Year end summary: Top Robocar stories of 2022

Here’s my annual summary of the top stories of the prior year. This time the news was a strong mix of bad and good.

Read the text story on Forbes.com at Robocars 2022 year in review.

And see the video version here:

AGV or Conveyor — Which System Should You Choose?

New technology revolutionizing mobile robot fleets

Futuristic fields: Europe’s farm industry on cusp of robot revolution

Artificial intelligence is set to revolutionise agriculture by helping farmers meet field-hand needs and identify diseased plants. © baranozdemir, iStock

In the Dutch province of Zeeland, a robot moves swiftly through a field of crops including sunflowers, shallots and onions. The machine weeds autonomously – and tirelessly – day in, day out.

“Farmdroid” has made life a lot easier for Mark Buijze, who runs a biological farm with 50 cows and 15 hectares of land. Buijze is one of the very few owners of robots in European agriculture.

Robots to the rescue

His electronic field worker uses GPS and is multifunctional, switching between weeding and seeding. With the push of a button, all Buijze has to do is enter coordinates and Farmdroid takes it from there.

‘With the robot, the weeding can be finished within one to two days – a task that would normally take weeks and roughly four to five workers if done by hand,’ he said. ‘By using GPS, the machine can identify the exact location of where it has to go in the field.’

About 12 000 years ago, the end of foraging and start of agriculture heralded big improvements in people’s quality of life. Few sectors have a history as rich as that of farming, which has evolved over the centuries in step with technological advancements.

In the current era, however, agriculture has been slower than other industries to follow one tech trend: artificial intelligence (AI). While already commonly used in forms ranging from automated chatbots and face recognition to car braking and warehouse controls, AI for agriculture is still in the early stages of development.

Now, advances in research are spurring farmers to embrace robots by showing how they can do everything from meeting field-hand needs to detecting crop diseases early.

Lean and green

For French agronomist Bertrand Pinel, farming in Europe will require far greater use of robots to be productive, competitive and green – three top EU goals for a sector whose output is worth around €190 billion a year.

“Labour is one of the biggest obstacles in agriculture.”

– Fritz van Evert, ROBS4CROPS

One reason for using robots is the need to forgo the use of herbicides by eliminating weeds the old-fashioned way: mechanical weeding, a task that is not just mundane but also arduous and time consuming. Another is the frequent shortage of workers to prune grapevines.

‘In both cases, robots would help,’ said Pinel, who is research and development project manager at France-based Terrena Innovation. ‘That is our idea of the future for European agriculture.’

Pinel is part of the EU-funded ROBS4CROPS project. With some 50 experts and 16 institutional partners involved, it is pioneering a robot technology on participating farms in the Netherlands, Greece, Spain and France.

‘This initiative is quite innovative,’ said Frits van Evert, coordinator of the project. ‘It has not been done before.’

In the weeds

AI in agriculture looks promising for tasks that need to be repeated throughout the year such as weeding, according to van Evert, a senior researcher in precision agriculture at Wageningen University in the Netherlands.

‘If you grow a crop like potatoes, typically you plant the crop once per year in the spring and you harvest in the fall, but the weeding has to be done somewhere between six and 10 times per year,’ he said.

Plus, there is the question of speed. Often machines work faster than any human being can.

“With this robot everything is done in the field.”

– Francisco Javier Nieto De Santos, FLEXIGROBOTS

Francisco Javier Nieto De Santos, coordinator of the EU-funded FLEXIGROBOTS project, is particularly impressed by a model robot that takes soil samples. When done by hand, this practice requires special care to avoid contamination, delivery to a laboratory and days of analysis.

‘With this robot everything is done in the field,’ De Santos said. ‘It can take several samples per hour, providing results within a matter of minutes.’

Eventually, he said, the benefits of such technologies will extend beyond the farm industry to reach the general public by increasing the overall supply of food.

Unloved labour

Meanwhile, agricultural robots may be in demand not because they can work faster than any person but simply because no people are available for the job.

Even before inflation rates and fertiliser prices began to surge in 2021 amid an energy squeeze made worse by Russia’s invasion of Ukraine this year, farmers across Europe were struggling on another front: finding enough field hands including seasonal workers.

‘Labour is one of the biggest obstacles in agriculture,’ said van Evert. ‘It’s costly and hard to get these days because fewer and fewer people are willing to work in agriculture. We think that robots, such as self-driving tractors, can take away this obstacle.’

The idea behind ROBS4CROPS is to create a robotic system where existing agricultural machinery is upgraded so it can work in tandem with farm robots.

For the system to work, raw data such as images or videos must first be labelled by researchers in ways than can later be read by the AI.

Driverless tractors

The system then uses these large amounts of information to make “smart” decisions as well as predictions – think about the autocorrect feature on laptop computers and mobile phones, for example.

