RTOS for Safety Critical Systems

#253: eSIM in Wearable Technology, with Karl Weaver

In this episode, Audrow Nash speaks with Karl Weaver (魏卡爾), formerly the Original Equipment Manufacturer Business Development Director for Oasis Smart SIM. Weaver discusses how wearable technology is growing as a form of payment system in China. He speaks about wireless technology, including Near-Field Communications (NFC) and Embedded SIM cards (eSIM), in wearable technology and in other applications, such as bike rental.

Karl Weaver (魏卡爾)

Since the recording of this interview, Karl has begun working for ARM promoting eSIM and iUICC to Greater China and Asia.

Karl Weaver (魏卡爾) previously worked as the Original Equipment Manufacturer Business Development Director (North America and Northeast Asia) for Oasis Smart SIM. Prior to Oasis, Karl worked for Rivetz Corp, a Massachusetts-based start-up to promote developer tools for design-in of TEE-enables applications on Smartphones for payment and security. Karl also spent 5 years working in China for Gemalto (and Trustonic) as liaison and evangelist of embedded Mobile Near-Field Communications Payments & TEE security technologies to the OEM Smartphone/Tablet PC ecosystem. Weaver has a B.S degree in Business Management from Salve Regina University and a Certification in Mandarin Chinese Language, Customs, and Culture from National Taiwan Normal University.

Links

A New Lithium-Metal Battery Takes Flight in Drones

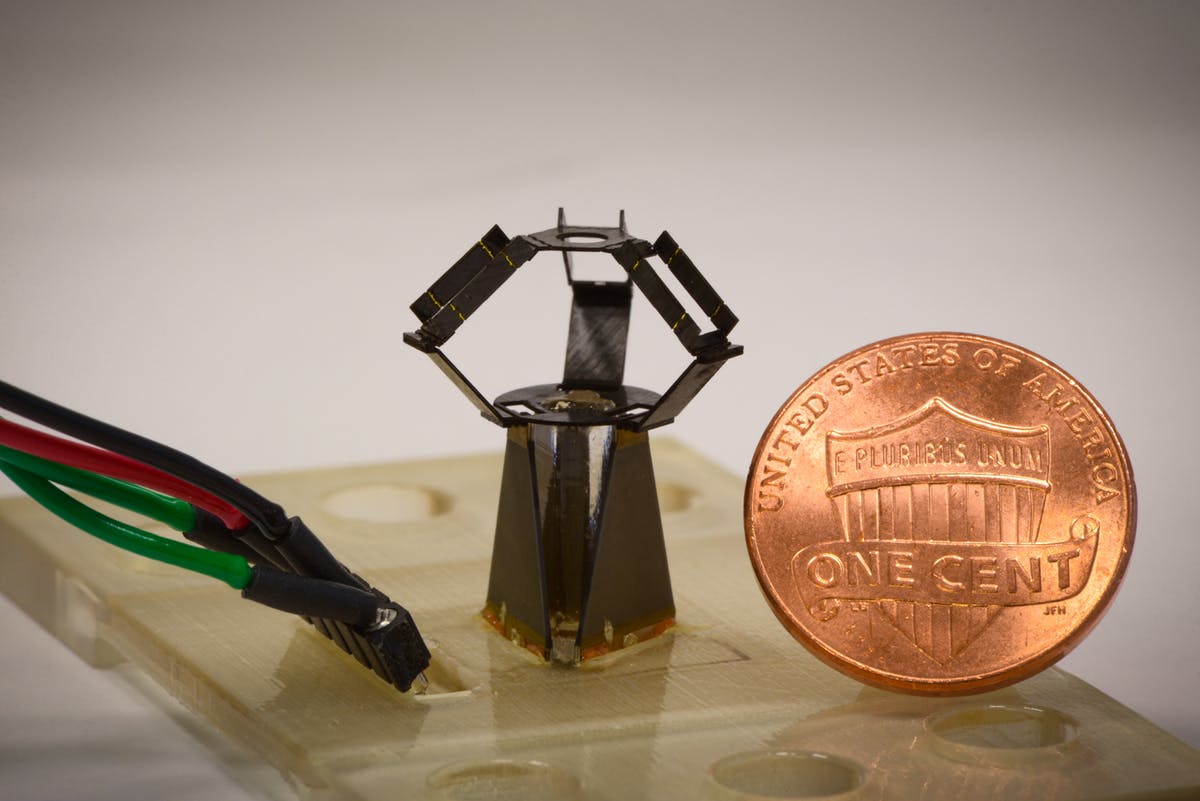

The millimeter-scale robot opens new avenues for microsurgery, microassembly and micromanipulation

