3PL’s New Rack Supported Work Platforms Optimized for Autonomous Mobile Robots (AMRs)

How computer simulation will accelerate development of human-interactive ‘smart robots’

An open-source and low-cost robotic arm for online education

Controlling 6-Axis Hexapod Micro-Robots via EtherCAT®

Women in Robotics Update: Robin Murphy, Ayanna Howard

Introducing the fifth post in our new series of Women in Robotics Updates, featuring Robin Murphy and Ayanna Howard from our first “25 women in robotics you need to know about” list in 2013. These women give unstintingly of their time, creating robots that improve the quality of life, advancing research, inspiring and supporting students, and sharing their passion for engineering with the world.

Ayanna Howard says “I think as engineers we have an amazing power, where we can take people’s wishes and convert them into reality”

And Robin Murphy agrees, “My job is so incredibly fulfilling, it’s about the science and technology and the way it could be used for societal good, that’s a big deal to me,”

|

Robin Murphy

Raytheon Professor at Texas A&M University | Director of Humanitarian Robotics and AI Laboratory

Robin Murphy (featured in 2013), is the Raytheon Professor of Computer Science and Engineering in Texas A & M and Director of the non-profit Humanitarian Robotics and AI Laboratory, (formerly known as Center for Robot-Assisted Search and Rescue (CRASAR). She is a distinguished Disaster Roboticist pioneering the advancement of AI and mobile robotics in unstructured and extreme environments. At CRASAR, she has been actively supplying her rescue robot since 9/11 in 2001 and has now participated in more than 30 disasters which include building collapses, earthquakes, floods, hurricanes, marine mass casualty events, nuclear accidents, tsunamis, underground mine explosions, and volcanic eruptions, in five different countries. And she has developed and taught classes in robotics for emergency response and public safety for over 1,000 members of 30 agencies from seven countries. Murphy was named as one of the top ’30 Most Innovative Women Professors Alive Today’ in 2016 and the Engineering Faculty Fellow for Innovation in High-Impact Learning Experiences. She is also the recipient of the Eugene L. Lawler Award in 2014 for Humanitarian Contributions within Computer Science and Informatics. She has more than 400 publications and 17000 citations, 4 books (Introduction to AI Robotics, Disaster Robotics, and Robotics Through Science-Fiction Vols 1 and 2). In her Robotics Through Science-Fiction books, Murphy explains what real robotics and AI can and can’t do alongside classic robot stories from Isaac Asimov, Brian Aldiss, Philip K. Dick and Vernor Vinge. Murphy is also the chair of Robotics for Infectious Diseases, a non-profit organization which uses robotics and technology in over 20 countries for public health, public safety, and continuity of work and life. She has been tracking the wide range of work that robots have been pioneering in COVID19 as described in her recent article in The Conversation, “Robots are playing many roles in the coronavirus crisis – and offering lessons for future disaster”. “My job is so incredibly fulfilling, it’s about the science and technology and the way it could be used for societal good, that’s a big deal to me,” says Murphy in CNN’s the Great Big story in 2018. And Murphy’s TED talk from 2015 “These robots come to the rescue after a disaster” has more than 1 million views. |

|

Ayanna Howard

Professor and Chair of School of Interactive Computing at Georgia Tech | Director of the Human-Automation Systems Lab (HumAnS)

Ayanna Howard (featured 2014), is currently the Chair of the School of Interactive Computing in the College of Computing at the Georgia Institute of Technology and is on the Board of Directors for Autodesk. She is also the founder and director of the Human-Automation Systems Lab (HumAnS) where she and her team study and develop techniques to enhance the autonomous capabilities of intelligent systems in different areas such as Human-Robot Interaction, Assistive Robotics, Education and Robotics, Robot Learning, Human-Robot Trust, and Space and Field Robotics. In 2021, Howard will take up the position of Dean of Engineering at The Ohio State University. Her contributions to robotics has been recognized many times since 2013! She received an A. Richard Newton Educator ABIE Award in 2014 from the Anita Borg Institute. In 2015, she was listed in The Root 100 website, as one of the most prestigious African American achievers, and recognized by Business Insider as one of the ’23 most powerful women engineers in the world’. In 2016 she received the Computer Research Association’s A. Nico Habermann Award and Brown Engineering Alumni Medal. She was an AAAS-Lemelson Invention Ambassador from 2016 to 2017 which is designed to showcase the modern voices that are addressing the grand challenges facing humanity and to influence policy makers. She also received the Richard A. Tapia Achievement Award in 2018 for her contribution in bringing girls, underrepresented minorities, and people with disabilities into computing through programs related to robotics. In 2020, for the demonstrable and sustained societal impact of her work she received Georgia Tech Outstanding Achievement in Research Innovation Award 2020. In 2020, Howard co-founded the Black in Robotics community organization, and also became the first black woman to achieve IEEE RAS Fellow status for her contributions to human-robot interaction systems. She has more than 350 papers, 4000 citations, and recently published an audiobook “Sex, Race, and Robots: How to Be Human in the Age of AI” about how the tech world’s racial and sexual biases are infecting the next generation of robots and AI, with profoundly negative effects for humans of all genders and races. “Robotics is me, It’s part of my life . I think as engineers we have an amazing power, where we can take people’s wishes and convert them into reality.” says Howard, who also founded Zyrobotics where she has been developing assistive technologies for children with disabilities. “Robots can improve quality of life; Humans inherently trust them”, says Howard in her TedX talk where she explains how humans develop emotional attachments to social or interactive robots. |

Want to keep reading? There are 180 more stories on our 2013 to 2020 lists. Why not nominate someone for inclusion next year!

