Autonomous aerial and ground-based robots to protect critical infrastructure

Embracing Automation Technologies to Optimise Just-in-Time Processes

Embracing Automation Technologies to Optimise Just-in-Time Processes

Could artificial intelligence help us build a technological world that is more ethical?

A gyroscope-free system to efficiently control the flight of insect-size robots

Mapping the Stars, Galaxies and Black Holes in the Universe, Thanks to Precision of Faulhaber Motors & Systems

New ABB SWIFTI industrial cobot delivers class-leading speed, accuracy and safety

A Guide To Stay Safe When Playing At An Online Casino

Online gambling is one of the most popular activities among the American people. With its growing popularity and legalization, more people are joining the world of online gambling. States such as Delaware have legalized online casinos. Online Casino DE offers a complete guide for players in the state. When it comes to online gambling, safety should...

The post <strong>A Guide To Stay Safe When Playing At An Online Casino</strong> appeared first on 1redDrop.

Featured video: Creating a sense of feeling

Shriya Srinivasan as a dancer and researcher | Snapshots taken from ‘Connecting the human body to the outside world’ video on YouTube

“The human body is just engineered so beautifully,” says Shriya Srinivasan PhD ’20, a research affiliate at MIT’s Koch Institute for Integrative Cancer Research, a junior fellow at the Society of Fellows at Harvard University, and former doctoral student in the Harvard-MIT Program in Health Sciences and Technology.

Both a biomedical engineer and a dancer, Srinivasan is dedicated to investigating the body’s movements and sensations. As a PhD student she worked in Media Lab Professor Hugh Herr’s Biomechatronics Group on a system that helps patients with amputation feel what their prostheses are feeling and send feedback from the device to the body. She has also studied the south Indian classical dance form Bharathanatyam for 22 years and co-directs the Anubhava Dance Company.

“The kind of relief and sense of fulfillment I get from the arts is very different from what I get from research and science,” she says. “I find that research often nourishes my intellectual curiosity, and the arts are helping to build that emotional and spiritual growth. But in both worlds, I’m thinking about how we create a sense of feeling, how we control emotion and your physiological response. That’s really beautiful to me.”

Video by: Jason Kimball/MIT News | 5 minutes 34 seconds.

China overtakes USA in robot density, according to World Robotics 2022 Report

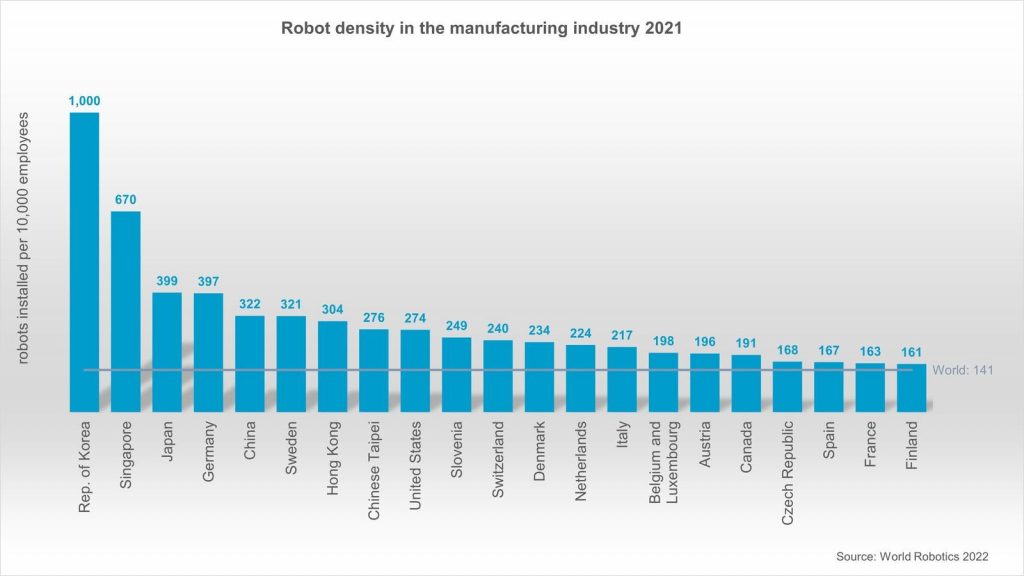

China’s massive investment in industrial robotics has put the country in the top ranking of robot density, surpassing the United States for the first time. The number of operational industrial robots relative to the number of workers hit 322 units per 10,000 employees in the manufacturing industry. Today, China ranks in fifth place. The world´s top 5 most automated countries in manufacturing 2021 are: South Korea, Singapore, Japan, Germany and China.

World average of robot density more than doubles compared to six years ago (2015: 69 units)

“Robot density is a key indicator of automation adoption in the manufacturing industry around the world,” says Marina Bill, President of the International Federation of Robotics. “The new average of global robot density in the manufacturing industry surged to 141 robots per 10,000 employees – more than double the number six years ago. China’s rapid growth shows the power of its investment so far, but it still has much opportunity to automate.”

Robot density by region

Driven by the high volume of robot installations in recent years, Asia’s average robot density surged by 18% compound annual growth rate (CAGR) since 2016 to 156 units per 10,000 employees in 2021. The European robot density had been growing by 8% (CAGR) in the same period of time reaching 129 units. In the Americas it was 117 robots – plus 8% (CAGR).

Top countries

The Republic of Korea hit an all-time high of 1,000 industrial robots per 10,000 employees in 2021. This is more than three times the number reached in China and makes the country number one worldwide. With its globally recognized electronics industry and a distinct automotive sector, the Korean economy profits from two large customer industries for industrial robots.

