Intuitive physics learning in a deep-learning model inspired by developmental psychology

Intuitive physics learning in a deep-learning model inspired by developmental psychology

Robot sales surge in Europe, Asia and the Americas

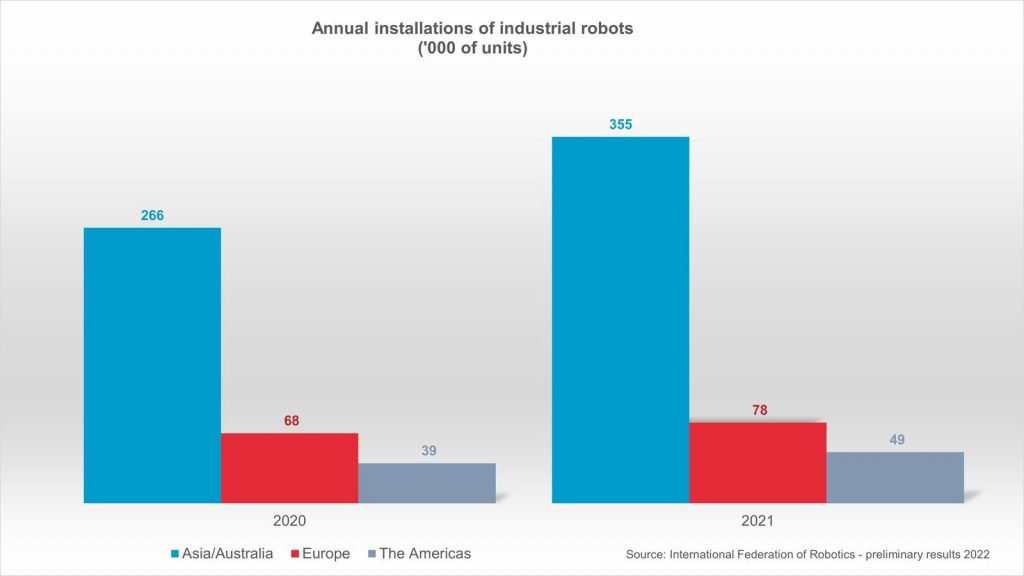

Sales of industrial robots have reached a strong recovery: A new record of 486,800 units were shipped globally – an increase of 27% compared to the previous year. Asia/Australia saw the largest growth in demand: installations were up 33% reaching 354,500 units. The Americas increased by 27% with 49,400 units sold. Europe saw double digit growth of 15% with 78,000 units installed. These preliminary results for 2021 have been published by the International Federation of Robotics.

Preliminary annual installations 2022 compared to 2020 by region – source: International Federation of Robotics

“Robot installations around the world recovered strongly and make 2021 the most successful year ever for the robotics industry,” says Milton Guerry, President of the International Federation of Robotics (IFR). “Due to the ongoing trend towards automation and continued technological innovation, demand reached high levels across industries. In 2021, even the pre-pandemic record of 422,000 installations per year in 2018 was exceeded.”

Strong demand across industries

In 2021, the main growth driver was the electronics industry (132,000 installations, +21%), which surpassed the automotive industry (109,000 installations, +37%) as the largest customer of industrial robots already in 2020. Metal and machinery (57,000 installations, +38%) followed, ahead of plastics and chemical products (22,500 installations, +21%) and food and beverages (15,300 installations, +24%).

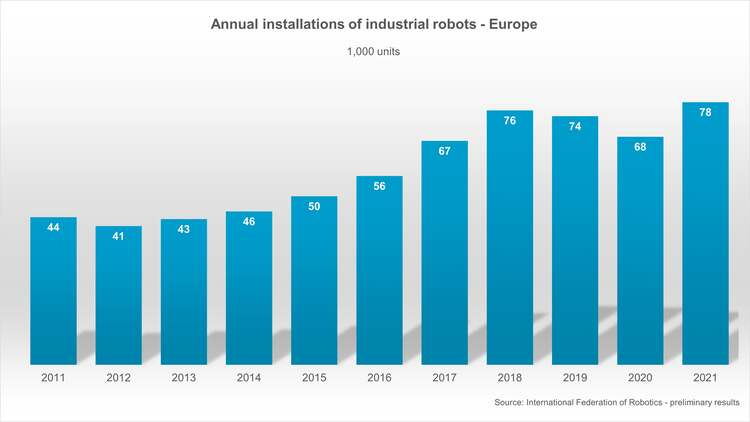

Europe recovered

In 2021, industrial robot installations in Europe recovered after two years of decline – exceeding the peak of 75,600 units in 2018. Demand from the most important adopter, the automotive industry, moved at a high level sideways (19,300 installations, +/-0%). Demand from metal and machinery rose strongly (15,500 installations, +50%), followed by plastics and chemical products (7,700 installations, +30%).

The Americas recovered

In the Americas, the number of industrial robot installations reached the second-best result ever, only surpassed by the record year 2018 (55,200 installations). The largest American market, the United States, shipped 33,800 units – this represents a market share of 68%.