And we encourage #womeninrobotics and women who’d like to work in robotics to join our professional network at http://womeninrobotics.org

James Bruton focus series #2: Barcode scanner guitar synths

As every other Saturday, I’m bringing you another cool open-source project from James Bruton. Today, how about becoming an experimental musician with your own barcode scanner synthesizer?

I introduced James Bruton in the first post of this focus series on him, where I showed you the Boston Dynamics-inspired open robot dogs projects that consolidated him as one of the top maker on YouTube. As a sort of musician, the barcode synth project I’ve picked for this second post grabbed my attention among the countless videos he’s got on his channel.

To be more specific, the barcode synth consists of two projects. A bit more than a year ago, James showed how to build a four-neck guitar synth with the frets (the place where you put your fingers to play a note on the guitar) being barcodes instead of strings. To play this guitar, you only need a barcode reader connected to an Arduino that converts the data read from the barcodes into a number that represents a MIDI note – which is a digital representation of a musical note based on the MIDI standard. You can then plug the Arduino into a synth or your computer (if you love virtual instruments as much as I do!) to transform the MIDI output into actual sound. Extra features of this guitar included pitch bending and octave shifting buttons. You can access the open-source code of this type of guitar here, and enjoy James’ explanation (and performance) in the following video:

A couple of months ago, James made an improved version of the previous guitar synth. Instead of using the number given by the barcode, for this improved synth he hacked the barcode reader to interpret the barcodes as images so that the output is the raw square wave that it sees. With he help of a Teensy microcontroller to do the digital signal processing and a Raspberry Pi to display barcode images on a screen fitted to a 3D-printed guitar, he could produce a richer range of sounds compared to the previous version. If you want to build you own barcode synth, check out the open-source files and his video (you’ll be impressed to find out how a zebra sounds like!):

Make tech, make music, and stay tuned!

Robots encourage risk-taking behaviour in humans

Using Robots For Inspection, Maintenance, And Repairs

SoftBank sells controlling stake in Boston Dynamics to Hyundai

Getting the right grip: Designing soft and sensitive robotic fingers

Deep reinforcement-learning architecture combines pre-learned skills to create new sets of skills on the fly

