What is the best simulation tool for robotics?

What is the best simulation tool for robotics? This is a hard question to answer because many people (or their companies) specialize in one tool or another. Some simulators are better at one aspect of robotics than at others. When I’m asked to recommend the best simulation tool for robotics I have to find an expert and hope that they are current and across a wide range of simulation tools in order to give me the best advice, which was why I took particular note of the recent review paper from Australia’s CSIRO, “A Review of Physics Simulators for Robotics Applications” by Jack Collins, Shelvin Chand, Anthony Vanderkop, and David Howard, published in IEEE Access (Volume: 9).

“We have compiled a broad review of physics simulators for use within the major fields of robotics research. More specifically, we navigate through key sub-domains and discuss the features, benefits, applications and use-cases of the different simulators categorised by the respective research communities. Our review provides an extensive index of the leading physics simulators applicable to robotics researchers and aims to assist them in choosing the best simulator for their use case.”

Simulation underpins robotics because it’s cheaper, faster and more robust than real robots. While there are some guides that benchmark simulators against real world tasks there isn’t a comprehensive review. A more thorough review can address gaps and needs in research and research challenges for simulation. The authors focus on seven sub-domains: Mobile Ground Robotics; Manipulation; Medical Robotics; Marine Robotics; Aerial Robotics; Soft Robotics and Learning for Robotics.

I’m going to cut to the chase and provide a copy of the final comparison tables of each sub-domain but for anyone interested in utilizing these recommendations, then I recommend reading the rationale behind the rankings in the full review article. The authors also consider whether or not a simulator is actively supported. Handy to know! And the paper is also an excellent source of information about various historic and current robotics competitions.

Mobile Ground Robotics:

TABLE 1 Feature Comparison Between Popular Robotics Simulators

TABLE 2 Feature Comparison Between Popular Robotics Simulators Used for Mobile Ground Robotics

Manipulation:

TABLE 3 Feature Comparison for Popular Robotics Simulators Used for Manipulation

Medical Robotics:

TABLE 4 Feature Comparison of Popular Robotics Simulators Used for Medical Robotics

Marine Robotics:

TABLE 5 Feature Comparison of Popular Simulators Used for Marine Robotics

Aerial Robotics:

TABLE 6 Feature Comparison of Popular Simulators Used for Aerial Robotics

Soft Robotics:

TABLE 7 Feature Comparison of Popular Simulators Used for Soft Robotics

Learning for Robotics:

TABLE 8 Feature Comparison of Popular Simulators Used in Learning for Robotics

Conclusions:

As robotics makes more use of deep learning, simulators that can deal with data on the fly become necessary, and also a potential solution for simulation problems regarding points of contact or collisions. Rather than utilize multiple simulation methods to make a clearer abstraction of the real world in these boundary situations, the answer may be to insert neural networks trained to replicate the properties of difficult phenomena into the simulator. There is further discussion on differentiable simulation, levels of abstraction and the expansion of libraries, plug-ins, toolsets, benchmarking and algorithmic integration, all increasing both the utility and complexity of simulation for robotics.

As the field of simulation for robotics grows, so does the need for metrics that capture the accuracy of the real world representation. “Finally, we predict that we will see further research into estimating and modeling uncertainty of simulators.”

This may have been the first review article on simulation for robotics but hopefully not the last. There’s a clear need to study and measure the field. I found the sections on soft robotics and learning for robotics particularly interesting, as the paper discussed the difficulties of simulation in these fields. And please attribute any errors in this summary to my mistakes. Read the full review here: https://ieeexplore.ieee.org/document/9386154

How to Select the Right Motor for Your Robot

The Intersection of Telematics and Robotics

Don’t try to replace pets with robots; design robots to be more like service animals

Don’t try to replace pets with robots; design robots to be more like service animals

Air-powered computer memory helps soft robot control movements

A 3D-printed soft robotic hand that can play Nintendo

Amazon applies for patent on secondary delivery vehicle to carry packages from truck to doorstep

