#335: Autonomous Aircraft by Xwing, with Maxime Gariel

Abate talks to Maxime Gariel, CTO of Xwing about the autonomous flight technology they are developing.

At Xwing, they retrofit traditional aircraft to include multiple sensors such as cameras, lidar, and radar. Using sensor fusion algorithms, they create an exceptionally accurate model of the environment. This model of the environment and advanced path planning and control algorithms allow the plane to autonomously navigate in the airport, take off, fly to a destination, and land, all without a person on board.

Maxime Gariel

Maxime Gariel is the CTO of Xwing, a San Francisco based startup whose mission is to dramatically increase human mobility using fully autonomous aerial vehicles. Xwing is developing a Detect-And-Avoid system for unmanned and remotely piloted vehicles. Maxime is a pilot but he is passionate about making airplanes fly themselves.

Maxime joined Xwing from Rockwell Collins where he was a Principal GNC Engineer. He worked on autonomous aircraft projects including DARPA Gremlins and the AgustaWestland SW4 Solo autonomous helicopter. Before becoming Chief Engineer of the SW4 Solo’s flight control system, he was in charge of the system architecture, redundancy, and safety for the project.

Before Rockwell Collins, he worked on ADS-B based conflict detection as a postdoc at MIT and on autoland systems for airliners at Thales. Maxime earned his MS and PhD in Aerospace Engineering from Georgia Tech and his BS from ISAE-Supaéro (France).

Links

- Download mp3 (21.2 MB)

- Subscribe to Robohub using iTunes, RSS, or Spotify

- Support us on Patreon

Robot with rapid motor adaptation able to traverse multiple types of terrain

ITRI introduces AI-based high density shuttle rack system

The Industrial Technology Research Institute (ITRI) in Taiwan has introduced the AI-Based High Density Shuttle Rack System (SRS). This smart storage system, which operates without manpower in thousands of square meters of space, uses Artificial Intelligence to make warehousing decisions.

ITRI’s system is an all-in-one pick, pack and fulfillment system for high volume e-commerce. Current capacities allow up to 1.25 miles of track for robotic shuttles, with vertical lifts for movement up and down as many as 14 floors of storage capacity. Inventory replenishment and picking is enabled by real-time positioning and tracking with low-latency 5G infrastructure.

A proprietary integrated management software system forms the backbone of operations, with big data crunching enabling a constant flow of warehousing decisions driven by changing demand forecasts, including peak volumes produced by holiday seasons or special campaigns.

When new goods enter the warehouse, the system automatically makes volumetric measurements, measuring the weight and size of each item and storing that information in the cloud. It then factors in the popularity of each item, including short term promotions, campaigns, holidays, weather, and other factors, before sending each item to an optimal storage location for maximum efficiency on an ongoing basis. The system also takes into account common combinations (e.g. toothbrush & toothpaste) to further optimize efficiency. It is able to further improve its performance as it learns from order histories as well.

Economic Affairs (MOEA) Taiwan

Once orders are ready to be shipped, the SRS determines the best path for items to be retrieved from the shelves, and items are timed to arrive simultaneously to the packing area in order to minimize packing time. SRS also assists packing workers by guiding them to each item using light beams and numbers.

The Director of the Service System Technology Center of ITRI -Chen Hui Juan- explains that the SRS leads to improvements in three areas: decision-making accuracy, utilization of space, and speed of shipping.

With AI algorithms and data analysis, as well as information on seasons, weather, holidays, and other factors, the SRS can accurately predict orders that will be arriving in the warehouse, and determine optimal plans for these orders to be stored and shipped.

The combination of optimized placement and shipping for products as well as vertically capable systems allows goods to be delivered 60% faster than traditional warehousing solutions.

While not in widespread use, ITRI’s technology has already been piloted in a Yahoo facility in Taiwan, with HCT Logistics running warehouse operation control and iAmech manufacturing the automation equipment.

Plans are in place for several Taiwanese companies to install SRS in various warehouses in Southeast Asia.

Meanwhile, Chen and the rest of the team at ITRI are working to boost performance of the SRS. Dynamic shuttle tracking and positioning technology have been integrated to improve the precision of automation control. Chen reveals that in the future, ITRI plans to integrate robotic arms into the loading process for boxes ready to be shipped out, continue to improve efficiency, and position Taiwan’s smart logistics solutions to compete on a global stage.

Robotics: The Era of AI and Autonomy

Bristol Robotics Lab Virtual Conference 2021 (with videos)

The Bristol Robotics Laboratory (BRL) hosted their first virtual conference last Wednesday, the 30th of June. With over 50 talks, the conference was a gathering of top robotics researchers, business leaders and PhD/post-doctoral students showcasing cutting-edge research. In their four dedicated tracks, speakers covered a wide range of topics such as unmanned aerial vehicles, soft robotics, assistive technologies, human-robot interaction, robot safety & ethics, or swarm robotics, among others. Moreover, there were two panels discussing the future of robotics, and smart automation & startups.