Better Data equals Better Navigation

Should robots be gendered? comments on Alan Winfield’s opinion piece

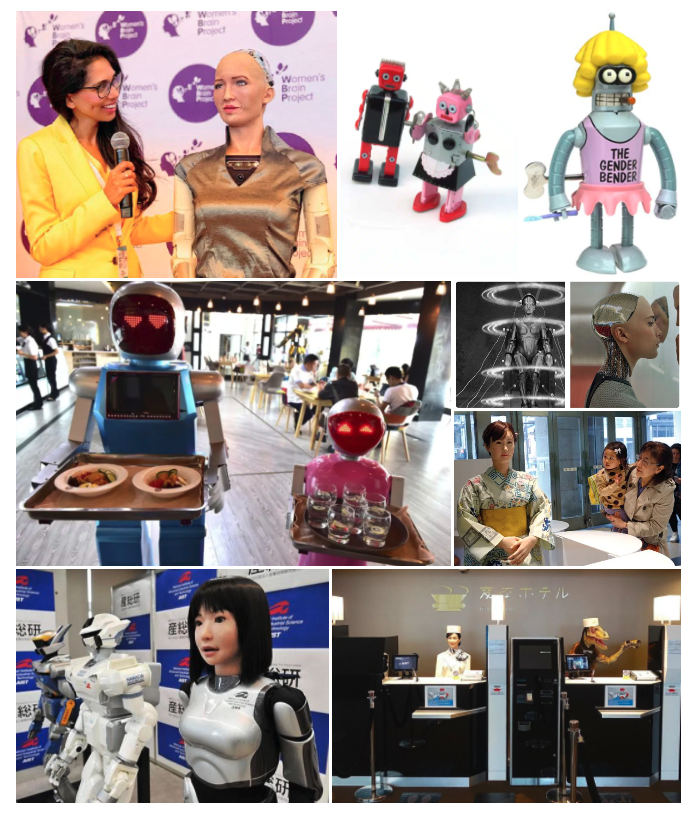

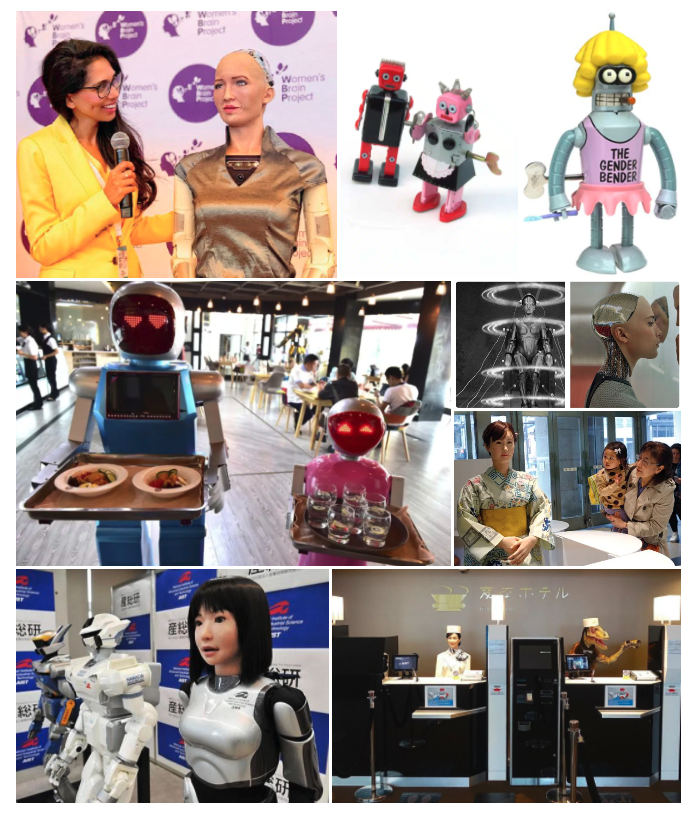

The gendering of robots is something I’ve found fascinating since I first started building robots out of legos with my brother. We all ascribe character to robots, consciously or not, even when we understand exactly how robots work. Until recently we’ve been able to write this off as science fiction stuff, because real robots were boring industrial arms and anything else was fictional. However, since 2010, robots have been rolling out into the real world in a whole range of shapes, characters and notably, stereotypes. My original research on the naming of robots gave some indications as to just how insidious this human tendency to anthropomorphize and gender robots really is. Now we’re starting to face the consequences and it matters.

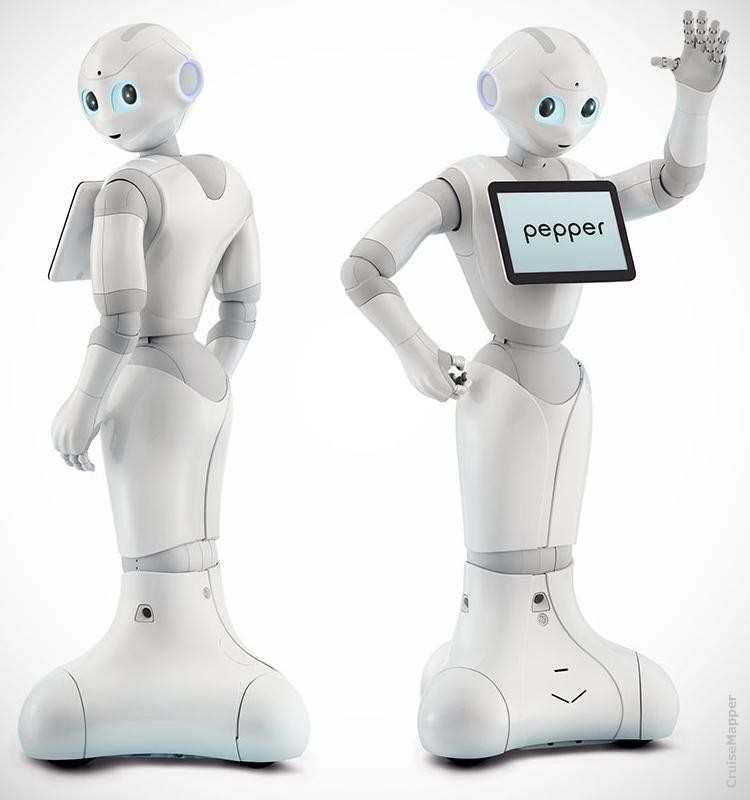

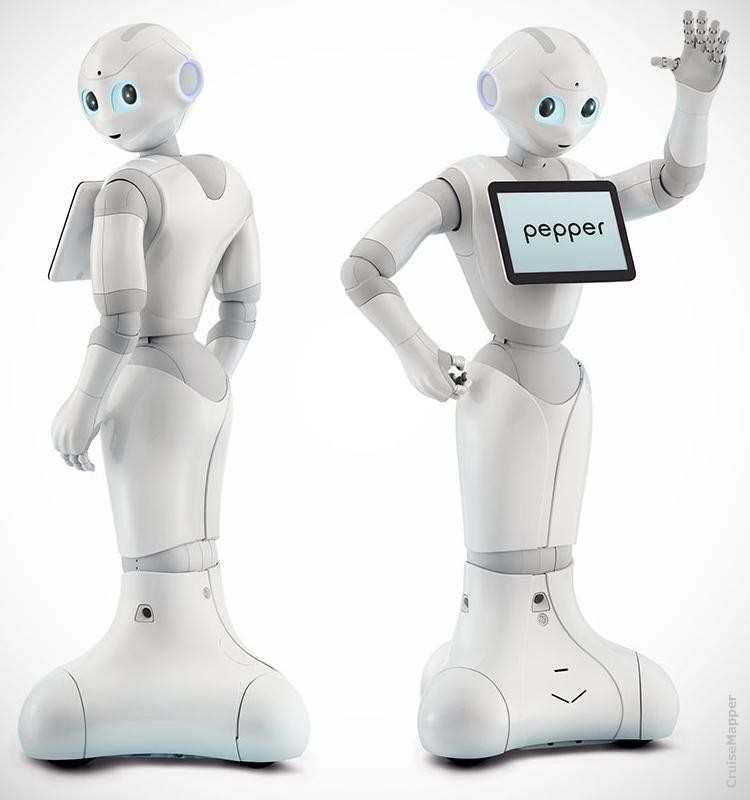

Firstly, let’s consider that many languages have gendered nouns, so there is a preliminary linguistic layer of labelling, ahead of the naming of robots, which if not defined, then tends to happen informally. The founders of two different robot companies have told me that they know when their robot has been accepted in a workplace by when it’s been named by teammates, and they deliberately leave the robot unnamed. Whereas some other companies focus on a more nuanced brand name such as Pepper or Relay, which can minimize gender stereotypes, but even then the effects persist.