Neuro-evolutionary robotics: A gap between simulation and reality

Zebra To Acquire Fetch Robotics – Our Analysis

Automation Lends Humans a Hand in High-mix Low-volume Manufacturing

Sniffy Bug: a fully autonomous swarm of gas-seeking nano quadcopters in cluttered environments

Tiny drones are ideal candidates for fully autonomous jobs that are too dangerous or time-consuming for humans. A commonly shared dream by engineers and fire & rescue services, would be to have swarms of such drones help in search-and-rescue scenarios [1], for instance to localize gas leaks without endangering human lives. Tiny drones are ideal for such tasks, since they are small enough to navigate in narrow spaces, safe, agile, and very inexpensive. However, their small footprint also makes the design of an autonomous swarm extremely challenging, both from a software and hardware perspective.

From a software perspective, it is really challenging to come up with an algorithm capable of autonomous and collaborative navigation within such tight resource constraints. State-of-the-art solutions like Simultaneous Localization and Mapping (SLAM) require too much memory and processing power. A promising line of work is to use bug algorithms [2], which can be implemented as computationally efficient finite state machines (FSMs), and can navigate around obstacles without requiring a map.

A downside of using FSMs is that the resulting behavior can be very sensitive to their hyperparameters, and therefore may not generalize outside of the tested environments. This is especially true for the problem of gas source localization (GSL), as wind conditions and obstacle configurations drastically change the problem. In this article, we show how we tackled the complex problem of swarm GSL in cluttered environments by using a simple bug algorithm with evolved parameters, and then tested it onboard a fully autonomous swarm of tiny drones. We will focus on the problems that were encountered along the way, and the design choices we made as a result. At the end of this post, we will also add a short discussion about the future of tiny drones.

Why gas source localization?

Overall we are interested in finding novel ways to enable autonomy on constrained devices, like tiny drones. Two years ago, we showed that a swarm of tiny drones was able to explore unknown, cluttered environments and come back to the base station. Since then, we have been working on an even more complex task: using such a swarm for Gas Source Localization (GSL).

There has been a lot of research focussing on autonomous GSL in robotics, since it is an important but very hard problem [3]. The difficulty of the task comes from the complexity of how odor can spread in an environment. In an empty room without wind, a gas will slowly diffuse from the source. This allows a robot to find the source by simply moving in the direction that makes the gas concentration go up, just like small bacteria like E. Coli do to find nutrients. However, if the environment becomes larger with many obstacles and walls, and wind comes into play, the spreading of gas is much less regular. Large parts of the environment may have no gas or wind at all, while at the same time there may be pockets of gas away from the source. Moreover, chemical sensors for robots are much less capable than the smelling organs of animals. Available chemical sensors for robots are typically less sensitive, noisier, and much slower.

Due to these difficulties, most work in the GSL field has focused on a single robot that has to find a gas source in environments that are relatively small and without obstacles. Relatively recently, there have been studies in which groups of robots solve this task in a collaborative fashion, for example with Particle Swarm Optimization (PSO). PSO was first invented as a way to model the social behavior of foraging birds, in which the birds communicate with each other how good the food at their location is. The birds then follow a direction that is determined both by their own observations and the best observed location of the swarm. PSO turned out to be a great optimization algorithm for many different real-world problems. Thanks to the different particles in the swarm, it can escape local optima. In the case of GSL, PSO allows a swarm of robots to collaboratively seek a gas source, while ignoring pockets of gas away from the gas source. Until now this concept has been shown in simulation [4] and on large outdoor drones equipped with LiDAR and GPS [5], but never before on tiny drones in complex, GPS-denied, indoor environments.

Required Infrastructure

In our project, we introduce a new bug algorithm, Sniffy Bug, which uses PSO for gas source localization. In order to tune the FSM of Sniffy Bug, we used an evolutionary algorithm. This type of algorithm mimics the survival of the fittest in natural evolution, but now with “fitness” defined as being able to localize a gas source as efficiently as possible. The evolution starts out with random controllers for the swarm of robots, evaluates them in simulation, and selects the fittest controllers for reproduction. Over the generations, the controllers become increasingly good at the task. After evolution, the best controller is transferred to the real robots in the swarm.

