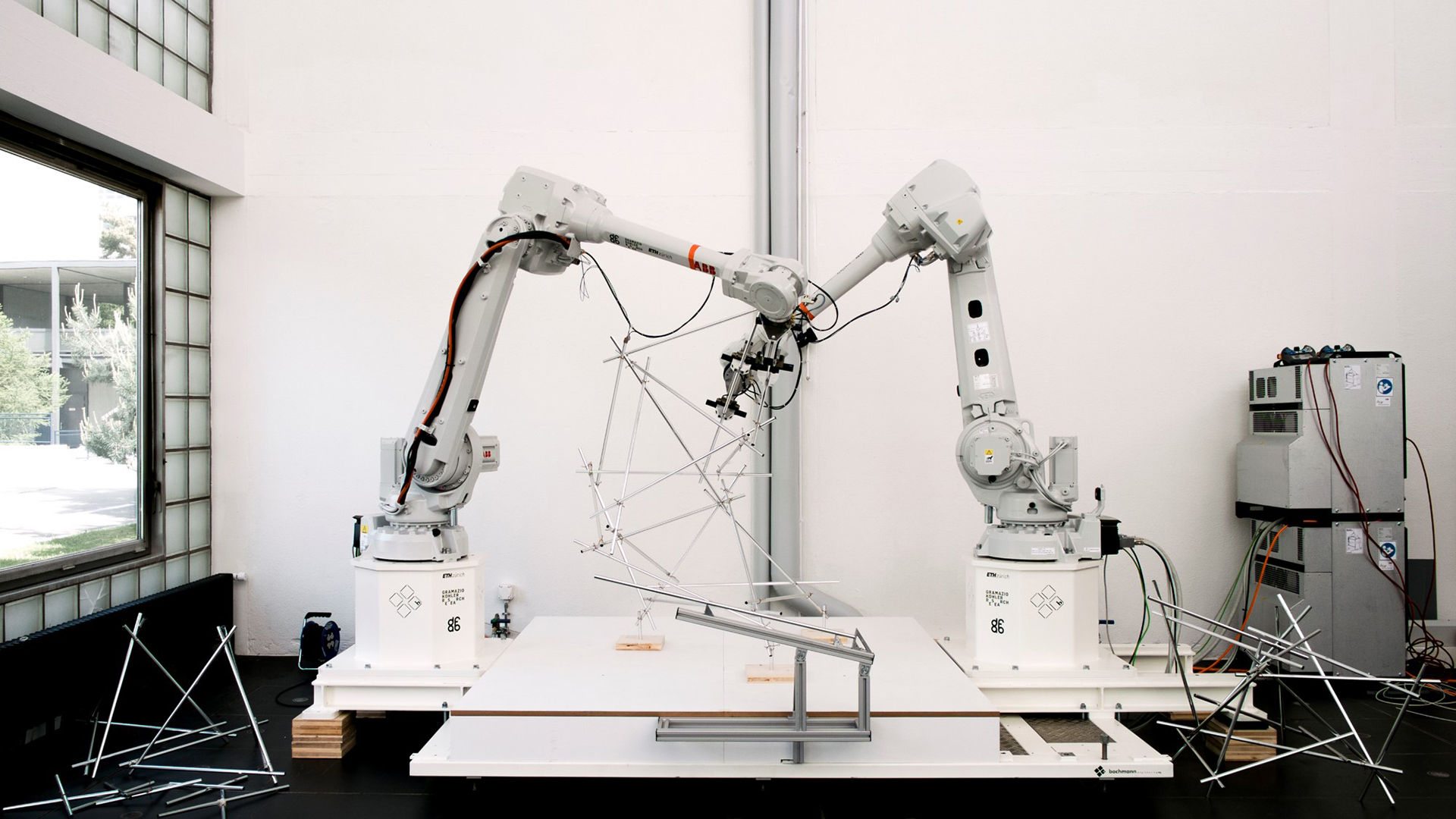

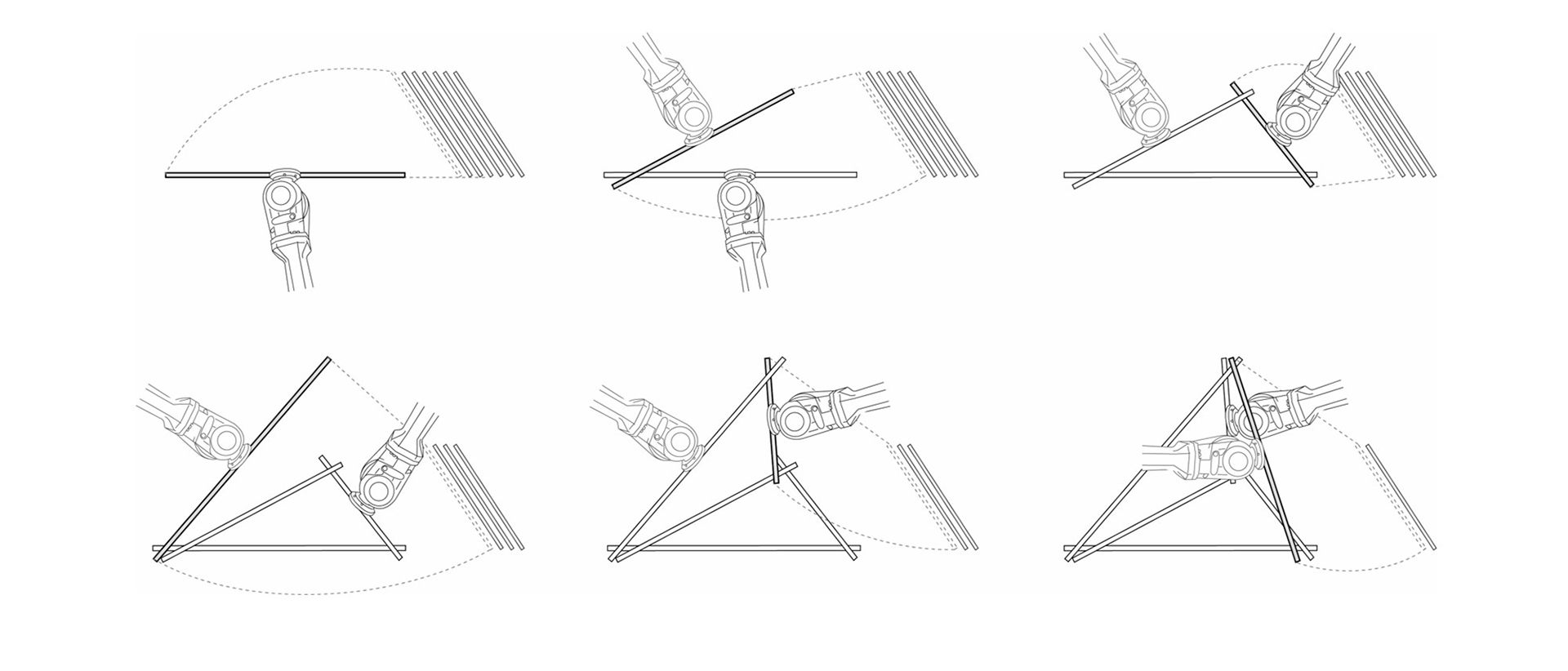

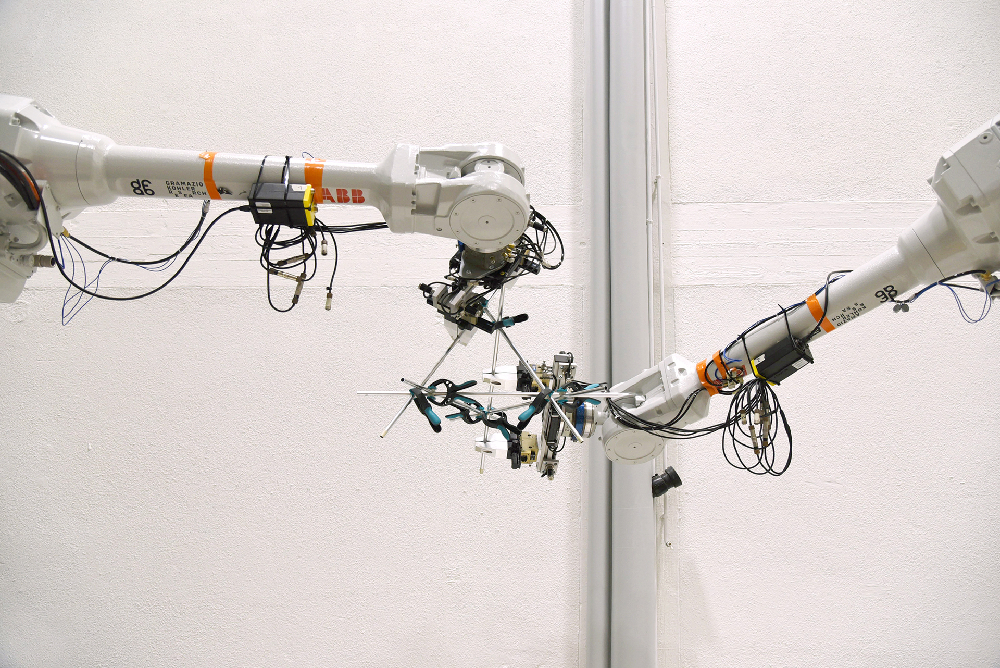

Space frames structures developed during the industrial revolution as efficient systems for large-span constructions, but quickly reached a limitation of their variability through the necessity of standardisation as well as complex connection detailing. Through the development of a multi-robotic assembly method as well as an integrated joining system, irregular space frame geometries become buildable, enhancing existing typologies through their potential for variability and efficient material use. The use of robotic fabrication techniques and the avoidance of pre-fabricated, rigid connections lead to a system that relies not only on digital planning and manufacturing but includes digital assembly as an addition to the digital chain. A process of robotic build-up of triangulated structures was developed, based on the alternating placement of rods. This way, one robot always serves as a support for the already built structure while the