Because with robots the physical appearance can’t be ignored and often aligns with ideas of gender. Next, there is the robot voice. Then, there are other layers of operation which can affect both a robot’s learning and its response. And finally, there is the robot’s task or occupation and its socio-cultural context.

Names are both informative and performative. We can usually ascribe a gender to a named object. Similarly, we can ascribe gender based on a robot’s appearance or voice, although it can differ in socio-cultural contexts.

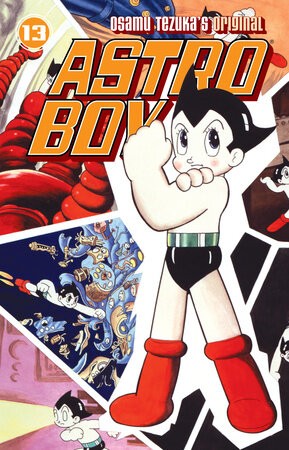

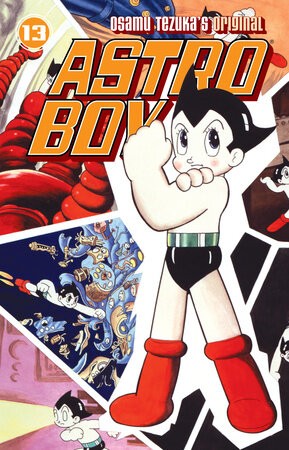

The robot Pepper was designed to be a childlike humanoid and according to SoftBank Robotics, Pepper is gender neutral. But in general, I’ve found that US people tend to see Pepper as female helper, while Asian people are more likely to see Pepper as a boy robot helper. This probably has something to do with the popularity of Astro Boy (Mighty Atom) from 1952 to 1968.

One of the significant issues with gendering robots is that once embodied, individuals are unlikely to have the power to change the robot that they interact with. Even if they rename it, recostume it and change the voice, the residual gender markers will be pervasive and ‘neutral’ will still elicit a gender response in everybody.

This will have an impact on how we treat and trust robots. This also has much deeper social implications for all of us, not just those who interact with robots, as robots are recreating all of our existing gender biases. And once the literal die is cast and robots are rolling out of a factory, it will be very hard to subsequently change the robot body.

Interestingly, I’m noticing a transition from a default male style of robot (think of all the small humanoid fighting, dancing and soccer playing robots) to a default female style of robot as the service robotics industry starts to grow. Even when the robot is simply a box shape on wheels, the use of voice can completely change our perception. One of the pioneering service robots from Savioke, Relay, deliberately preselected a neutral name for their robot and avoided using a human voice completely. Relay makes sounds but doesn’t use words. Just like R2D2, Relay expresses character through beeps and boops. This was a conscious, and significant, design choice for Savioke. Their preliminary experimentation on human-robot interaction showed that robots that spoke were expected to answer questions, and perform tasks at a higher level of competency than a robot that beeped.

Relay from Savioke delivering at Aloft Hotel

Not only did Savioke remove the cognitive dissonance of having a robot seem more human that it really is, but they removed some of the reiterative stereotyping that is starting to occur with less thoughtful robot deployments. The best practice for designing robots for real world interaction is to minimize human expressivity and remove any gender markers. (more about that next).