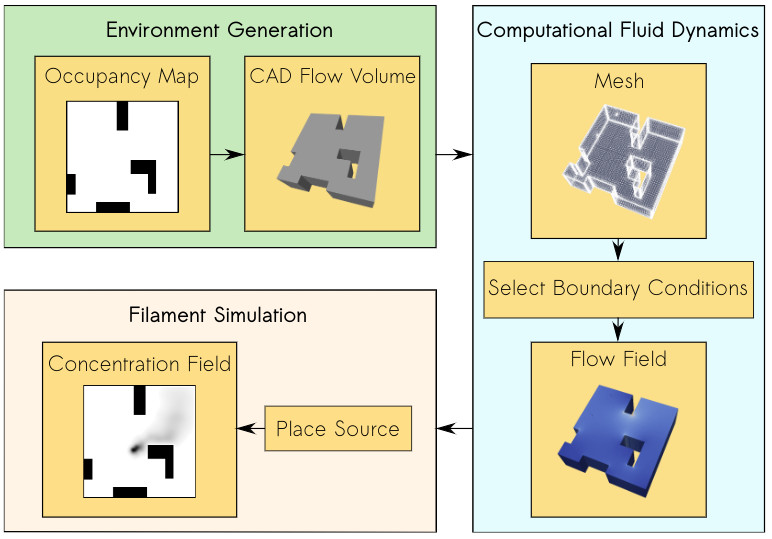

Of course, for this evolution to work well, we need a good simulation of how gas spreads in a complex, indoor environment. However, early in the project, we realized that this would be a challenge, as no end-to-end gas modeling pipeline existed yet. It is important to have an easy-to-use pipeline that does not require any aerodynamics domain knowledge, such that as many researchers as possible can generate environments to test their algorithms. It would also make it easier to compare contributions and to better understand in which conditions certain algorithms work or don’t work. The GADEN ROS package [6] is a great open source tool for modelling gas distribution when you have an environment and flow field, but for our objective, we needed a fully automated tool that could generate a great variety of random environments on-demand with just a few parameters. Below is an overview of our simulation pipeline: AutoGDM.

First, we use a procedural environment generator proposed in [7] to generate random walls and obstacles inside of the environment. Then, gas dispersion modeling (GDM) is done by first modeling a 3D flow field, i.e., the direction and magnitude of wind velocity at every point in space. Next, a gas source location is chosen. Then, at the source, gas filaments are released in the flow field and randomly expanded over time. This results in a time-varying gas concentration field. The 3D flow field is heavily impacted by something referred to as “boundary conditions”: the conditions at the walls in the environment that we feed into the computational fluid dynamics (CFD) solver. In our case, this means for some walls we tell the CFD to force a wind velocity of 0 m/s, while for others we may tell it to model an inlet or an outlet of air, like an open window. Determining the boundary conditions is done automatically by AutoGDM.

Since a hard requirement for us was that AutoGDM needed to be free to use, we chose to use the open-source CFD tool OpenFOAM. It’s used for cutting-edge aerodynamics research, and also the tool suggested by the authors of GADEN. Without AutoGDM, using OpenFOAM isn’t trivial, as a large number of parameters that require field expertise need to be selected, resulting in a complicated process. GADEN was used to take the environment definition (CAD files) and the flow field from OpenFOAM to generate the gas concentration field over time.

After we built this pipeline, we still needed a robot simulator. Since we weren’t planning on using a camera, our main requirement was for the simulator to be efficient (preferably in 2D) so that evolutions would take relatively little time. We decided to use Swarmulator [8], a computationally efficient C++ robot simulator designed for swarming and we plugged in our gas data.