By Benjamin Boettner

Because of their high precision and speed, Delta robots are deployed in many industrial processes, including pick-and-place assemblies, machining, welding and food packaging. Starting with the first version developed by Reymond Clavel for a chocolate factory to quickly place chocolate pralines in their packages, Delta robots use three individually controlled and lightweight arms that guide a platform to move fast and accurately in three directions. The platform is either used as a stage, similar to the ones being used in flight simulators, or coupled to a manipulating device that can, for example, grasp, move, and release objects in prescribed patterns. Over time, roboticists have designed smaller and smaller Delta robots for tasks in limited workspaces, yet shrinking them further to the millimeter scale with conventional manufacturing techniques and components has proven fruitless.

Reported in Science Robotics, a new design, the milliDelta robot, developed by Robert Wood’s team at Harvard’s Wyss Institute for Biologically Inspired Engineering and John A. Paulson School of Engineering and Applied Sciences (SEAS) overcomes this miniaturization challenge. By integrating their microfabrication technique with high-performance composite materials that can incorporate flexural joints and bending actuators, the milliDelta can operate with high speed, force, and micrometer precision, which make it compatible with a range of micromanipulation tasks in manufacturing and medicine.

In 2011, inspired by pop-up books and origami, Wood’s team developed a micro-fabrication approach that enables the assembly of robots from flat sheets of composite materials. Pop-up MEMS (short for “microelectromechanical systems”) manufacturing has since been used for the construction of dynamic centimeter-scale machines that can simply walk away, or, as in the case of the RoboBee, can fly. In their new study, the researchers applied their approach to develop a Delta robot measuring a mere 15 mm-by-15 mm-by-20 mm.

“The physics of scaling told us that bringing down the size of Delta robots would increase their speed and acceleration, and pop-up MEMS manufacturing with its ability to use any material or combination of materials seemed an ideal way to attack this problem,” said Wood, who is a Core Faculty member at the Wyss Institute and co-leader of its Bioinspired Robotics platform. Wood is also the Charles River Professor of Engineering and Applied Sciences at SEAS. “This approach also allowed us to rapidly go through a number of iterations that led us to the final milliDelta.”

The milliDelta design incorporates a composite laminate structure with embedded flexural joints that approximate the more complicated joints found in large scale Delta robots. “With the help of an assembly jig, this laminate can be precisely folded into a millimeter-scale Delta robot. The milliDelta also utilizes piezoelectric actuators, which allow it to perform movements at frequencies 15 to 20 times higher than those of other currently available Delta robots,” said first-author Hayley McClintock, a Wyss Institute Staff Researcher on Wood’s team.

In addition, the team demonstrated that the milliDelta can operate in a workspace of about seven cubic millimeters and that it can apply forces and exhibit trajectories that, together with its high frequencies, could make it ideal for micromanipulations in industrial pick-and-place processes and microscopic surgeries such as retinal microsurgeries performed on the human eye.

The work by Wood’s team demonstrating the enhanced speed and control of their milliDelta robot at the millimeter scale opens entirely new avenues of development for industrial and medical robots, which are currently beyond the reach of existing technologies. Donald Ingber

Putting the milliDelta’s potential for microsurgeries and other micromanipulations to a first test, the researchers explored their robot as a hand tremor-cancelling device. “We first mapped the paths that the tip of a toothpick circumscribed when held by an individual, computed those, and fed them into the milliDelta robot, which was able to match and cancel them out,” said co-first author Fatma Zeynep Temel, Ph.D., a SEAS Postdoctoral Fellow in Wood’s team. The researchers think that specialized milliDelta robots could either be added on to existing robotic devices, or be developed as standalone devices like, for example, platforms for the manipulation of cells in research and clinical laboratories.

“The work by Wood’s team demonstrating the enhanced speed and control of their milliDelta robot at the millimeter scale opens entirely new avenues of development for industrial and medical robots, which are currently beyond the reach of existing technologies. It’s yet another example of how our Bioinspired Robotics platform is leading the way into the future,” said Wyss Institute Founding Director Donald Ingber, M.D., Ph.D., who is also the Judah Folkman Professor of Vascular Biology at HMS and the Vascular Biology Program at Boston Children’s Hospital, as well as Professor of Bioengineering at SEAS.