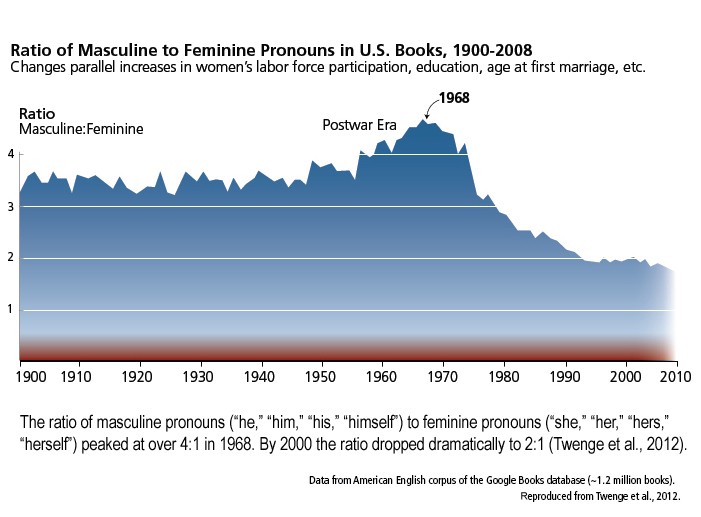

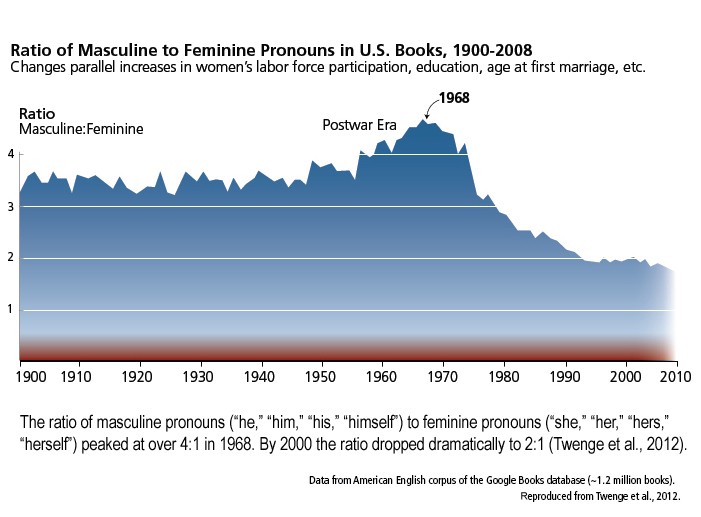

The concept of ‘marked’ and ‘unmarked’ arose in linguistics in the 1930s, but we’ve seen it play out in Natural Language Processing, search and deep learning repeatedly since then, perpetuating, reiterating and exaggerating the use of masculine terminology as the default, and feminine terminology used only in explicit (or marked) circumstances. Marked circumstances almost always relate to sexual characteristics or inferiority within power dynamics, rather than anything more interesting.

An example of unmarked or default terminology is the use of ‘man’ to describe people, but ‘woman’ to only describe a subset of ‘man’. This is also commonly seen in the use of a female specifier on a profession, ie. female police officer, female president, or female doctor. Otherwise, in spite of there being many female doctors, the search will return male examples, call female doctors he, or miscategorize them as nurse. We are all familiar with those mistakes in real life but had developed social policies to reduce the frequency of them. Now AI and robotics are bringing the stereotype back.

And so it happens that the ‘neutral’ physical appearance of robots is usually assumed to be male, rather than female, unless the robot has explicit female features. Sadly, female robots mean either a sexualized robot, or a robot performing a stereotypically female role. This is how people actually see and receive robots unless a company, like Savioke, consciously refrains from triggering our stereotypically gendered responses.

I can vouch for the fact that searching for images using the term “female roboticists”, for example, always presents me with lots of men building female robots instead. It will take a concerted effort to change things. Robot builders have the tendency to give our robots character. And unless you happen to be a very good (and rich) robotics company, there is also no financial incentive to degender robots. Quite the opposite. There is financial pressure to take advantage of our inherent anthropomorphism and gender stereotypes.

In The Media Equation in 1996, Clifford Reeves and Byron Nass demonstrated how we all attributed character, including gender, to our computing machines, and that this then affected our thoughts and actions, even though most people consciously deny conflating a computer with a personality. This unconscious anthropomorphizing can be used to make us respond differently, so of course robot builders will increasingly utilize the effect as more robots enter society and competition increases.

Can human beings relate to computer or television programs in the same way they relate to other human beings? Based on numerous psychological studies, this book concludes that people not only can but do treat computers, televisions, and new media as real people and places. Studies demonstrate that people are “polite” to computers; that they treat computers with female voices differently than “male” ones; that large faces on a screen can invade our personal space; and that on-screen and real-life motion can provoke the same physical responses.

The Media Equation

The history of voice assistants shows a sad trend. These days, they are all female, with the exception of IBM Watson, but then Watson occupies a different ecosystem niche. Watson is an expert. Watson is the doctor to the rest of our subservient, map reading, shopping list helpful nurses. By default, unless you’re in Arabia, your voice assistant device will have a female voice. You have to go through quite a few steps to consciously change it and there are very few options. In 2019, Q, a genderless voice assistant was introduced, however I can’t find it offered on any devices yet.

And while it may be possible to upload a different voice to a robot, there’s nothing we can do if the physical design of the robot evokes gender. Alan Winfield wrote a very good article “Should robots be gendered?” here on Robohub in 2016, in which he outlines three reasons that gendered robots are a bad idea, all stemming from the 4th of the EPSRC Principles of Robotics, that robots should be transparent in action, rather than capitalizing on the illusion of character, so as not to influence vulnerable people.

Robots are manufactured artefacts: the illusion of emotions and intent should not be used to exploit vulnerable users.

My biggest quibble with the EPSRC Principles is underestimating the size of the problem. By stating that vulnerable users are the young or the elderly, the principles imply that the rest of us are immune from emotional reaction to robots, whereas Reeves and Nass clearly show the opposite. We are all easily manipulated by our digital voice and robot assistants. And while Winfield recognizes that gender queues are powerful enough to elicit a response in everybody, he only sees the explicit gender markers rather than understanding that unmarked or neutral seeming robots also elicit a gendered response, as ‘not female’.

So Winfield’s first concern is emotional manipulation for vulnerable users (all of us!), his second concern is anthropomorphism inducing cognitive dissonance (over promising and under delivering), and his final concern is that the all the negative stereotypes contributing to sexism will be reproduced and reiterated as normal through the introduction of gendered robots in stereotyped roles (it’s happening!). These are all valid concerns, and yet while we’re just waking up to the problem, the service robot industry is growing by more than 30% per annum.

Where the growth of the industrial robotics segment is comparatively predictable, the world’s most trusted robotics statistics body, the International Federation of Robotics is consistently underestimating the growth of the service robotics industry. In 2016, the IFR predicted 10% growth for professional service robotics over the next few years from \$4.6 Billion, but by 2018 they were recording 61% growth to \$12.6B and by 2020 the IFR has recorded 85% overall growth expecting revenue from service robotics to hit \$37B by 2021.