Algorithm Design

Roughly speaking, we considered two categories of algorithms for controlling the drones: 1) a neural network, and 2) an FSM that included PSO, with evolved parameters. We first evolved neural networks in simulation. One of the first experiments is shown below.

While it worked pretty well in simple environments with few obstacles, it seemed challenging to make this work in real life with complex obstacles and multiple agents that need to collaborate. Given the time constraints of the project, we opted for evolving the FSM. This also facilitated crossing the reality gap (i.e., the difference between simulation and real-world behaviour), as the simulated evolution could build on basic behaviors that we developed and validated on the real platform, including obstacle avoidance with four tiny laser rangers, while communicating with and avoiding other drones. An additional advantage of PSO with respect to the reality gap is that it only needs gas concentration and no gradient of the gas concentration or wind direction (which many algorithms in literature use). On a real robot at this scale, estimating the gas concentration gradient or the direction of a light breeze is hard if not impossible.

Hardware

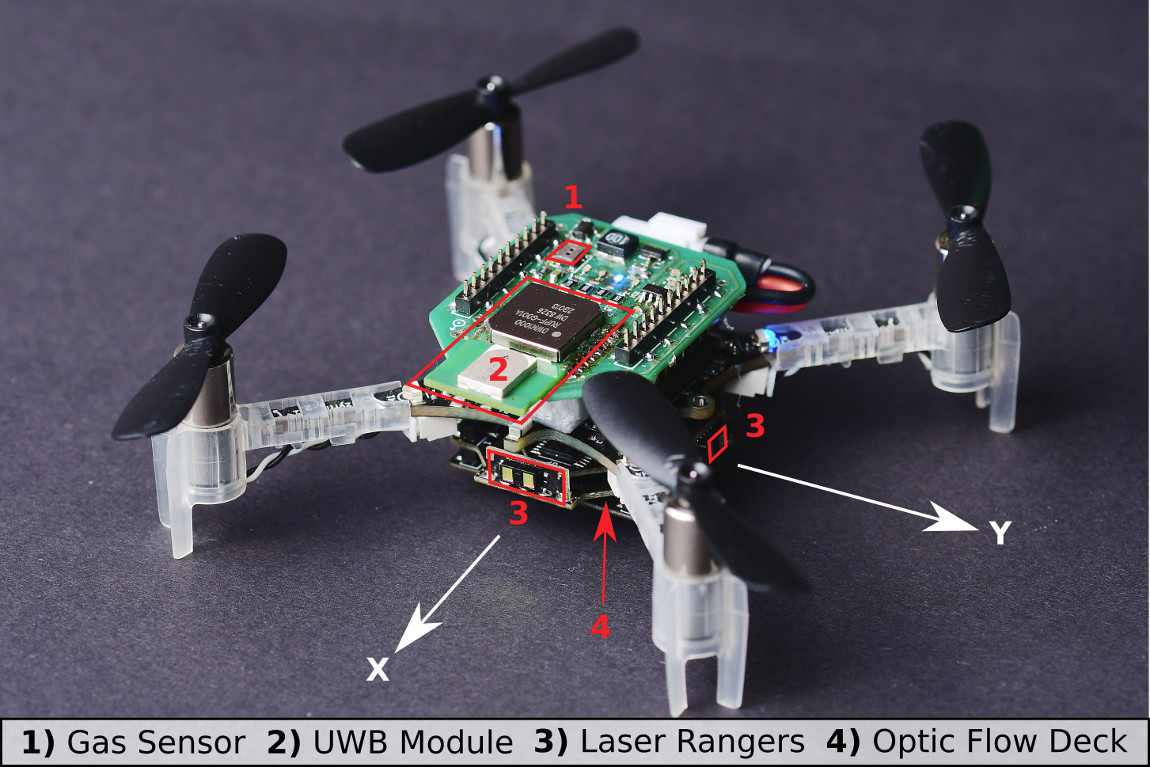

We deploy a 37.5g Bitcraze CrazyFlie nano drone that is capable of avoiding obstacles, executing velocity commands, sensing gas, and estimating the other agent’s position in its own frame. For navigation we added a down-facing optic flow sensor and four laser rangers, whereas for gas sensing we used a TGS8100 gas sensor that was used on a CrazyFlie before in previous work [9]. The sensor is lightweight and inexpensive, but accurately estimating gas concentrations can be difficult because of its size. It tends to drift and needs time to recover after a spike in concentration is observed. Another thing we noticed is that it is possible to break them, a crash can definitely destroy the sensor.