Other authors on the study are Neel Doshi, a SEAS Graduate Student, and Je-sung Koh, Ph.D., a former Postdoctoral Fellow on Wood’s Wyss Institute/SEAS team and now Assistant Professor at Ajou University in Korea. The work was funded by Harvard’s Wyss Institute for Biologically Inspired Engineering and a National Defense Science and Engineering Graduate Fellowship.

Robots in Depth with Aseem Prakash

In this episode of Robots in Depth, Per Sjöborg speaks with Aseem Prakash, a Futurist at the Center for Innovating the Future, about how we can prepare for co-existing with robots and AI.

In this episode of Robots in Depth, Per Sjöborg speaks with Aseem Prakash, a Futurist at the Center for Innovating the Future, about how we can prepare for co-existing with robots and AI.

Robotic interiors

Courtesy of Ori

By Rob Matheson

Imagine living in a cramped studio apartment in a large city — but being able to summon your bed or closet through a mobile app, call forth your desk using voice command, or have everything retract at the push of a button.

MIT Media Lab spinout Ori aims to make that type of robotic living a reality. The Boston-based startup is selling smart robotic furniture that transforms into a bedroom, working or storage area, or large closet — or slides back against the wall — to optimize space in small apartments.

Based on years of Media Lab work, Ori’s system is an L-shaped unit installed on a track along a wall, so can slide back and forth. One side features a closet, a small fold-out desk, and several drawers and large cubbies. At the bottom is a pull-out bed. The other side of the unit includes a horizontal surface that can open out to form a table. The vertical surface above that features a large nook where a television can be placed, and additional drawers and cubbies. The third side, opposite the wall, contains still more shelving, and pegs to hang coats and other items.

Users control the unit through a control hub plugged into a wall, or through Ori’s mobile app or a smart home system, such as Amazon’s Echo.

Essentially, a small studio can at any time become a bedroom, lounge, walk-in closet, or living and working area, says Ori founder and CEO Hasier Larrea SM ’15. “We use robotics to … make small spaces act like they were two or three times bigger,” he says. “Around 200 square feet seems too small [total area] to live in, but a 200-square-foot bedroom or living room doesn’t seem so small.” Larrea was named to Forbes’ 2017 30 Under 30 list for his work with Ori.

The first commercial line of the systems, which goes for about $10,000, is now being sold to real estate developers in Boston and other major cities across the U.S. and Canada, for newly built or available apartments. In Boston, partners include Skanska, which has apartments in the Seaport; Samuels and Associates, with buildings around Harvard Square; and Hines for its Marina Bay units. Someday, Larrea says, the system could be bought directly by consumers.

Once the system catches on and the technology evolves, Larrea imagines future apartments could be furnished entirely with robotic furniture from Ori and other companies.

“These technologies can evolve for kitchens, bathrooms, and general partition walls. At some point, a two-bedroom apartment could turn into a large studio, transform into three rooms for your startup, or go into ‘party mode,’ where it all opens up again,” Larrea says. “Spaces will adapt to us, instead of us adapting to spaces, which is what we’ve been doing for so many years.”

Architectural robotics

In 2011, Larrea joined the Media Lab’s City Science research group, directed by Principal Research Scientist Kent Larson, which included his three co-founders: Chad Bean ’14, Carlos Rubio ’14, and Ivan Fernandez de Casadevante, who was a visiting researcher.

The group’s primary focus was tackling challenges of mass urbanization, as cities are becoming increasingly popular living destinations. “Data tells us that, in places like China and India, 600 million people will move from towns to cities in the next 15 years,” Larrea says. “Not only is the way we move through cities and feed people going to need to evolve, but so will the way people live and work in spaces.”

A second emerging phenomenon was the Internet of Things, which saw an influx of smart gadgets, including household items and furniture, designed to connect to the Internet. “Those two megatrends were bound to converge,” Larrea says.