It’s unlikely that we’ll recall robots, once designed, built and deployed, for anything other than a physical safety issue. And the gendering of robots isn’t something we can roll out a software update to fix. We need to start requesting companies to not deploy robots that reinforce gender stereotyping. They can still be cute and lovable, I’m not opposed to the R2D2 robot stereotype!

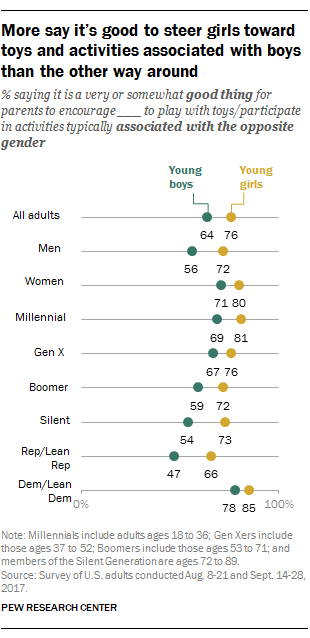

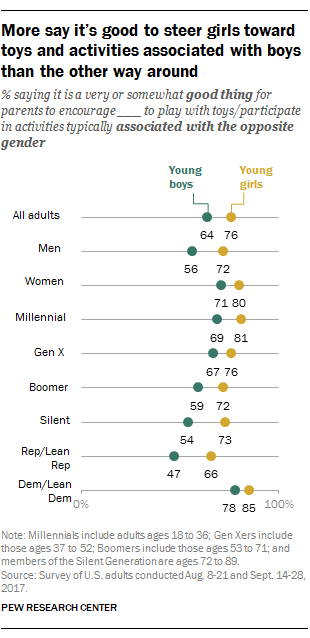

Consumers are starting to fight back against the gender stereotyping of toys, which really only started in the 20th century as a way to extract more money from parents, and some brands are realizing that there’s an opportunity for them in developing gender neutral toys. Recent research from the Pew Research Center found that overall 64% of US adults wanted boys to play with toys associated with girls, and 76% of US adults wanted girls to play with toys associated with boys. The difference between girls and boys can be explained because girls’ role playing (caring and nurturing) is still seen as more negative than boys’ roles (fighting and leadership). But the overall range that shows that society has developed a real desire to avoid gender stereotyping completely.

Sadly, it’s like knowing sugar is bad for us, while it still tastes sweet.

In 2016, I debated Ben Goertzel, maker of Sophia the Robot, on the main stage of the Web Summit on whether humanoid robots were good or bad. I believe I made the better case in terms of argument, but ultimately the crowd sided with Goertzel, and by default with Sophia. (there are a couple of descriptions of the debate referenced below).

Robots are still bright shiny new toys to us. When are we going to realize that we’ve already opened the box and played this game, and women, or any underrepresented group, or any stereotype role, is going to be the loser. No, we’re all going to lose! Because we don’t want these stereotypes any more and robots are just going to reinforce the stereotypes that we already know we don’t want.

And did I mention how white all the robots are? Yes, they are racially stereotyped too. (See Ayanna Howard’s new book “Sex, Race and Robots: How to be human in an age of AI”)

References:

- https://robohub.org/robots-should-not-be-gendered/

- https://genderedinnovations.stanford.edu/case-studies/nlp.html

- https://www.researchgate.net/publication/37705092_The_Media_Equation_How_People_Treat_Computers_Television_and_New_Media_Like_Real_People_and_Pla

- https://www.wsj.com/articles/alexa-siri-cortana-the-problem-with-all-female-digital-assistants-1487709068

- https://en.unesco.org/Id-blush-if-I-could

- https://epsrc.ukri.org/research/ourportfolio/themes/engineering/activities/principlesofrobotics/

- https://transmitter.ieee.org/web-summit-debate-robots-people/

- https://medium.com/@kyecass/should-robots-look-and-act-like-humans-35790e8005b3

- https://cristinaturbatu.wordpress.com/2016/11/16/web-summit-lisbon-2016/

- https://www.therobotreport.com/ifrs-two-reports-for-2015-show-double-digit-growth-for-remainder-of-decade/

- https://www.roboticsbusinessreview.com/research/world-robotics-report-global-sales-of-robots-hit-16-5b-in-2018/

- https://www.robotics.org/service-robots/what-are-professional-service-robots

- https://theconversation.com/how-toys-became-gendered-and-why-itll-take-more-than-a-gender-neutral-doll-to-change-how-boys-perceive-femininity-124386

- https://www.pewresearch.org/fact-tank/2017/12/19/most-americans-see-value-in-steering-children-toward-toys-activities-associated-with-opposite-gender/

- https://observer.com/2019/08/robot-racial-bias-study/

- https://www.marketplace.org/shows/marketplace-tech/should-robots-have-gender-or-ethnicity-one-roboticist-says-no-ayanna-howard-sex-race-robots/

Should robots be gendered? comments on Alan Winfield’s opinion piece

The gendering of robots is something I’ve found fascinating since I first started building robots out of legos with my brother. We all ascribe character to robots, consciously or not, even when we understand exactly how robots work. Until recently we’ve been able to write this off as science fiction stuff, because real robots were boring industrial arms and anything else was fictional. However, since 2010, robots have been rolling out into the real world in a whole range of shapes, characters and notably, stereotypes. My original research on the naming of robots gave some indications as to just how insidious this human tendency to anthropomorphize and gender robots really is. Now we’re starting to face the consequences and it matters.