In case you missed the conference, or you would like to re-watch it, BRL has made all the talks available through their dedicated YouTube channel. For your comfort, you’ll find all the videos in the playlist below. To see the details of each track or talk, you can access their programme navigator. Speakers’ email addresses are also available for you to contact them directly.

Would you like to go even deeper? You can now discover where the previous research takes place through their virtual walkthrough. Enjoy!

Smart Micro Factories for the Watchmaking Industry

Better gripping with intelligent picking robots

A universal approach to tailoring soft robots

PHYSFRAME: a system to type check physical frames of reference for robotic systems

Zimmer Group Supports Vischer & Bolli Robot Cell With Kuka Robots and a Bespoke Gripper

Russian Yandex to launch delivery robots in US

Softbank Robotics Europe cutting workforce 40% in shake-up

Softbank Robotics Europe, the group behind two of the more recognizable robots, is laying off 40% of its workforce. On July 7, the developer of the famous Nao and Pepper robots will reduce its Paris-based workforce that had 330 employees as of March 2021.

The Robot Report confirmed this news, which was first reported by French media outlet Le Journal du Net. Softbank Robotics Europe lost \$38 million in its fiscal 2019-2020 year and more than \$119 million over the last three years, according to Le Journal du Net.

Despite their worldwide fame, the Nao and Pepper robots never achieved financial success. Most of the 27,000 Nao and Pepper robots were sold in Japan, which is more accepting of humanoid robots than Europe, the United States and other parts of the world. While selling that many robots is certainly an achievement, price and capabilities were often issues, especially for Pepper, which costs \$30,000 in the U.S.

A Softbank Robotics Europe employee, who wished to remain anonymous, told The Robot Report “the market for Nao and Pepper is smaller than we expected.” The source added that it is “not sustainable to have this many workers in Paris based on the economic issues we are facing.”

Softbank Robotics Europe was formed after parent company Softbank acquired Aldebaran Robotics for \$100 million about a decade ago.

Softbank Robotics Europe sent this public statement to The Robot Report:

“Since 2012 SoftBank Robotics Group, a subsidiary of SoftBank, has invested in Humanoid Robotics and intends to keep Pepper & NAO robots business moving forward.

“In the light of the pandemic and economic slowdown, SoftBank Robotics Europe is considering a significant workforce optimization plan. Our EMEA HQ located in Paris is home to about 330 employees, as of March 2021.

“In this difficult time, we want to thank all our employees for their efforts in creating the best humanoids on the planet, and will make the best efforts to ensure fair departure decisions with labor representatives and local consultation bodies in France. The current round of job cuts should be completed by the end of 2021.

“The restructuring project has as one of its objectives to continue to provide product sales, services support and maintenance for Pepper and NAO robots.

“We also want to thank our customers, partners and suppliers for their trust in our Pepper & NAO products.

“SoftBank Robotics Europe will continue to make significant investments in next-generation robots to serve our customers and partners.”

Downplaying Nao & Pepper going forward

While this next information isn’t surprising, it is confirmation from a Softbank insider. The source said both Softbank Robotics Europe and Softbank Robotics America won’t be focusing on Nao and Pepper as much going forward.

“There will be less investment in emotional humanoids, and more focus on commercial products such as Whiz,” the source said. The Whiz autonomous floor cleaning robot first went on sale in early 2019 as sales of Pepper lagged.

This is part of a larger shift in strategy for Softbank’s robotics efforts. Softbank Robotics America, for example, recently announced that Nao and Pepper will be available in the U.S. exclusively through San Francisco-based RobotLAB, a company that has focused on educational robots for years. While other media outlets have referred to this as Softbank continuing to expand, it’s actually the reverse. The company is divesting from its direct channel.

Parent company Softbank will maintain the IP for both Nao and Pepper, but it’s looking to outsource much of the sales, service, and support work for these robots as they don’t generate significant revenue. The source told The Robot Report deals similar to the RobotLAB partnership are being explored for Nao and Pepper in other parts of the world.

“Pepper launched in 2014, but Whiz is our flagship robot now,” the source said. “Pepper will remain an icon in robotics, but more business efforts will be put into Whiz going forward.”

It’s been clear for a while that Nao and Pepper weren’t going to be a major part of Softbank’s robotics strategy going forward. In January 2021, for example, Softbank Group announced that Softbank Robotics will jointly develop robots with Japanese electronics maker Iris Ohyama. The joint venture, called Iris Robotics, highlighted two products that are evolutions of existing products. The first product is a new take on Softbank’s Whiz cleaning robot called the “Whiz i Iris Edition.” The second product is an updated version of Bear Robotics’ flagship robot, Servi.