The group started a project called CityHome, creating what it called “architectural robotics,” which integrated robotics, architecture, computer science, and engineering to design smart, modular furniture. The group prototyped a moveable wall that could be controlled via gesture control — which looked similar to today’s Ori system — and constructed a mock 200-square-foot studio apartment on the fifth floor of the Media Lab to test it out. Within the group, the unit was called “furniture with superpowers,” Larrea says, as it made small spaces seem bigger.

After they had constructed their working prototype, in early 2015 the researchers wanted to scale up. Inspiration came from the Media Lab-LEGO MindStorms collaboration from the late 1990s, where researchers created kits that incorporated sensors and motors inside traditional LEGO bricks so kids could build robots and researchers could prototype.

Drawing from that concept, the group built standardized components that could be assembled into a larger piece of modular furniture — what Ori now calls the robotic “muscle,” “skeleton,” “brains,” and the furniture “skins.” Specifically, the muscle consists of the track, motors, and electronics that actuate the system. The skeleton is the frame and the wheels that give the unit structure and movement. The brain is the microcomputer that controls all the safety features and connects the device to the Internet. And the skin is the various pieces of furniture that can be integrated, using the same robotic architecture.

Today, units fit full- or queen-size mattresses and come in different colors. In the future, however, any type of furniture could be integrated, creating units of various shapes, sizes, uses, and price. “The robotics will keep evolving but stay standardized … so, by adding different skins, you can really create anything you can imagine,” Larrea says.

Kickstarting Ori

Going through the Martin Trust Center for MIT Entrepreneurship’s summer accelerator delta V (then called the Global Founders Skills Accelerator) in 2015 “kickstarted” the startup, Larrea says. One lesson that particularly stood out: the importance of conducting market research. “At MIT, sometimes we assume, because we have such a cool technology, marketing it will be easy. … But we forget to talk to people,” he says.

In the early days, the co-founders put tech development aside to speak with owners of studios, offices, and hotels, as well as tenants. In doing so, they learned studio renters in particular had three major complaints: Couples wanted separate living areas, and everyone wanted walk-in closets and space to host parties. The startup then focused on developing a furniture unit that addressed those issues.

After earning one of its first investors in the Media Lab’s E14 Fund in fall 2015, the startup installed an early version of its system in several Boston apartments for renters to test and provide feedback. Soon after, the system hit apartments in 10 major cities across the U.S. and Canada, including San Francisco, Vancouver, Chicago, Miami, and New York. Over the past two years, the startup has used feedback from those pilots to refine the system into today’s commercial model.

Ori will ship an initial production run of 500 units for apartments over the next few months. Soon, Larrea says, the startup also aims to penetrate adjacent markets, such as hotels, dormitories, and offices. “The idea is to prove this isn’t a one-trick pony,” Larrea says. “It’s part of a more comprehensive strategy to unlock the potential of space.”

Robotics industry fundings, acquisitions & IPOs: January 2018

Twenty-five different startups were funded in January cumulatively raising $784 million; a great start for the new year. Four acquisitions were reported during the month while the IPO front lay waiting for something to happen.

According to Silicon Valley Bank’s annual survey of 1,000+ executives, startup founders are confident 2018 will be a good year for funding and for business conditions – except hiring and retaining foreign talent.

More than half of startups surveyed (51%) reported that at least one of their founders is an immigrant. One-third of startups said laws and regulations prompted them to locate facilities (or move non-sales operations) offshore. U.S. immigration policy was cited as being the biggest driver, followed by tax policies and the regulatory environment.

An interesting aside in the bank’s Chinese version of the survey is that about 2/3 of Chinese startups have at least one woman in a senior role, a considerably higher percentage than in the US where 71% of startups have no women on their board of directors and only 43% have women in executive positions.

Fundings

1. Carbon 3D, a 2013 Silicon Valley 3D manufacturing startup using elastomers and carbon steel, raised $200 million for a Series D funding led by Johnson & Johnson Innovation. Other funders included Baillie Gifford, Fidelity Management & Research Company ARCHINA Capital, Hydra Ventures (the corporate venturing arm of Adidas), GE Ventures, JSR Corporation, and Emerson Elemental. The funding is also supported by current investors including BMW Ventures, Sequoia Capital, Silver Lake Kraftwerk, and Reinet Investments and others.

2. Pony.ai, a Fremont, Calif. and China-based self-driving startup, raised $112 million in Series A funding. Morningside Venture Capital and Legend Capital led the round, and were joined by investors including Sequoia China, IDG Capital, Hongtai Capital, Legend Star, Puhua Capital, Polaris Capital, DCM Ventures, Comcast Ventures and Silicon Valley Future Capital.

