Robotic Washdown in Food-Handling Environments

Combined approach finds best direct trajectory for robot path generation

Robots Continue to Drive Innovation in Modern Transportation

#IROS2020 Real Roboticist focus series #3: Radhika Nagpal (Enjoying the Ride)

Today we continue with our series on IEEE/RSJ IROS 2020 (International Conference on Intelligent Robots and Systems) original series Real Roboticist. This time you’ll meet Radhika Nagpal, who is a Fred Kavli Professor of Computer Science at the Wyss Institute for Biologically Inspired Engineering from Harvard University.

Did you know Rhadika directed the research that led to the creation of the Kilobots, the first open-source, low-cost robots that were specifically designed for large scale experiments with hundreds and thousands of them? You can watch this example or this other one if you’re curious. If you’d like to know more about Rhadika and her achievements, challenges and what she would tell her younger self, below is the whole interview. Enjoy!

Fish fins are teaching us the secret to flexible robots and new shape-changing materials

By Francois Barthelat

The big idea

Segmented hinges in the long, thin bones of fish fins are critical to the incredible mechanical properties of fins, and this design could inspire improved underwater propulsion systems, new robotic materials and even new aircraft designs.

Francois Barthelat, CC BY-ND

Fish fins are not simple membranes that fish flap right and left for propulsion. They probably represent one of the most elegant ways to interact with water. Fins are flexible enough to morph into a wide variety of shapes, yet they are stiff enough to push water without collapsing.

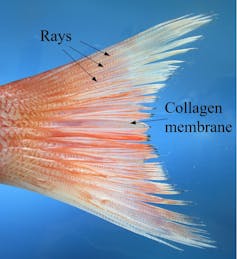

The secret is in the structure: Most fish have rays – long, bony spikes that stiffen the thin membranes of collagen that make up their fins. Each of these rays is made of two stiff rows of small bone segments surrounding a softer inner layer. Biologists have long known that fish can change the shape of their fins using muscles and tendons that push or pull on the base of each ray, but very little research has been done looking specifically at the mechanical benefits of the segmented structure.

A pufferfish uses its small but efficient fins to swim against, and maneuver in, a strong current.

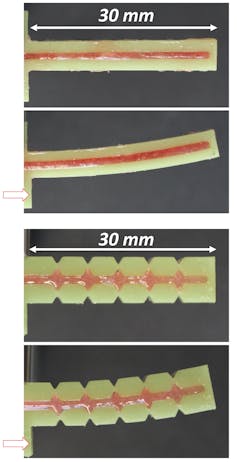

To study the mechanical properties of segmented rays, my colleagues and I used theoretical models and 3D-printed fins to compare segmented rays with rays made of a non-segmented flexible material.

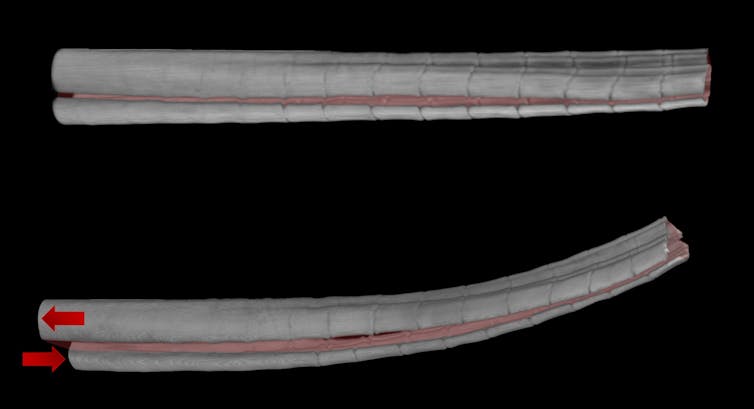

We showed that the numerous small, bony segments act as hinge points, making it easy to flex the two bony rows in the ray side to side. This flexibility allows the muscles and tendons at the base of rays to morph a fin using minimal amounts of force. Meanwhile, the hinge design makes it hard to deform the ray along its length. This prevents fins from collapsing when they are subjected to the pressure of water during swimming. In our 3D-printed rays, the segmented designs were four times easier to morph than continuous designs while maintaining the same stiffness.

Francois Barthelat, CC BY-ND

Why it matters

Morphing materials – materials whose shape can be changed – come in two varieties. Some are very flexible – like hydrogels – but these materials collapse easily when you subject them to external forces. Morphing materials can also be very stiff – like some aerospace composites – but it takes a lot of force to make small changes in their shape.