other assembles a new element (Figure 02). As a result, the built structures do not require any additional support structures and are constantly stabilised by the robots.

Integrative Design Methods

Traditional architectural design methods commonly follow a top-down strategy in which both construction and fabrication are subordinated to a previously predefined geometry. In an integrative design approach, the fabrication, structural performance and given boundary constraints can simultaneously function as design drivers, allowing for a much higher flexibility and performance of the system. As such, the presented research focuses on the development of a design strategy in which various factors, such as constraints and characteristics of the multi-robotic fabrication process, are included in the geometric definition process of the structures.

Multi-robotic fabrication

The use of multiple robots for the assembly of discrete element structures opens up potentials for the build-up of complex, stable, three-dimensional constructions. At the same time, the process introduces various challenges such as the necessity for collision avoidance strategies between multiple robots and respective robotic path planning. In order to generate buildable structures, the design process needs to integrate the robots’ constraints, such as robot reach and kinematic behaviour, and at the same time process data from robotic simulation in order to foresee the robots’ precise movements. Through the collaboration with Augusto Gandía from Gramazio Kohler Research a strategy for implementing robotic simulation into a CAD environment and for generating collision free trajectories for multi-robotic applications was developed.

If you liked this article, you may also be interested in:

- Rock Print: A zero-waste 3D-printed structure made only of rock and thread

- New Master of Advanced Studies (MAS) in architecture and digital fabrication at ETHZ

- Architectural robots: The shape of the robots that will shape your home

- Short video: In situ Fabricator a “game-changer” in construction methods

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.