3. Rokid, a Chinese and Silicon Valley developer of award-winning consumer products rivaling Amazon’s Echo (in China), raised $100 million in a Series C round from Temasek Holdings with participation from Credit Suisse, IDG Capital Partners and CDIB Capital.

4. Nuro, a Silicon Valley startup developing a self-driving delivery vehicle, raised $92 million in a Series A funding led by Banyan Capital and Greylock Partners plus individual investor Simon Rothman.

5. Precision Hawk, a Raleigh, NC provider of drone technology and analytics, raised $75 million in funding. Third Point Ventures led the round, and was joined by investors including Comcast Ventures, Senator Investor Group, Constellation Technology Ventures andSyngenta Ventures. Existing investors Intel Capital, Millennium Technology Value Partners, DuPont, Verizon Ventures, and Indiana University’s Innovate Indiana Fund participated.

6. AImotive, a Hungarian startup offering full-stack autonomous vehicle technology, raised $38 million in Series C funding. B Capital Group and Prime Ventures led the round, and was joined by investors including Cisco Investments, Samsung Catalyst Fund, and Series A and B investors Robert Bosch Venture Capital, Inventure, Draper Associates and Day One Capital.

7. Knightscope, a Mountain View, Calif.-based maker of security robots, raised more than $25 million in funding. Investors include Konica Minolta and Bright Success Capital.

8. EasyMile, a French self-driving systems startup with tests running in Finland, Greece, France and Switzerland, raised around $17.4 million in a Series A round funded by Alstom.

9. Occipital, a Boulder, Colo.-based developer of mobile computer vision applications, raised $15 million in Series C funding, according to TechCrunch. Foundry Group led the round. With this round, Occipital is looking to expand its tracking platform into what it calls its “Perception Engine,” which will require it making some deeper moves into machine learning, pushing into technologies that reside outside of simply defining the geometry of a space. The startup wants its tracking tech to recognize people and identify objects.

10. Voyage, a Silicon Valley autonomous taxi service, raised $15 million from led by InMotion Ventures with additional funds from SV Angel, Khosla Ventures, Initialized Capital, CRV and Amino Capital. Voyage recently announced plans to deploy a fleet of AV taxis in a 125k resident retirement community in Florida.

11. Huazhi IMT, a Chinese industrial robot integrator, received $15 million in early stage funding from Ying Capital and Banyan Capital.

12. Canvas Technology, a Boulder, CO startup building mobile robots for warehouses, raised $15 million in a Series A round led by Playground Global, with previous investors Xplorer Capital, AME Cloud Ventures and Morado Ventures.

13. Mall Parking, a Shenzhen mobile parking system developer, raised $12.5 million in Series B funding from the Holdfound Group.

14. Robotis Dynamixel, a Korean maker of actuators, parts and educational robot kits, raised $8.5 million from LG Electronics for a 10.12% share of the company.

15. Beijing Aqiu Technology (Aqrose), a Chinese start-up that applies machine vision and machine learning technology into industrial automation, raised $8 million in a series A round led by Baidu Ventures and DCM China with participation by Long Capital, Powercloud Venture Capital and Innoangel Fund.

16. Iris Automation, a San Francisco-based provider of collision avoidance for commercial drones, raised $8 million in Series A funding led by Bessemer Venture Partners and including Bee Partners.

17. SkySpecs, an Ann Arbor, Michigan-based automated infrastructure inspection company, raised $8 million in Series B funding. Investors include Statkraft Ventures, UL Ventures, Capital Midwest, Venture Investors, and Huron River Ventures.

18. CalmCar Vehicle Vision, a Chinese driving vision system provider, raised $4.6 million from Shenzhen Guozhong Venture Capital Management.

19. Doxel, a Silicon Valley construction productivity startup using AI and vision systems, raised $4.5 million in a round led by Andreessen Horowitz with participation by Alchemist Accelerator, Pear Ventures, SV Angel and Steelhead Ventures participating. Doxel uses autonomous devices to monitor a site every day, with LIDAR and HD cameras. Their AI then processes this visual data, inspects installation quality, and quantifies how much material has been installed correctly and then provide real-time feedback on productivity.