Asia remains world’s largest market

Asia remains the world’s largest industrial robot market: 73% of all newly deployed robots in 2021 were installed in Asia. A total of 354,500 units were shipped in 2021, up 33% compared to 2020. The electronics industry adopted by far the most units (123,800 installations, +22%), followed by a strong demand from the automotive industry (72,600 installations, +57%) and the metal and machinery industry (36,400 installations, +29%).

Video: “Sustainable! How robots enable a green future”

At automatica 2022 trade fair in Munich, robotics industry leaders discussed, how robotics and automation enable to develop sustainable strategies and a green future. A videocast by IFR will feature the event with key statements of executives from ABB, MERCEDES BENZ, STÄUBLI, VDMA and the EUROPEAN COMMISSION. Please find a summary soon on our YouTube Channel.

Responsive soft robots inspired by sputtering ketchup bottle

Industrial Robots Push Into New Applications and Industries

What robots can learn from therapists

Robotic lightning bugs take flight

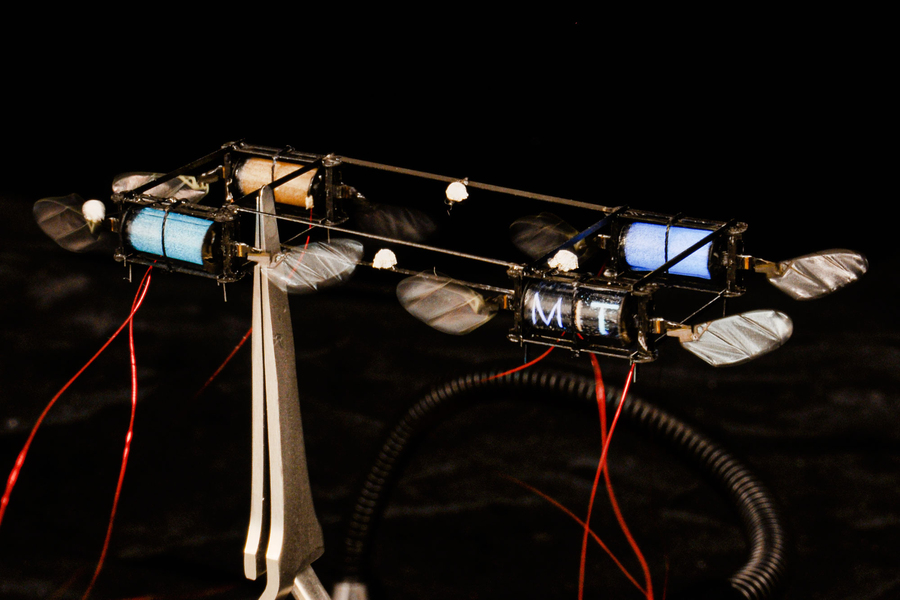

Inspired by fireflies, MIT researchers have created soft actuators that can emit light in different colors or patterns. Credits: Courtesy of the researchers

By Adam Zewe | MIT News Office

Fireflies that light up dusky backyards on warm summer evenings use their luminescence for communication — to attract a mate, ward off predators, or lure prey.

These glimmering bugs also sparked the inspiration of scientists at MIT. Taking a cue from nature, they built electroluminescent soft artificial muscles for flying, insect-scale robots. The tiny artificial muscles that control the robots’ wings emit colored light during flight.

This electroluminescence could enable the robots to communicate with each other. If sent on a search-and-rescue mission into a collapsed building, for instance, a robot that finds survivors could use lights to signal others and call for help.

The ability to emit light also brings these microscale robots, which weigh barely more than a paper clip, one step closer to flying on their own outside the lab. These robots are so lightweight that they can’t carry sensors, so researchers must track them using bulky infrared cameras that don’t work well outdoors. Now, they’ve shown that they can track the robots precisely using the light they emit and just three smartphone cameras.

“If you think of large-scale robots, they can communicate using a lot of different tools — Bluetooth, wireless, all those sorts of things. But for a tiny, power-constrained robot, we are forced to think about new modes of communication. This is a major step toward flying these robots in outdoor environments where we don’t have a well-tuned, state-of-the-art motion tracking system,” says Kevin Chen, who is the D. Reid Weedon, Jr. Assistant Professor in the Department of Electrical Engineering and Computer Science (EECS), the head of the Soft and Micro Robotics Laboratory in the Research Laboratory of Electronics (RLE), and the senior author of the paper.

He and his collaborators accomplished this by embedding miniscule electroluminescent particles into the artificial muscles. The process adds just 2.5 percent more weight without impacting the flight performance of the robot.

Joining Chen on the paper are EECS graduate students Suhan Kim, the lead author, and Yi-Hsuan Hsiao; Yu Fan Chen SM ’14, PhD ’17; and Jie Mao, an associate professor at Ningxia University. The research was published this month in IEEE Robotics and Automation Letters.

A light-up actuator

These researchers previously demonstrated a new fabrication technique to build soft actuators, or artificial muscles, that flap the wings of the robot. These durable actuators are made by alternating ultrathin layers of elastomer and carbon nanotube electrode in a stack and then rolling it into a squishy cylinder. When a voltage is applied to that cylinder, the electrodes squeeze the elastomer, and the mechanical strain flaps the wing.