Firstly, let’s consider that many languages have gendered nouns, so there is a preliminary linguistic layer of labelling, ahead of the naming of robots, which if not defined, then tends to happen informally. The founders of two different robot companies have told me that they know when their robot has been accepted in a workplace by when it’s been named by teammates, and they deliberately leave the robot unnamed. Whereas some other companies focus on a more nuanced brand name such as Pepper or Relay, which can minimize gender stereotypes, but even then the effects persist.

Because with robots the physical appearance can’t be ignored and often aligns with ideas of gender. Next, there is the robot voice. Then, there are other layers of operation which can affect both a robot’s learning and its response. And finally, there is the robot’s task or occupation and its socio-cultural context.

Names are both informative and performative. We can usually ascribe a gender to a named object. Similarly, we can ascribe gender based on a robot’s appearance or voice, although it can differ in socio-cultural contexts.

The robot Pepper was designed to be a childlike humanoid and according to SoftBank Robotics, Pepper is gender neutral. But in general, I’ve found that US people tend to see Pepper as female helper, while Asian people are more likely to see Pepper as a boy robot helper. This probably has something to do with the popularity of Astro Boy (Mighty Atom) from 1952 to 1968.

One of the significant issues with gendering robots is that once embodied, individuals are unlikely to have the power to change the robot that they interact with. Even if they rename it, recostume it and change the voice, the residual gender markers will be pervasive and ‘neutral’ will still elicit a gender response in everybody.

This will have an impact on how we treat and trust robots. This also has much deeper social implications for all of us, not just those who interact with robots, as robots are recreating all of our existing gender biases. And once the literal die is cast and robots are rolling out of a factory, it will be very hard to subsequently change the robot body.

Interestingly, I’m noticing a transition from a default male style of robot (think of all the small humanoid fighting, dancing and soccer playing robots) to a default female style of robot as the service robotics industry starts to grow. Even when the robot is simply a box shape on wheels, the use of voice can completely change our perception. One of the pioneering service robots from Savioke, Relay, deliberately preselected a neutral name for their robot and avoided using a human voice completely. Relay makes sounds but doesn’t use words. Just like R2D2, Relay expresses character through beeps and boops. This was a conscious, and significant, design choice for Savioke. Their preliminary experimentation on human-robot interaction showed that robots that spoke were expected to answer questions, and perform tasks at a higher level of competency than a robot that beeped.

Relay from Savioke delivering at Aloft Hotel

Not only did Savioke remove the cognitive dissonance of having a robot seem more human that it really is, but they removed some of the reiterative stereotyping that is starting to occur with less thoughtful robot deployments. The best practice for designing robots for real world interaction is to minimize human expressivity and remove any gender markers. (more about that next).

The concept of ‘marked’ and ‘unmarked’ arose in linguistics in the 1930s, but we’ve seen it play out in Natural Language Processing, search and deep learning repeatedly since then, perpetuating, reiterating and exaggerating the use of masculine terminology as the default, and feminine terminology used only in explicit (or marked) circumstances. Marked circumstances almost always relate to sexual characteristics or inferiority within power dynamics, rather than anything more interesting.

An example of unmarked or default terminology is the use of ‘man’ to describe people, but ‘woman’ to only describe a subset of ‘man’. This is also commonly seen in the use of a female specifier on a profession, ie. female police officer, female president, or female doctor. Otherwise, in spite of there being many female doctors, the search will return male examples, call female doctors he, or miscategorize them as nurse. We are all familiar with those mistakes in real life but had developed social policies to reduce the frequency of them. Now AI and robotics are bringing the stereotype back.

And so it happens that the ‘neutral’ physical appearance of robots is usually assumed to be male, rather than female, unless the robot has explicit female features. Sadly, female robots mean either a sexualized robot, or a robot performing a stereotypically female role. This is how people actually see and receive robots unless a company, like Savioke, consciously refrains from triggering our stereotypically gendered responses.

I can vouch for the fact that searching for images using the term “female roboticists”, for example, always presents me with lots of men building female robots instead. It will take a concerted effort to change things. Robot builders have the tendency to give our robots character. And unless you happen to be a very good (and rich) robotics company, there is also no financial incentive to degender robots. Quite the opposite. There is financial pressure to take advantage of our inherent anthropomorphism and gender stereotypes.

In The Media Equation in 1996, Clifford Reeves and Byron Nass demonstrated how we all attributed character, including gender, to our computing machines, and that this then affected our thoughts and actions, even though most people consciously deny conflating a computer with a personality. This unconscious anthropomorphizing can be used to make us respond differently, so of course robot builders will increasingly utilize the effect as more robots enter society and competition increases.

Can human beings relate to computer or television programs in the same way they relate to other human beings? Based on numerous psychological studies, this book concludes that people not only can but do treat computers, televisions, and new media as real people and places. Studies demonstrate that people are “polite” to computers; that they treat computers with female voices differently than “male” ones; that large faces on a screen can invade our personal space; and that on-screen and real-life motion can provoke the same physical responses.

The Media Equation

The history of voice assistants shows a sad trend. These days, they are all female, with the exception of IBM Watson, but then Watson occupies a different ecosystem niche. Watson is an expert. Watson is the doctor to the rest of our subservient, map reading, shopping list helpful nurses. By default, unless you’re in Arabia, your voice assistant device will have a female voice. You have to go through quite a few steps to consciously change it and there are very few options. In 2019, Q, a genderless voice assistant was introduced, however I can’t find it offered on any devices yet.