Singapore takes second place with a rate of 670 robots per 10,000 employees in 2021. Singapore’s robot density had been growing by 24% on average each year since 2016.

There is a remarkable gap to Japan (399 robots per 10,000 employees) which ranks third. Japan’s robot density had grown by 6% on average each year since 2016. Germany in fourth place (397 units) is the largest robot market in Europe.

China is by far the fastest growing robot market in the world. The country has the highest number of annual installations, and since 2016 it has each year had the largest operational stock of robots.

United States

Robot density in the United States rose from 255 units in 2020 to 274 units in 2021. The country ranks ninth in the world, down from seventh – now head-to-head with Chinese Taipei (276 units) and behind Hong Kong (304 units) and Sweden (321 units).

Orders for World Robotics 2022 Service Robots and Industrial Robots reports can be placed online. Further downloads on the content are available here.

Videos

FACTS video about ROBOT DENSITY

Video of recorded World Robotics press conference

KPI INTEGRATED SOLUTIONS OPENS FIRST FULL-SCALE DEMONSTRATION SITE IN NORTH AMERICA FOR NEW GEEK+ FOUR-WAY SHUTTLE SOLUTION

MiniMACS6 Stabilizes the Furuta Pendulum

Looking beyond “technology for technology’s sake”

“Learning about the social implications of the technology you’re working on is really important,” says senior Austen Roberson. Photo: Jodi Hilton

By Laura Rosado | MIT News correspondent

Austen Roberson’s favorite class at MIT is 2.S007 (Design and Manufacturing I-Autonomous Machines), in which students design, build, and program a fully autonomous robot to accomplish tasks laid out on a themed game board.

“The best thing about that class is everyone had a different idea,” says Roberson. “We all had the same game board and the same instructions given to us, but the robots that came out of people’s minds were so different.”

The game board was Mars-themed, with a model shuttle that could be lifted to score points. Roberson’s robot, nicknamed Tank Evans after a character from the movie “Surf’s Up,” employed a clever strategy to accomplish this task. Instead of spinning the gears that would raise the entire mechanism, Roberson realized a claw gripper could wrap around the outside of the shuttle and lift it manually.

“That wasn’t the intended way,” says Roberson, but his outside-of-the-box strategy ending up winning him the competition at the conclusion of the class, which was part of the New Engineering Education Transformation (NEET) program. “It was a really great class for me. I get a lot of gratification out of building something with my hands and then using my programming and problem-solving skills to make it move.”

Roberson, a senior, is majoring in aerospace engineering with a minor in computer science. As his winning robot demonstrates, he thrives at the intersection of both fields. He references the Mars Curiosity Rover as the type of project that inspires him; he even keeps a Lego model of Curiosity on his desk.

“You really have to trust that the hardware you’ve made is up to the task, but you also have to trust your software equally as much,” says Roberson, referring to the challenges of operating a rover from millions of miles away. “Is the robot going to continue to function after we’ve put it into space? Both of those things have to come together in such a perfect way to make this stuff work.”

Outside of formal classwork, Roberson has pursued multiple research opportunities at MIT that blend his academic interests. He’s worked on satellite situational awareness with the Space Systems Laboratory, tested drone flight in different environments with the Aerospace Controls Laboratory, and is currently working on zero-shot machine learning for anomaly detection in big datasets with the Mechatronics Research Laboratory.

“Whether that be space exploration or something else, all I can hope for is that I’m making an impact, and that I’m making a difference in people’s lives,” says Roberson. Photo: Jodi Hilton

Even while tackling these challenging technical problems head-on, Roberson is also actively thinking about the social impact of his work. He takes classes in the Program on Science, Technology, and Society, which has taught him not only how societal change throughout history has been driven by technological advancements, but also how to be a thoughtful engineer in his own career.

“Learning about the social implications of the technology you’re working on is really important,” says Roberson, acknowledging that his work in automation and machine learning needs to address these questions. “Sometimes, we get caught up in technology for technology’s sake. How can we take these same concepts and bring them to people to help in a tangible, physical way? How have we come together as a scientific community to really affect social change, and what can we do in the future to continue affecting that social change?”

Roberson is already working through what these questions mean for him personally. He’s been a member of the National Society of Black Engineers (NSBE) throughout his entire college experience, which includes serving on the executive board for two years. He’s helped to organize workshops focused on everything from interview preparation to financial literacy, as well as social events to build community among members.

“The mission of the organization is to increase the number of culturally responsible Black engineers that excel academically, succeed professionally, and positively impact the community,” says Roberson. “My goal with NSBE was to be able to provide a resource to help everybody get to where they wanted to be, to be the vehicle to really push people to be their best, and to provide the resources that people needed and wanted to advance themselves professionally.”

In fact, one of his most memorable MIT experiences is the first conference he attended as a member of NSBE.

“Being able to see all different these people from all of these different schools able to come together as a family and just talk to each other, it’s a very rewarding experience,” Roberson says. “It’s important to be able to surround yourself with people who have similar professional goals and share similar backgrounds and experiences with you. It’s definitely the proudest I’ve been of any club at MIT.”

Looking toward his own career, Roberson wants to find a way to work on fast-paced, cutting-edge technologies that move society forward in a positive way.

“Whether that be space exploration or something else, all I can hope for is that I’m making an impact, and that I’m making a difference in people’s lives,” says Roberson. “I think learning about space is learning about ourselves as well. The more you can learn about the stuff that’s out there, you can take those lessons to reflect on what’s down here as well.”