By Deborah Pirchner

Malaria is an infectious disease claiming more than half a million lives each year. Because traditional diagnosis takes expertise and the workload is high, an international team of researchers investigated if diagnosis using a new system combining an automatic scanning microscope and AI is feasible in clinical settings. They found that the system identified malaria parasites almost as accurately as experts staffing microscopes used in standard diagnostic procedures. This may help reduce the burden on microscopists and increase the feasible patient load.

Each year, more than 200 million people fall sick with malaria and more than half a million of these infections lead to death. The World Health Organization recommends parasite-based diagnosis before starting treatment for the disease caused by Plasmodium parasites. There are various diagnostic methods, including conventional light microscopy, rapid diagnostic tests and PCR.

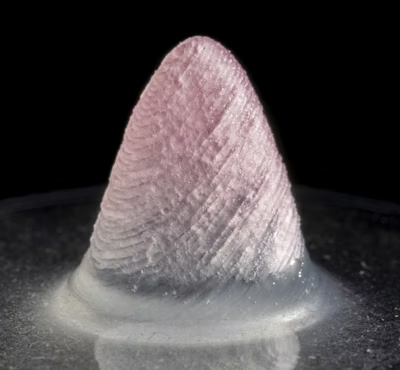

The standard for malaria diagnosis, however, remains manual light microscopy, during which a specialist examines blood films with a microscope to confirm the presence of malaria parasites. Yet, the accuracy of the results depends critically on the skills of the microscopist and can be hampered by fatigue caused by excessive workloads of the professionals doing the testing.

Now, writing in Frontiers in Malaria, an international team of researchers has assessed whether a fully automated system, combining AI detection software and an automated microscope, can diagnose malaria with clinically useful accuracy.

“At an 88% diagnostic accuracy rate relative to microscopists, the AI system identified malaria parasites almost, though not quite, as well as experts,” said Dr Roxanne Rees-Channer, a researcher at The Hospital for Tropical Diseases at UCLH in the UK, where the study was performed. “This level of performance in a clinical setting is a major achievement for AI algorithms targeting malaria. It indicates that the system can indeed be a clinically useful tool for malaria diagnosis in appropriate settings.”

AI delivers accurate diagnosis

The researchers sampled more than 1,200 blood samples of travelers who had returned to the UK from malaria-endemic countries. The study tested the accuracy of the AI and automated microscope system in a true clinical setting under ideal conditions.

They evaluated samples using both manual light microscopy and the AI-microscope system. By hand, 113 samples were diagnosed as malaria parasite positive, whereas the AI-system correctly identified 99 samples as positive, which corresponds to an 88% accuracy rate.

“AI for medicine often posts rosy preliminary results on internal datasets, but then falls flat in real clinical settings. This study independently assessed whether the AI system could succeed in a true clinical use case,” said Rees-Channer, who is also the lead author of the study.

Automated vs manual

The fully automated malaria diagnostic system the researchers put to the test includes hard- as well as software. An automated microscopy platform scans blood films and malaria detection algorithms process the image to detect parasites and the quantity present.

Automated malaria diagnosis has several potential benefits, the scientists pointed out. “Even expert microscopists can become fatigued and make mistakes, especially under a heavy workload,” Rees-Channer explained. “Automated diagnosis of malaria using AI could reduce this burden for microscopists and thus increase the feasible patient load.” Furthermore, these systems deliver reproducible results and can be widely deployed, the scientists wrote.

Despite the 88% accuracy rate, the automated system also falsely identified 122 samples as positive, which can lead to patients receiving unnecessary anti-malarial drugs. “The AI software is still not as accurate as an expert microscopist. This study represents a promising datapoint rather than a decisive proof of fitness,” Rees-Channer concluded.

Read the research in full

Evaluation of an automated microscope using machine learning for the detection of malaria in travelers returned to the UK, Roxanne R. Rees-Channer, Christine M. Bachman, Lynn Grignard, Michelle L. Gatton, Stephen Burkot, Matthew P. Horning, Charles B. Delahunt, Liming Hu, Courosh Mehanian, Clay M. Thompson, Katherine Woods, Paul Lansdell, Sonal Shah, Peter L. Chiodini, Frontiers in Malaria (2023).