To estimate the relative position between agents, we use a Decawave Ultra-Wideband (UWB) module and communicate states, as proposed in [10]. We also use the UWB module to communicate gas information between agents and collaboratively seek the source. The complete configuration is visible below.

Evaluation in Simulation

After we optimized the parameters of our model using Swarmulator and AutoGDM, and of course trying many different versions of our algorithm, we ended up with the final Sniffy Bug algorithm. Below is a video that shows evolved Sniffy Bug evaluated in six different environments.

The red dots are an agent’s personal target waypoint, whereas the yellow dot is the best-known position for the swarm. Simulation shows that Sniffy Bug is effective at locating the gas source in randomly generated environments. The drones successfully collaborate by means of PSO.

Real Flight Testing

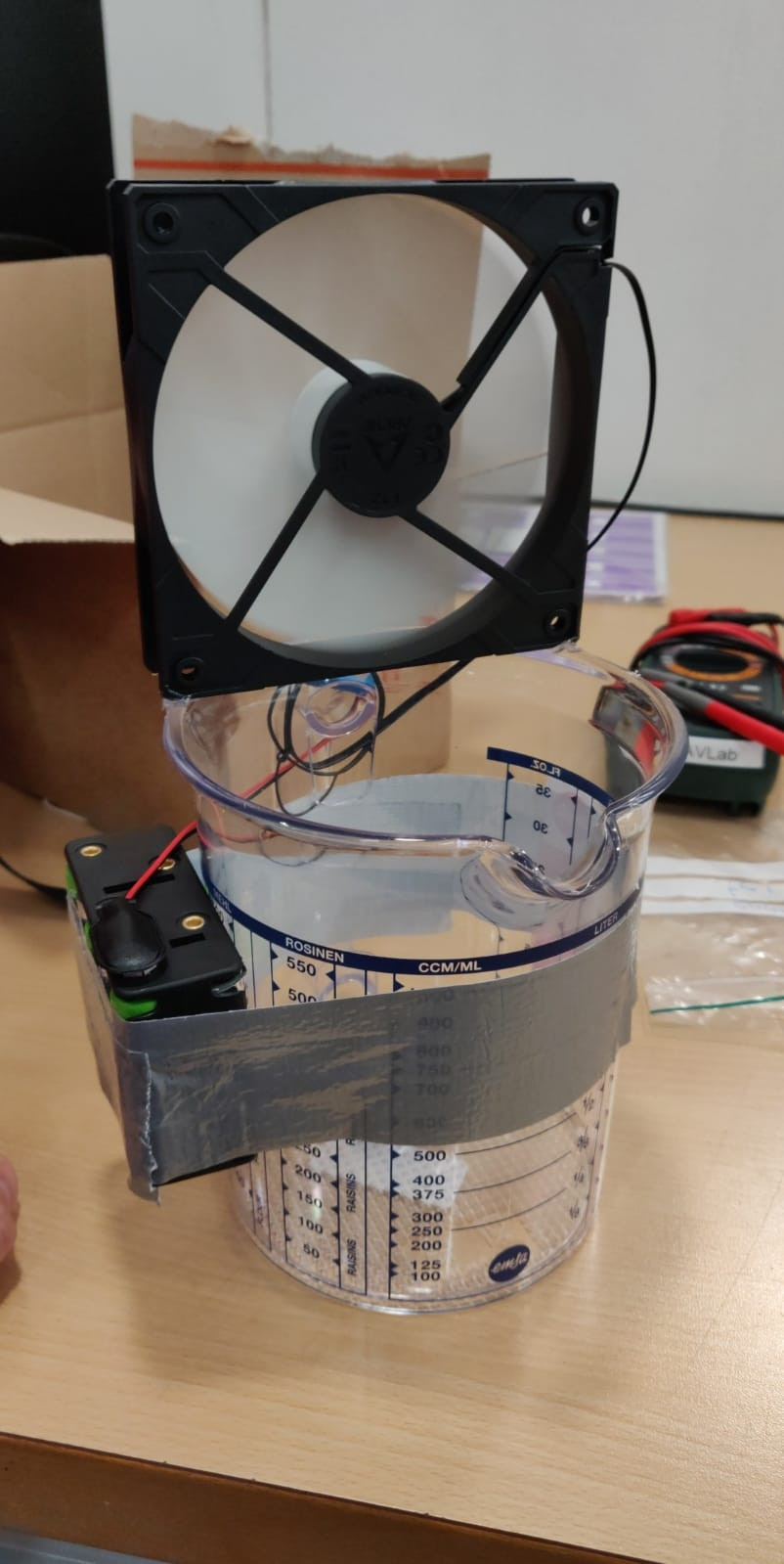

After observing Sniffy Bug in simulation we were optimistic, but unsure about performance in real life. First, inspired by previous works, we dispersed alcohol through the air by placing liquid alcohol into a can which was then dispersed using a computer fan.

