Special drone collects environmental DNA from trees

An imitation-relaxation reinforcement learning framework for four-legged robot locomotion

Flexible feeding for a smarter production line

A robot able to ‘smell’ using a biological sensor

How Remote On/Off Benefits Automation Applications

New robots in Europe can be workers’ best friends

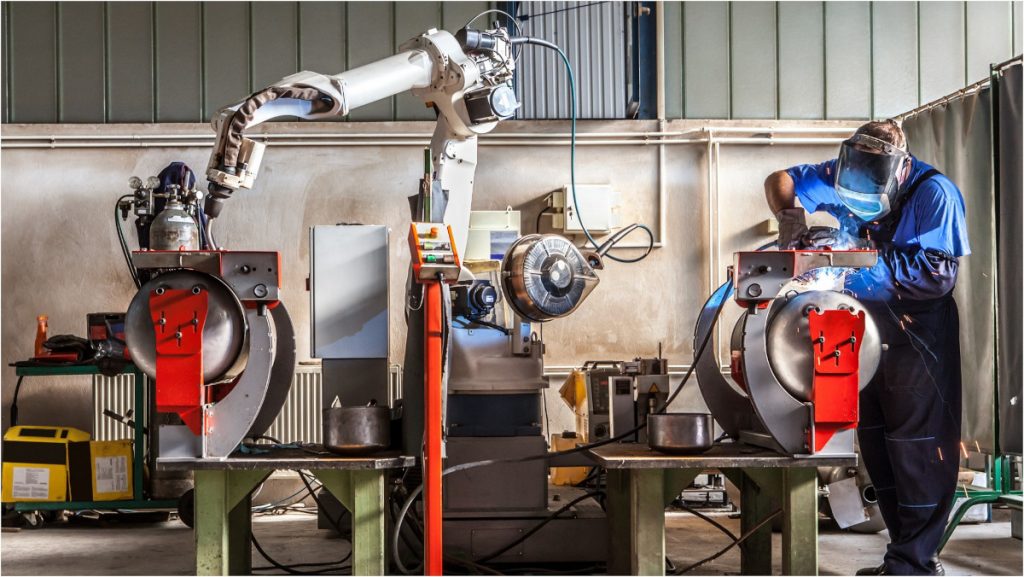

Researchers are ushering in a new way of thinking about robots in the workplace based on the idea of robots and workers as teammates rather than competitors. © BigBlueStudio, Shutterstock

For decades, the arrival of robots in the workplace has been a source of public anxiety over fears that they will replace workers and create unemployment.

Now that more sophisticated and humanoid robots are actually emerging, the picture is changing, with some seeing robots as promising teammates rather than unwelcome competitors.

‘Cobot’ colleagues

Take Italian industrial-automation company Comau. It has developed a robot that can collaborate with – and enhance the safety of – workers in strict cleanroom settings in the pharmaceutical, cosmetics, electronics, food and beverage industries. The innovation is known as a “collaborative robot”, or “cobot”.

Comau’s arm-like cobot, which is designed for handling and assembly tasks, can automatically switch from an industrial to a slower speed when a person enters the work area. This new feature allows one robot to be used instead of two, maximising productivity and protecting workers.

‘It has advanced things by allowing a dual mode of operation,’ said Dr Sotiris Makris, a roboticist at the University of Patras in Greece. ‘You can either use it as a conventional robot or, when it is in collaborative mode, the worker can grab it and move it around as an assisting device.’

Makris was coordinator of the just-completed EU-funded SHERLOCK project, which explored new methods for safely combining human and robot capabilities from what it regarded as an often overlooked research angle: psychological and social well-being.

Creative and inclusive

Robotics can help society by carrying out repetitive, tedious tasks, freeing up workers to engage in more creative activities. And robotic technologies that can collaborate effectively with workers could make workplaces more inclusive, such as by aiding people with disabilities.

“There is increasing competition around the globe, with new advances in robotics.”

– Dr Sotiris Makris, SHERLOCK

These opportunities are important to seize as the structure and the age profile of the European workforce changes. For example, the proportion of 55-to-64-year-olds increased from 12.5% of the EU’s employees in 2009 to 19% in 2021.

Alongside the social dimension, there is also economic benefit from greater industrial efficiency, showing that neither necessarily needs to come at the expense of the other.

‘There is increasing competition around the globe, with new advances in robotics,’ said Makris. ‘That is calling for actions and continuous improvement in Europe.’