To fabricate a glowing actuator, the team incorporated electroluminescent zinc sulphate particles into the elastomer but had to overcome several challenges along the way.

First, the researchers had to create an electrode that would not block light. They built it using highly transparent carbon nanotubes, which are only a few nanometers thick and enable light to pass through.

However, the zinc particles only light up in the presence of a very strong and high-frequency electric field. This electric field excites the electrons in the zinc particles, which then emit subatomic particles of light known as photons. The researchers use high voltage to create a strong electric field in the soft actuator, and then drive the robot at a high frequency, which enables the particles to light up brightly.

“Traditionally, electroluminescent materials are very energetically costly, but in a sense, we get that electroluminescence for free because we just use the electric field at the frequency we need for flying. We don’t need new actuation, new wires, or anything. It only takes about 3 percent more energy to shine out light,” Kevin Chen says.

As they prototyped the actuator, they found that adding zinc particles reduced its quality, causing it to break down more easily. To get around this, Kim mixed zinc particles into the top elastomer layer only. He made that layer a few micrometers thicker to accommodate for any reduction in output power.

While this made the actuator 2.5 percent heavier, it emitted light without impacting flight performance.

“We put a lot of care into maintaining the quality of the elastomer layers between the electrodes. Adding these particles was almost like adding dust to our elastomer layer. It took many different approaches and a lot of testing, but we came up with a way to ensure the quality of the actuator,” Kim says.

Adjusting the chemical combination of the zinc particles changes the light color. The researchers made green, orange, and blue particles for the actuators they built; each actuator shines one solid color.

They also tweaked the fabrication process so the actuators could emit multicolored and patterned light. The researchers placed a tiny mask over the top layer, added zinc particles, then cured the actuator. They repeated this process three times with different masks and colored particles to create a light pattern that spelled M-I-T.

These artificial muscles, which control the wings of featherweight flying robots, light up while the robot is in flight, which provides a low-cost way to track the robots and also could enable them to communicate. Credits: Courtesy of the researchers

Following the fireflies

Once they had finetuned the fabrication process, they tested the mechanical properties of the actuators and used a luminescence meter to measure the intensity of the light.

From there, they ran flight tests using a specially designed motion-tracking system. Each electroluminescent actuator served as an active marker that could be tracked using iPhone cameras. The cameras detect each light color, and a computer program they developed tracks the position and attitude of the robots to within 2 millimeters of state-of-the-art infrared motion capture systems.

“We are very proud of how good the tracking result is, compared to the state-of-the-art. We were using cheap hardware, compared to the tens of thousands of dollars these large motion-tracking systems cost, and the tracking results were very close,” Kevin Chen says.

In the future, they plan to enhance that motion tracking system so it can track robots in real-time. The team is working to incorporate control signals so the robots could turn their light on and off during flight and communicate more like real fireflies. They are also studying how electroluminescence could even improve some properties of these soft artificial muscles, Kevin Chen says.

“This work is really interesting because it minimizes the overhead (weight and power) for light generation without compromising flight performance,” says Kaushik Jayaram, an assistant professor in Department of Mechanical Engineering at the University of Colorado at Boulder, who was not involved with this research. “The wingbeat synchronized flash generation demonstrated in this work will make it easier for motion tracking and flight control of multiple microrobots in low-light environments both indoors and outdoors.”

“While the light production, the reminiscence of biological fireflies, and the potential use of communication presented in this work are extremely interesting, I believe the true momentum is that this latest development could turn out to be a milestone toward the demonstration of these robots outside controlled laboratory conditions,” adds Pakpong Chirarattananon, an associate professor in the Department of Biomedical Engineering at the City University of Hong Kong, who also was not involved with this work. “The illuminated actuators potentially act as active markers for external cameras to provide real-time feedback for flight stabilization to replace the current motion capture system. The electroluminescence would allow less sophisticated equipment to be used and the robots to be tracked from distance, perhaps via another larger mobile robot, for real-world deployment. That would be a remarkable breakthrough. I would be thrilled to see what the authors accomplish next.”

This work was supported by the Research Laboratory of Electronics at MIT.

A drone that can avoid obstacles helped win a sweeping new approval for aerial inspections of power facilities

Human-like robots may be perceived as having mental states

World’s Largest Pasta Production Plant a Showcase for Integrated Robotics and Sustainable Distribution

Bees’ ‘waggle dance’ may revolutionize how robots talk to each other in disaster zones

5 Amazing Benefits of Combining AR, VR and Robotics

The next frontier for drones: letting them fly out of sight

Dan Mantz: Growing Interest in STEM, Soft Skills, and Labor Shortages | Sense Think Act Podcast #21

In this episode, Audrow Nash speaks to Dan Mantz, who is the CEO of the Robotics Education and Competition (REC) Foundation. The REC Foundation is a nonprofit that works with VEX Robotics to build interest in STEM related career opportunities. Dan speaks about the different competitions REC facilitates, why REC is a nonprofit, how REC works with VEX Robotics, on the importance of soft skills, on workforce gaps, and on the future of education.

Episode Links

Podcast info