A farming controller comparable to the “brain” of the whole operation decides what needs to happen next or how much work remains to be done and where – based on information from maps or instructions provided by the farmer.

The machinery – self-driving tractors and smart implements like weeders equipped with sensors and cameras – gathers and stores more information as it works, becoming “smarter”.

Crop protection

FLEXIGROBOTS, based in Spain, aims to help farmers use existing robots for multiple tasks including disease detection.

Take drones, for example. Because they can spot a diseased plant from the air, drones can help farmers detect sick crops early and prevent a wider infestation.

‘If you can’t detect diseases in an early stage, you may lose the produce of an entire field, the production of an entire year,’ said De Santos. ‘The only option is to remove the infected plant.’

For example, there is no treatment for the fungus known as mildew, so identifying and removing diseased plants early on is crucial.

Pooling information is key to making the whole system smarter, De Santos said. Sharing data gathered by drones with robots or feeding the information into models expands the “intelligence” of the machines.

Although agronomist Pinel doesn’t believe that agriculture will ever be solely reliant on robotics, he’s certain about their revolutionary impact.

‘In the future, we hope that the farmers can just put a couple of small robots in the field and let them work all day,’ he said.

Research in this article was funded by the EU. If you liked this article, please consider sharing it on social media.

Watch the video

This article was originally published in Horizon, the EU Research and Innovation magazine.

Best of CES 2023: High-tech eyebrows and a boba tea robot

CES 2023: Exwayz to showcase the 1st plug and play software that will guide 100 million autonomous robots

Smart ‘Joey’ bots could soon swarm underground to clean and inspect our pipes

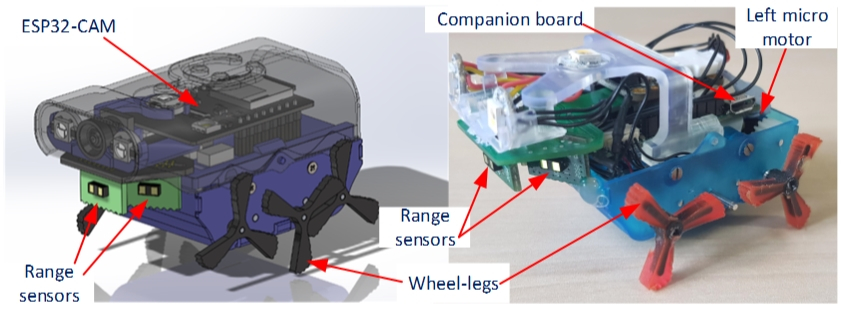

Joey’s design. Image credit: TL Nguyen, A Blight, A Pickering, A Barber, GH Jackson-Mills, JH Boyle, R Richardson, M Dogar, N Cohen

By Mischa Dijkstra, Frontiers science writer

Researchers from the University of Leeds have developed the first mini-robot, called Joey, that can find its own way independently through networks of narrow pipes underground, to inspect any damage or leaks. Joeys are cheap to produce, smart, small, and light, and can move through pipes inclined at a slope or over slippery or muddy sediment at the bottom of the pipes. Future versions of Joey will operate in swarms, with their mobile base on a larger ‘mother’ robot Kanga, which will be equipped with arms and tools for repairs to the pipes.

Beneath our streets lies a maze of pipes, conduits for water, sewage, and gas. Regular inspection of these pipes for leaks, or repair, normally requires these to be dug up. The latter is not only onerous and expensive – with an estimated annual cost of £5.5bn in the UK alone – but causes disruption to traffic as well as nuisance to people living nearby, not to mention damage to the environment.

Now imagine a robot that can find its way through the narrowest of pipe networks and relay images of damage or obstructions to human operators. This isn’t a pipedream anymore, shows a study in Frontiers in Robotics and AI by a team of researchers from the University of Leeds.

“Here we present Joey – a new miniature robot – and show that Joeys can explore real pipe networks completely on their own, without even needing a camera to navigate,” said Dr Netta Cohen, a professor at the University of Leeds and the final author on the study.

Joey is the first to be able to navigate all by itself through mazes of pipes as narrow as 7.5 cm across. Weighing just 70 g, it’s small enough to fit in the palm of your hand.

Pipebots project

The present work forms part of the ‘Pipebots’ project of the universities of Sheffield, Bristol, Birmingham, and Leeds, in collaboration with UK utility companies and other international academic and industrial partners.

First author Dr Thanh Luan Nguyen, a postdoctoral scientist at the University of Leeds who developed Joey’s control algorithms (or ‘brain’), said: “Underground water and sewer networks are some of the least hospitable environments, not only for humans, but also for robots. Sat Nav is not accessible undergound. And Joeys are tiny, so have to function with very simple motors, sensors, and computers that take little space, while the small batteries must be able to operate for long enough.”