Makris cites the humanoid robots being developed by Elon Musk-led car manufacturer Tesla. Wearable robotics, bionic limbs and exoskeleton suits are also being developed that promise to enhance people’s capabilities in the workplace.

Still, the rapidly advancing wave of robotics poses big challenges when it comes to ensuring they are effectively integrated into the workplace and that people’s individual needs are met when working with them.

Case for SHERLOCK

SHERLOCK also examined the potential for smart exoskeletons to support workers in carrying and handling heavy parts at places such as workshops, warehouses or assembly sites. Wearable sensors and AI were used to monitor and track human movements.

With this feedback, the idea is that the exoskeleton can then adapt to the needs of the specific task while helping workers retain an ergonomic posture to avoid injury.

‘Using sensors to collect data from how the exoskeleton performs allowed us to see and better understand the human condition,’ said Dr Makris. ‘This allowed us to have prototypes on how exoskeletons need to be further redesigned and developed in the future, depending on different user profiles and different countries.’

SHERLOCK, which has just ended after four years, brought together 18 European organisations in multiple countries from Greece to Italy and the UK working on different areas of robotics.

The range of participants enabled the project to harness a wide variety of perspectives, which Dr Makris said was also beneficial in the light of differing national rules on integrating robotics technology.

As a result of the interaction of these robotic systems with people, the software is advanced enough to give direction to ‘future developments on the types of features to have and how the workplace should be designed,’ said Dr Makris.

Old hands, new tools

Another EU-funded project that ended this year, CO-ADAPT, used cobots to help older people navigate the digitalised workplace.

“You find interesting differences in how much the machine and how much the person should do.”

– Prof Giulio Jacucci, CO-ADAPT

The project team developed a cobot-equipped adaptive workstation to aid people in assembly tasks, such as making a phone, car or toy – or, indeed, combining any set of individual components into a finished product during manufacturing. The station can adapt workbench height and lighting to a person’s physical characteristics and visual abilities. It also includes features like eye-tracking glasses to gather information on mental workload.

That brings more insight into what all kinds of people need, said Professor Giulio Jacucci, coordinator of CO-ADAPT and a computer scientist at the University of Helsinki in Finland.

‘You find interesting differences in how much the machine and how much the person should do, as well as how much the machine should try to give guidance and how,’ Jacucci said. ‘This is important work that goes down to the nuts and bolts of making this work.’

Still, cobot-equipped workplaces that can fully tap into and respond to people’s mental states in real-life settings could still be a number of years away, he said.

‘It’s so complex because there’s the whole mechanical part, plus trying to understand people’s status from their psychophysiological states,’ said Prof Jacucci.

Meanwhile, because new technologies can be used in much simpler ways to improve the workplace, CO-ADAPT also explored digitalisation more broadly.

Smart shifts

One area was software that enables ‘smart-shift scheduling’, which arranges duty periods for workers based on their personal circumstances. The approach has been shown to reduce sick leave, stress and sleep disorders among social welfare and health care workers.

‘It’s a fantastic example of how workability improves because we use evidence-based knowledge of how to have well-being-informed schedules,’ said Prof Jacucci.

Focusing on the individual is key to the future of well-integrated digital tools and robotics, he said.

‘Let’s say you have to collaborate with some robot in an assembly task,’ he said. ‘The question is: should the robot be aware of my cognitive and other abilities? And how should we divide the task between the two?’

The basic message from the project is that plenty of room exists to improve and broaden working environments.

‘It shows how much untapped potential there is,’ said Prof Jacucci.

This article was originally published in Horizon, the EU Research and Innovation magazine.

Research in this article was funded by the EU. If you liked this article, please consider sharing it on social media.

Artificial intelligence to help prevent illegal construction

Universal Robots Predicts 2023 Automation Trends Helping Manufacturers Meet New-Year Goals

Using Moroccan tea tray mathematics to turn robots into skilled waiters

New hydrogel actuator allows soft robots to move over rough terrain

Interview with Hae-Won Park, Seungwoo Hong and Yong Um about MARVEL, a robot that can climb on various inclined steel surfaces