20. Altitude Angel, a UK startup providing a drone traffic management platform and airspace integration system, raised $4.5 million in Series A funding led by Seraphim Space Fund with participation from ADV and Frequentis AG.

21. Iron Ox, a San Francisco, Calif.-based developer of robots for crop harvesting, raised $3 million in seed funding. Eniac Ventures led the round, and was joined by investors including Amplify Partners.

22. Understand.ai, a machine-learning startup for training and validation data in autonomous vehicles, raised $2.8 million in seed funding. LEA Partners led the round, and was joined by investors including Frontline Ventures, Synapse Partners and Agile Partners.

23. Converge Industries, a San Francisco-based startup providing AI powered software for commercial drones for insurance adjusters, raised $750k in a seed round led by Samsung’s NEXT Ventures, Techstars and Kima Ventures with participation from Right Side Capital Management.

24. Maidbot, an Austin, TX industrial cleaning robot startup, received an undisclosed amount in an A round led by Bissell with participation from existing and new investors including 1517 Fund, Comet Labs, and Rough Draft Ventures, along with strategic hospitality and industrial cleaning organizations.

25. Connexient, a New York City-based provider of indoor mapping, navigation and location-based services for companies with large, complex buildings and campuses raised an undisclosed amount of funding from Riverside Acceleration Capital.

Acquisitions

1. Uber sold a 15% stake to SoftBank for $7.75 billion. $6.5 billion of the SoftBank investment was at a 30% discount against Uber’s private valuation of $69 billion. The additional $1.25 billion was at Uber’s current/higher valuation. That’s a major deal at a significant discount for SoftBank.

2. Key Technology, a Walla Walla, WA-based industrial robots integrator, was acquired by Duravant, a food processing equipment solutions provider, for $175 million. Duravent issued a tender offer to acquire all of the outstanding shares of Key common stock at $26.75 per share ($175 million).

3. PaR Systems, a Minnesota-based integrator of industrial robotics and also engineering services for mission-critical special situations, was acquired by the Pohlad family (which also owns the Minnesota Twins baseball team. PaR has 380 employees. Financial details were not disclosed. Pohlad bought PaR from MML Capital Partners, an equity fund.

4. Visual Components, a Finnish software and AI company providing 3D simulation software to manufacturers including Kuka, Foxconn and Samsung, was acquired by Kuka.

IPOs

Nada. Zip. Nothing. In the SV Bank survey referenced above, executives were asked what their realistic long-term goal and/or exit plan was and 57% responded they thought that acquisition was the most common path for them. Only 18% said they would go public.

3Q: Daron Acemoglu on technology and the future of work

Photo: Jared Charney

By Meg Murphy

K. Daron Acemoglu, the Elizabeth and James Killian Professor of Economics at MIT, is a leading thinker on the labor market implications of artificial intelligence, robotics, automation, and new technologies. His innovative work challenges the way people think about these technologies intersect with the world of work. In 2005, he won the John Bates Clark Medal, an honor shared by a number of Nobel Prize recipients and luminaries in the field of economics.

Acemoglu holds a bachelor’s degree in economics from University of York. His master’s degree in mathematical economics and econometrics and doctorate in economics are from the London School of Economics. With political scientist James Robinson, Acemoglu co-authored the much discussed book “Why Nations Fail” (Crown Business, 2012) and “Economic Origins of Dictatorship and Democracy” (Cambridge University Press, 2006). He also wrote the book, “Introduction to Modern Economic Growth” (Princeton University Press, 2008). Acemoglu recently answered a few questions about technology and work.

Q: How do we begin to understand the rise of artificial intelligence and its future impact on society?

A: We need to look to the past in the face of modern innovations in machine learning, robotics, artificial intelligence, big data, and beyond. The process of machines replacing labor in the production process is not a new one. It’s been going on pretty much continuously since the Industrial Revolution. Spinning and weaving machines took jobs away from spinners and weavers. One innovation would follow another, and people would be thrown out of work by a machine performing the job in a cheaper way.

But at the end of the day, the Industrial Revolution and its aftermath created much better opportunities for people. For much of the 20th century in the U.S., workers’ wages and employment kept growing. New occupations and new tasks and new jobs were generated within the framework of new technological knowledge. A huge number of occupations in the American economy today did not exist 50 years ago — radiologists, management consultants, software developers, and so on. Go back a century and most of the white-collar jobs today did not exist.