Francois Barthelat, CC BY-ND

The segmented structure design of fish fins overcomes this functional trade-off by being highly flexible as well as strong. Materials based on this design could be used in underwater propulsion and improve the agility and speed of fish-inspired submarines. They could also be incredibly valuable in soft robotics and allow tools to change into a wide variety of shapes while still being able to grasp objects with a lot of force. Segmented ray designs could even benefit the aerospace field. Morphing wings that could radically change their geometry, yet carry large aerodynamic forces, could revolutionize the way aircraft take off, maneuver and land.

What still isn’t known

While this research goes a long way in explaining how fish fins work, the mechanics at play when fish fins are bent far from their normal positions are still a bit of a mystery. Collagen tends to get stiffer the more deformed it gets, and my colleagues and I suspect that this stiffening response – together with how collagen fibers are oriented within fish fins – improves the mechanical performance of the fins when they are highly deformed.

What’s next

I am fascinated by the biomechanics of natural fish fins, but my ultimate goal is to develop new materials and devices that are inspired by their mechanical properties. My colleagues and I are currently developing proof-of-concept materials that we hope will convince a broader range of engineers in academia and the private sector that fish fin-inspired designs can provide improved performance for a variety of applications.

![]()

Francois Barthelat does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

This article appeared in The Conversation.

Here’s How Automated Packaging Gives Your E-commerce Business a Competitive Edge

Elon Musk says Tesla’s robot will make physical work a ‘choice’

Tokyo robot cafe offers new spin on disability inclusion

Lesson from a robot swarm: Change group behavior by talking one-on-one rather than getting on a soapbox

Variance and Volume Advantageously Combined One of a Kind in Series

First steerable catheter developed for brain surgery

Magnets could offer better control of prosthetic limbs

#IROS2020 Plenary and Keynote talks focus series #3: Anya Petrovskaya & I-Ming Chen

In this new release of our series showcasing the plenary and keynote talks from the IEEE/RSJ IROS2020 (International Conference on Intelligent Robots and Systems) you’ll meet Dr. Anya Petrovskaya (Stanford University), talking about driverless vehicles and field robots, and Prof. I-Ming Chen (Nanyang Technological University), whose talk is about food handling robots.

|

|

Dr. Anya Petrovskaya – A Journey through Autonomy Topical Area: Driverless Vehicles and Field Robots Bio: Dr. Anna Petrovskaya is a scientist and entrepreneur with decades of experience in the field of AI, autonomy, and 3D computer vision. Most recently, Anna built a 3D mapping startup that was acquired by Mobileye/Intel, where she became Head of LiDAR AI. She completed her Doctorate degree in Computer Science at Stanford University in 2011, where she focused on Artificial Intelligence and Robotics. In 2012, her thesis was named among the winners of the IEEE Intelligent Transportation Systems Society Best PhD Thesis Award. Anna was part of the core team that built the Stanford autonomous car Junior, which was a precursor to the Waymo/Google autonomous car. She has served as an Associate Editor for International Conference on Robotics and Automation (ICRA) since 2011. Based on her expertise, Anna has been invited to co-author chapters for the Handbook of Intelligent Vehicles and the 2nd edition of the Handbook of Robotics |

|

|

Prof. I-Ming Chen – Automation of Food Handling: From Item-Picking to Food-Picking Topical Area: Food Handling Robotics Bio: I-Ming Chen received the B.S. degree from National Taiwan University in 1986, and M.S. and Ph.D. degrees from California Institute of Technology, Pasadena, CA in 1989 and 1994 respectively. He is currently Professor in the School of Mechanical and Aerospace Engineering of Nanyang Technological University (NTU) in Singapore, and Editor-in-chief of IEEE/ASME Transactions on Mechatronics. He is Director of Robotics Research Centre in NTU from 2013 to 2017, and is also a member of the Robotics Task Force 2014 under the National Research Foundation which is responsible for Singapore’s strategic R&D plan in future robotics. Professor Chen is Fellow of Singapore Academy of Engineering, Fellow of IEEE and Fellow of ASME, General Chairman of 2017 IEEE International Conference on Robotics and Automation (ICRA 2017) in Singapore. His research interests are in logistics and construction robots, wearable devices, human-robot interaction and industrial automation. He is also CEO of Transforma Robotics Pte Ltd developing robots for construction industry and CTO of Hand Plus Robotics Pte Ltd developing robotics and AI solutions for logistics and manufacturing industry. |