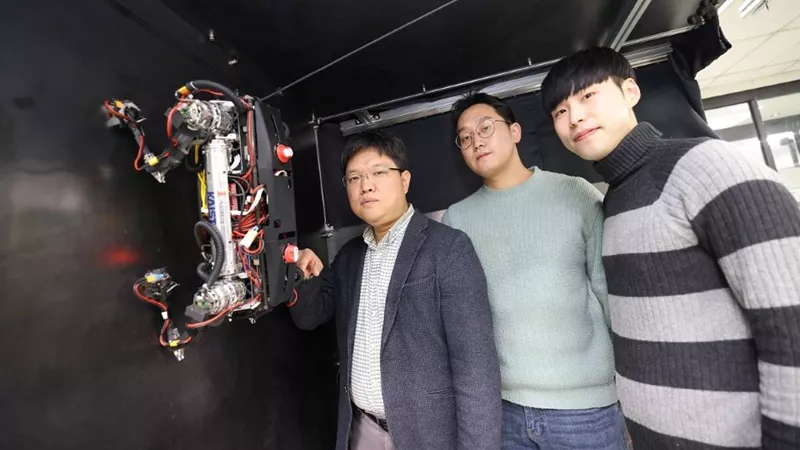

Prof. Hae-Won Park (left), Ph.D. Student Yong Um (centre), Ph.D. Student Seungwoo Hong (right). Credits: KAIST

We had the chance to interview Hae-Won Park, Seungwoo Hong and Yong Um, authors of the paper “Agile and versatile climbing on ferromagnetic surfaces with a quadrupedal robot”, recently published in Science Robotics.

What is the topic of the research in your paper?

The main topic of our work is that the robot we have developed can move agilely, not only on flat ground but also on vertical walls and ceilings made of ferromagnetic materials. Also, it has the ability to perform dexterous maneuvers such as crossing gaps, overcoming obstacles, and transitioning upon corners.

Could you tell us about the implications of your research and why it is an interesting area for study?

Such agile and dexterous locomotion capabilities will be able to expand the robot’s operational workspace and approach places that are difficult or dangerous for human operators to access directly. For example, inspection and welding operations in heavy industries such as shipbuilding, steel bridges, and storage tanks.

Could you explain your methodology? What were your main findings?

Our magnet foot can switch the on/off state in a short period of time (5 ms) and in an energy-efficient way, thanks to the novel geometry design of EPM. At the same time, the magnet foot can provide large holding forces in both shear and normal directions due to the MRE footpad. Also, our actuators can provide balanced speed/torque characteristics, high-bandwidth torque control capability, and the ability to mediate high impulsive force. To control vertical and inverted locomotion as well as various versatile motions, we have utilized a control framework (model predictive control) that can generate reliable and robust reaction forces to track desired body motions in 3D space while preventing slippage or tipping-over occurs. We found that all the elements mentioned earlier are imperative to perform dynamic maneuvers against gravity.

What further work are you planning in this area?

So far, the robot is able to move on smooth surfaces with moderate curvature. To enable the robot to move on irregularly shaped surfaces, we are working on designing a compliantly-integrated multiple miniaturized EPMs with MRE footpads that can increase the effective contact area to provide robust adhesion. Also, a vision system with high-level navigation algorithms will be included to enable the robot to move autonomously in the near future.

About the authors

|

Hae-Won Park received the B.S. and M.S. degrees from Yonsei University, Seoul, South Korea, in 2005 and 2007, respectively, and the Ph.D. degree from the University of Michigan, Ann Arbor, MI, USA, in 2012, all in mechanical engineering. He is an Associate Professor of mechanical engineering with the Korea Advanced Institute of Science and Technology, Daejeon, South Korea. His research interests include the intersection of control, dynamics, and mechanical design of robotic systems, with special emphasis on legged locomotion robots. Dr. Park is the recipient of the 2018 National Science Foundation (NSF) CAREER Award and NSF most prestigious awards in support of early-career faculty. |

|

Seungwoo Hong received the B.S. degree from Shanghai Jiao Tong University, Shanghai, China, in July 2014, and the M.S. degree from Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Korea, in August 2017, all in mechanical engineering. He is currently a Ph.D. candidate with the Department of Mechanical Engineering, KAIST, Daejeon, Korea. His current research interests include model-based optimization, motion planning and control of legged robotic systems. |

|

Yong Um received the B.S. degree in mechanical engineering from the Korea Advanced Institute of Science and Technology, Daejeon, South Korea, in 2020. He is currently working toward the Ph.D. degree in mechanical engineering in Korea Advanced Institute of Science and Technology. His research interests include mechanical system and magnetic device design for legged robot. |

CES unveiled 2023 all access with Brian Tong (+ interviews & keynotes)

CES Unveiled was jam packed with the latest and greatest tech from companies from all over the world. Get a behind-the-scenes look with Brian Tong at the innovations we saw.