And while it may be possible to upload a different voice to a robot, there’s nothing we can do if the physical design of the robot evokes gender. Alan Winfield wrote a very good article “Should robots be gendered?” here on Robohub in 2016, in which he outlines three reasons that gendered robots are a bad idea, all stemming from the 4th of the EPSRC Principles of Robotics, that robots should be transparent in action, rather than capitalizing on the illusion of character, so as not to influence vulnerable people.

Robots are manufactured artefacts: the illusion of emotions and intent should not be used to exploit vulnerable users.

My biggest quibble with the EPSRC Principles is underestimating the size of the problem. By stating that vulnerable users are the young or the elderly, the principles imply that the rest of us are immune from emotional reaction to robots, whereas Reeves and Nass clearly show the opposite. We are all easily manipulated by our digital voice and robot assistants. And while Winfield recognizes that gender queues are powerful enough to elicit a response in everybody, he only sees the explicit gender markers rather than understanding that unmarked or neutral seeming robots also elicit a gendered response, as ‘not female’.

So Winfield’s first concern is emotional manipulation for vulnerable users (all of us!), his second concern is anthropomorphism inducing cognitive dissonance (over promising and under delivering), and his final concern is that the all the negative stereotypes contributing to sexism will be reproduced and reiterated as normal through the introduction of gendered robots in stereotyped roles (it’s happening!). These are all valid concerns, and yet while we’re just waking up to the problem, the service robot industry is growing by more than 30% per annum.

Where the growth of the industrial robotics segment is comparatively predictable, the world’s most trusted robotics statistics body, the International Federation of Robotics is consistently underestimating the growth of the service robotics industry. In 2016, the IFR predicted 10% growth for professional service robotics over the next few years from \$4.6 Billion, but by 2018 they were recording 61% growth to \$12.6B and by 2020 the IFR has recorded 85% overall growth expecting revenue from service robotics to hit \$37B by 2021.

It’s unlikely that we’ll recall robots, once designed, built and deployed, for anything other than a physical safety issue. And the gendering of robots isn’t something we can roll out a software update to fix. We need to start requesting companies to not deploy robots that reinforce gender stereotyping. They can still be cute and lovable, I’m not opposed to the R2D2 robot stereotype!

Consumers are starting to fight back against the gender stereotyping of toys, which really only started in the 20th century as a way to extract more money from parents, and some brands are realizing that there’s an opportunity for them in developing gender neutral toys. Recent research from the Pew Research Center found that overall 64% of US adults wanted boys to play with toys associated with girls, and 76% of US adults wanted girls to play with toys associated with boys. The difference between girls and boys can be explained because girls’ role playing (caring and nurturing) is still seen as more negative than boys’ roles (fighting and leadership). But the overall range that shows that society has developed a real desire to avoid gender stereotyping completely.

Sadly, it’s like knowing sugar is bad for us, while it still tastes sweet.

In 2016, I debated Ben Goertzel, maker of Sophia the Robot, on the main stage of the Web Summit on whether humanoid robots were good or bad. I believe I made the better case in terms of argument, but ultimately the crowd sided with Goertzel, and by default with Sophia. (there are a couple of descriptions of the debate referenced below).

Robots are still bright shiny new toys to us. When are we going to realize that we’ve already opened the box and played this game, and women, or any underrepresented group, or any stereotype role, is going to be the loser. No, we’re all going to lose! Because we don’t want these stereotypes any more and robots are just going to reinforce the stereotypes that we already know we don’t want.

And did I mention how white all the robots are? Yes, they are racially stereotyped too. (See Ayanna Howard’s new book “Sex, Race and Robots: How to be human in an age of AI”)

References:

- https://robohub.org/robots-should-not-be-gendered/

- https://genderedinnovations.stanford.edu/case-studies/nlp.html

- https://www.researchgate.net/publication/37705092_The_Media_Equation_How_People_Treat_Computers_Television_and_New_Media_Like_Real_People_and_Pla

- https://www.wsj.com/articles/alexa-siri-cortana-the-problem-with-all-female-digital-assistants-1487709068

- https://en.unesco.org/Id-blush-if-I-could

- https://epsrc.ukri.org/research/ourportfolio/themes/engineering/activities/principlesofrobotics/

- https://transmitter.ieee.org/web-summit-debate-robots-people/

- https://medium.com/@kyecass/should-robots-look-and-act-like-humans-35790e8005b3

- https://cristinaturbatu.wordpress.com/2016/11/16/web-summit-lisbon-2016/

- https://www.therobotreport.com/ifrs-two-reports-for-2015-show-double-digit-growth-for-remainder-of-decade/

- https://www.roboticsbusinessreview.com/research/world-robotics-report-global-sales-of-robots-hit-16-5b-in-2018/

- https://www.robotics.org/service-robots/what-are-professional-service-robots

- https://theconversation.com/how-toys-became-gendered-and-why-itll-take-more-than-a-gender-neutral-doll-to-change-how-boys-perceive-femininity-124386

- https://www.pewresearch.org/fact-tank/2017/12/19/most-americans-see-value-in-steering-children-toward-toys-activities-associated-with-opposite-gender/

- https://observer.com/2019/08/robot-racial-bias-study/

- https://www.marketplace.org/shows/marketplace-tech/should-robots-have-gender-or-ethnicity-one-roboticist-says-no-ayanna-howard-sex-race-robots/