As we pointed out at the time Iris Robotics was announced, neither Nao or Pepper appeared to be part of the deal. Now we know why.

Softbank has made other changes to its robotics strategy, most notably offloading 80% of its ownership stake in Boston Dynamics to Hyundai for \$880 million. It also paid \$2.8 billion for a 40% ownership stake in AutoStore, a leading developer of automated storage and retrieval systems (AS/RS). The logistics market is booming automation-wise, and now Softbank is tied up with a major player. AutoStore currently has a global blue-chip customer base with more than 600 installations and 20,000 robots across 35 countries.

Softbank also recently partnered with Bear Robotics on serving and bussing robots. Founded in 2017, Bear Robotics’ robots operate in restaurants, corporate campuses, ghost kitchens, senior care facilities, and casinos across North America, Asia, and Europe. Softbank is an investor in Bear Robotics.

This article was first published in The Robot Report.

MCRI Webcast Series – Robotics Roundtable

Play RoC-Ex: Robotic Cave Explorer and unearth the truth about what happened in cave system #0393

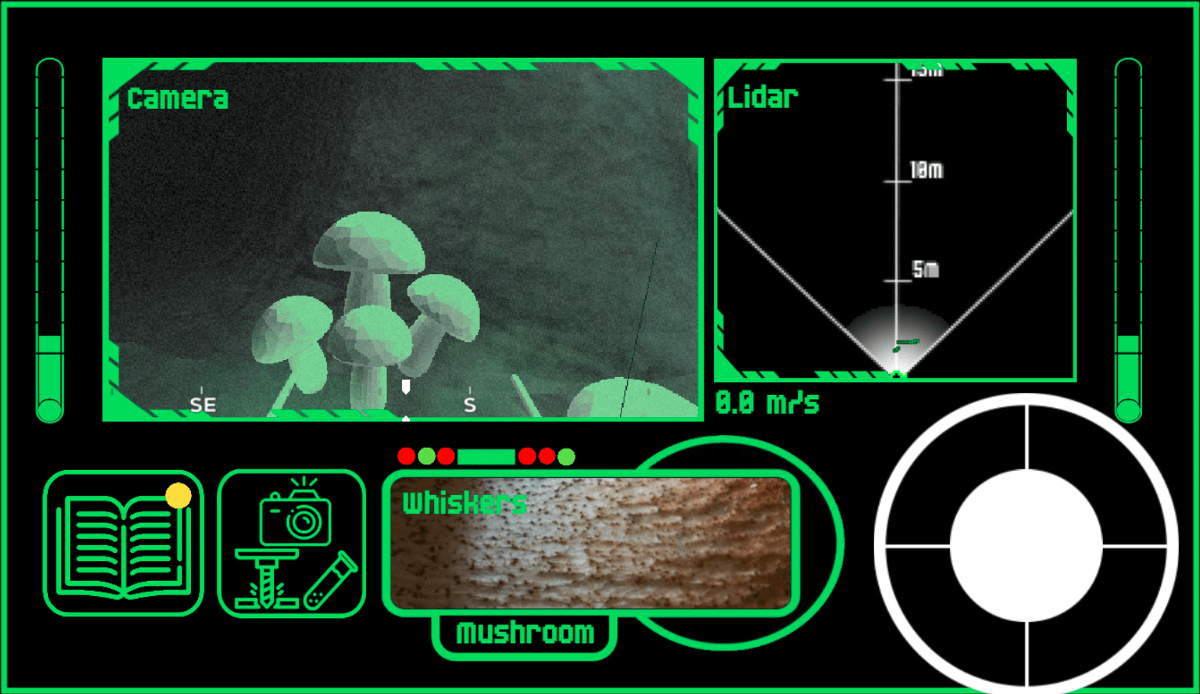

Dive into the experience of piloting a robotic scout through what appears to be an ancient cave system leading down to the centre of the Earth. With the help of advanced sensors, guide your robot explorer along dark tunnels and caverns, avoiding obstacles, collecting relics of aeons past and, hopefully, discover what happened to its predecessor.

Mickey Li, Julian Hird, G. Miles, Valentina Lo Gatto, Alex Smith and WeiJie Wong (most from the FARSCOPE CDT programme of the University of Bristol and the University of the West of England) have created this educational game as part of the UKRAS festival of Robotics 2021. The game has been designed to teach you about how sensors work, how they are used in reality and perhaps give a glimpse into the mind of the robot. With luck, this game can show how exciting it can be to work in robotics.

As the authors suggest, you can check out the DARPA Subterranean Challenge (video) (website) (not affiliated) for an example of the real life version of this game.

The game is hosted on this website. The site is secured and no data is collected when playing the game (apart from if you decide to fill in the anonymous feedback form). The source code for the game is available open source here on Github. Enjoy!