Researchers incorporate computer vision and uncertainty into AI for robotic prosthetics

Observations of robotic swarm behavior can help workers safely navigate disaster sites

Using deep learning to give robotic fingertips a sense of touch

Business Perspectives and the Impacts of COVID-19 – Q&A with FAULHABER MICROMO

RoboBusiness Direct Online Series

On the Track of Old Masters

GANs in computer vision – semantic image synthesis and learning a generative model from a single image

Rocos Partners With Boston Dynamics to Upskill Autonomous Spot Robots With Remote Operation – All the Way From New Zealand

Bioinspired micro-robot based on white blood cells

Using Mesh Network Applications for Robotics

Researchers build a fast-moving jumping soft robot

CIMON-XPANEL – Industrial Operating Touch Panel

Boyce Technologies designs and mass produces FDA-approved ventilators in just 30 days

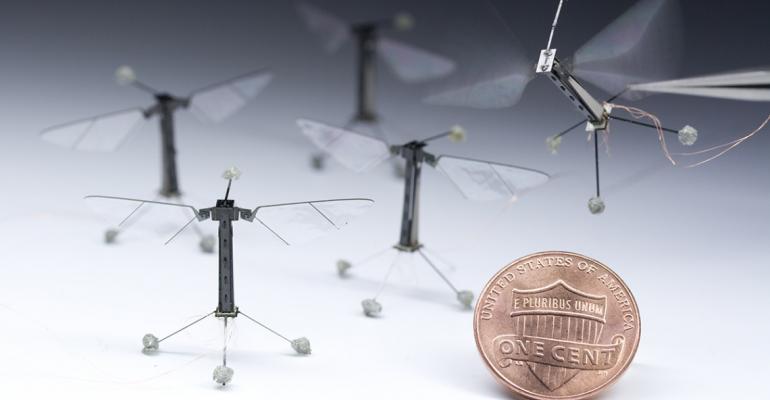

#310: RoboBee’s Untethered Flight, with Farrell Helbling

In this episode, Kate Zhou interviews Farrell Helbling, postdoctoral fellow at Harvard Microrobotics lab, who has worked on developing the RoboBee, an insect-inspired robot that is the lightest vehicle to achieve untethered flight. Farrell discusses challenges with building the robot at centimeter-scale as well as integration of sensors and power electronics particularly in considerations with weight trade-offs.

Farrell Helbling

Farrell Helbling is a post doctoral fellow at Harvard University, where she focuses on the systems-level design of the Harvard RoboBee, an insect-scale flapping wing robot. Her research looks at the integration of the control system, sensors, and power electronics within the strict weight and power constraints of the vehicle. Her work led to the first untethered flight of an insect scale vehicle and was recently featured on the cover of Nature. She is the recipient of a NSF Graduate Research Fellowship, a 2018 Rising Star in EECS, and co-author on the IROS 2015 Best Student Paper for an insect-scale, hybrid aerial-aquatic vehicle. Her work on the RoboBee project is also featured at the Boston Museum of Science, World Economic Forum, London Science Museum, and the Smithsonian, as well as in the popular press (PBS NewsHour, The New York Times, Science Friday, BBC, and Wired). She is interested in the codesign of mechanical and electrical systems for mass-, power-, and computation-constrained robots.

Links