Joey moves on 3D-printed ‘wheel-legs’ that roll through straight sections and walk over small obstacles. It is equipped with a range of energy-efficient sensors that measure its distance to walls, junctions, and corners, navigational tools, a microphone, and a camera and ‘spot lights’ to film faults in the pipe network and save the images. The prototype cost only £300 to produce.

Mud and slippery slopes

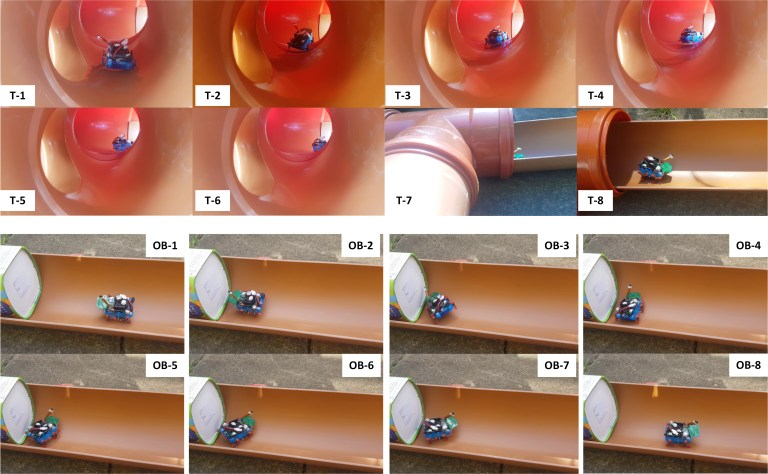

The team showed that Joey is able to find its way, without any instructions from human operators, through an experimental network of pipes including a T-junction, a left and right corner, a dead-end, an obstacle, and three straight sections. On average, Joey managed to explore about one meter of pipe network in just over 45 seconds.

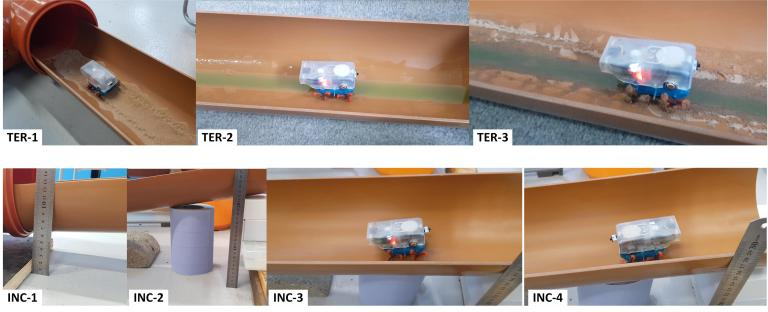

To make life more difficult for the robot, the researchers verified that the robot easily moves up and down inclined pipes with realistic slopes. And to test Joey’s ability to navigate through muddy or slippery tubes, they also added sand and gooey gel (actually dishwashing liquid) to the pipes – again with success.

Importantly, the sensors are enough to allow Joey to navigate without the need to turn on the camera or use power-hungry computer vision. This saves energy and extends Joey’s current battery life. Whenever the battery runs low, Joey will return to its point of origin, to ‘feed’ on power.

Currently, Joeys have one weakness: they can’t right themselves if they inadvertently turn on their back, like an upside-down tortoise. The authors suggest that the next prototype will be able to overcome this challenge. Future generations of Joey should also be waterproof, to operate underwater in pipes entirely filled with liquid.

Joey’s future is collaborative

The Pipebots scientists aim to develop a swarm of Joeys that communicate and work together, based off a larger ‘mother’ robot named Kanga. Kanga, currently under development and testing by some of the same authors at Leeds School of Computing, will be equipped with more sophisticated sensors and repair tools such as robot arms, and carry multiple Joeys.

“Ultimately we hope to design a system that can inspect and map the condition of extensive pipe networks, monitor the pipes over time, and even execute some maintenance and repair tasks,” said Cohen.

“We envision the technology to scale up and diversify, creating an ecology of multi-species of robots that collaborate underground. In this scenario, groups of Joeys would be deployed by larger robots that have more power and capabilities but are restricted to the larger pipes. Meeting this challenge will require more research, development, and testing over 10 to 20 years. It may start to come into play around 2040 or 2050.”

Top half: navigating through a T-junction in the pipe network. Bottom half: encountering an obstruction and turning back. Image credit: TL Nguyen, A Blight, A Pickering, A Barber, GH Jackson-Mills, JH Boyle, R Richardson, M Dogar, N Cohen

Top half: moving through sand, slippery goo, or mud. Bottom half: moving through pipe sloped at an angle. Image credit: TL Nguyen, A Blight, A Pickering, A Barber, GH Jackson-Mills, JH Boyle, R Richardson, M Dogar, N Cohen