Q: Do you think public fears about the future of work are just?

A: The way we live continuously changes in significant ways — how we learn, how we acquire food, what we emphasize, our social organizations.

Our adjustments to technology — especially transformative technologies — are not a walk in the park. It is not going to be easy and seamless and just sort itself out. A lot of historical evidence shows the process is a painful one. The mechanization of agriculture is one of the greatest achievement of the American economy but it was hugely disruptive for millions of people who suffered joblessness.

At the same time, we are capable technologically and socially of creating many new jobs that will take people to new horizons in terms of productivity and freedom from the hardest types of manual labor. There are great opportunities with artificial intelligence but whether or not we exploit them is a different question. I think you should never be too optimistic but neither should you be too pessimistic.

Q: How do you suggest people prepare for the future job market?

A: We are very much in the midst of understanding what sort of process we are going through. We don’t even necessarily know what skills are needed for the jobs of the future.

Imagine one scenario. Artificial intelligence removes the need for seasoned accountants to fulfill numeracy-related tasks. But we need tax professionals, for instance, to inform clients about their choices and options in some sort of emphatic human way. They will have to become the interface between the machines and the customers. The jobs of the future, in this instance and many others, would require communications, flexibility, and social skills.

However, I don’t know if my hypothesis is true because we haven’t tested it. We haven’t lived through it. I see the biggest void in our knowledge. People at institutions like MIT must learn more about what’s is going on so that we are better prepared to understand the future.

How A Formerly Struggling AgTech Provider Dominated An Industry Sector, In 3 Steps

OptoForce Industrial Robot Sensors

OptoForce Sensors Providing Industrial Robots with

a “Sense of Touch” to Advance Manufacturing Automation

Global efforts to expand the capabilities of industrial robots are on the rise, as the demand from manufacturing companies to strengthen their operations and improve performance grows.

Hungary-based OptoForce, with a North American office in Charlotte, North Carolina, is one company that continues to support organizations with new robotic capabilities, as evidenced by its several new applications released in 2017.

The company, a leading robotics technology provider of multi-axis force and torque sensors, delivers 6 degrees of freedom force and torque measurement for industrial automation, and provides sensors for most of the currently-used industrial robots.

It recently developed and brought to market three new applications for KUKA industrial robots.

The new applications are hand guiding, presence detection, and center pointing and will be utilized by both end users and systems integrators. Each application is summarized below and what they provide for KUKA robots, along with video demonstrations to show how they operate.

- Hand Guiding: With OptoForce’s Hand Guiding application, KUKA robots can easily and smoothly move in an assigned direction and selected route. This video shows specifically how to program the robot for hand guiding.

- Presence Detection: This application allows KUKA robots to detect the presence of a specific object and to find the object even if it has moved. Visit here to learn more about presence detection.

- Center Pointing: With this application, the OptoForce sensor helps the KUKA robot find the center point of an object by providing the robot with a sense of touch. This solution also works with glossy metal objects where a vision system would not be able to define its position. This video shows in detail how the center pointing application works.

The company’s CEO explained how these applications help KUKA robots and industrial automation.

“OptoForce’s new applications for KUKA robots pave the way for substantial improvements in industrial automation for both end users and systems integrators,” said Ákos Dömötör, CEO of OptoForce. “Our 6-axis force/torque sensors are combined with highly functional hardware and a comprehensive software package, which include the pre-programmed industrial applications. Essentially, we’re adding a ‘sense of touch’ to KUKA robot arms, enabling these robots to have abilities similar to a human hand, and opening up numerous new capabilities in industrial automation.”

Along with these new applications recently released for KUKA robots, OptoForce sensors are also being used by various companies on numerous industrial robots and manufacturing automation projects around the world. Examples of other uses include: path recording, polishing plastic and metal, box insertion, placing pins in holes, stacking/destacking, palletizing, and metal part sanding.

Specifically, some of the projects current underway by companies include: a plastic parting line removal; an obstacle detection for a major car manufacturing company; and a center point insertion application for a car part supplier, where the task of the robot is to insert a mirror, completely centered, onto a side mirror housing.

For more information, visit www.optoforce.com.

This post was provided by: OptoForce

The post OptoForce Industrial Robot Sensors appeared first on Roboticmagazine.