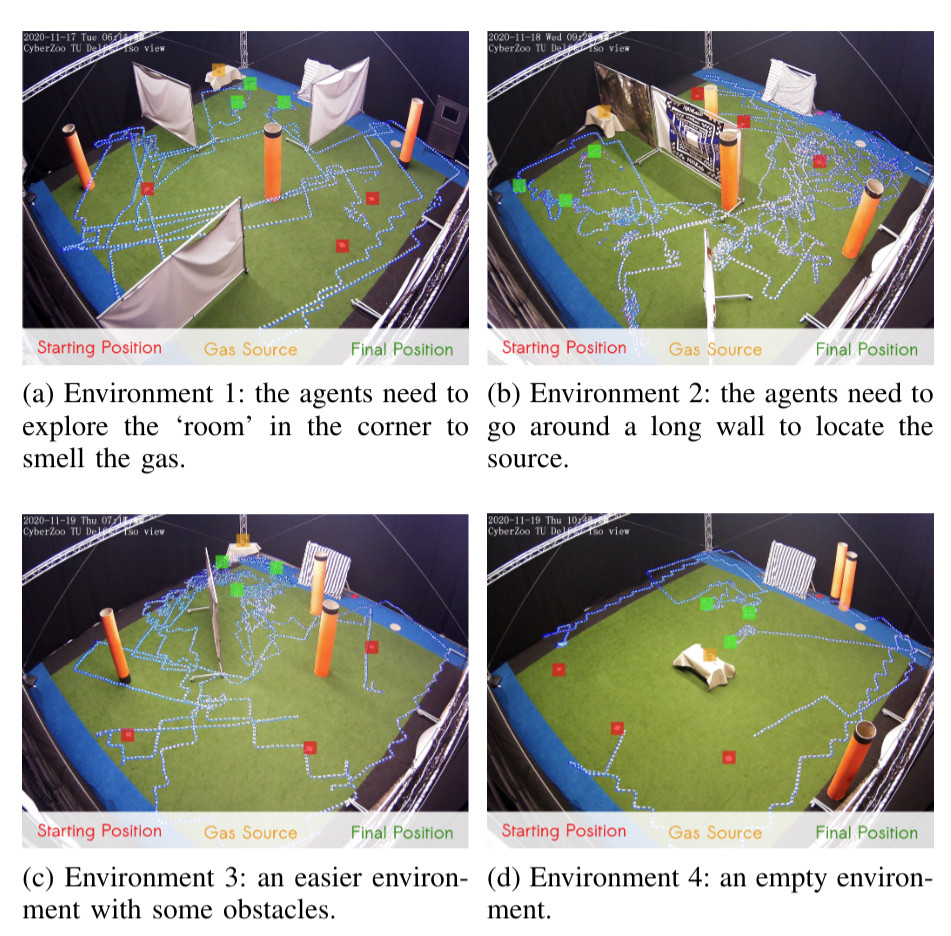

We tested Sniffy Bug in our flight arena of size 10 x 10 meters with large obstacles that were shaped like walls and orange poles. The image below shows four flight tests of Sniffy Bug in cluttered environments, flying fully autonomously, i.e., without the help from any external infrastructure.

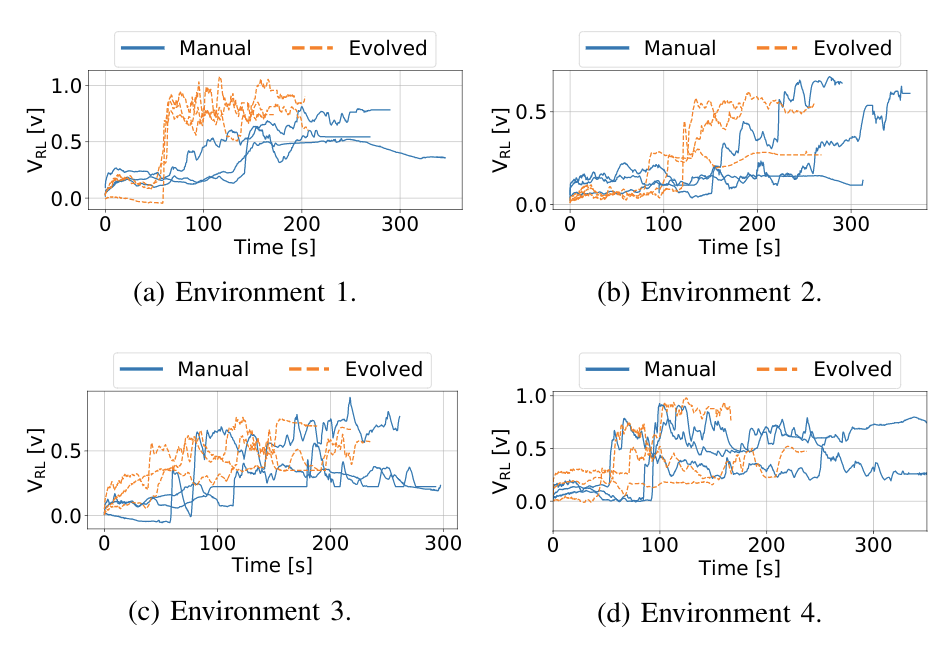

In the total of 24 runs we executed, we compared Sniffy Bug with manually selected and evolved parameters. The figure below shows that the evolved parameters are more efficient in locating the source as compared to the manual parameters.

This does not only show that our system can successfully locate a gas source in challenging environments, but it also demonstrates the usefulness of the simulation pipeline. The parameters that were learned in simulation yield a high-performance model, validating the environment generation, randomization, and gas modeling parts of our pipeline.

Conclusion and Discussion

With this work, we believe we have made an important step towards swarms of gas-seeking drones. The proposed solution has been shown to work in real flight tests with obstacles, and without any external systems to help in localization or communication. We believe this methodology can be extended to larger environments or even to 3 dimensions, since PSO is a robust, multi-dimensional heuristic search method. Moreover, we hope that AutoGDM will help the community to better compare gas seeking algorithms, and to more easily learn parameters or models in simulation, and deploy them in the real world.

To improve Sniffy Bug’s performance, adding more laser rangers will definitely help. When working with only four laser rangers you realize how little information they actually provide. If one of the rangers senses a low value, it is unclear if a slim pole or a massive wall is detected, adding inefficiency to the algorithm. Adding more laser rangers or using other sensor modalities like vision will help to avoid also more complex obstacles than walls and poles in a reliable manner.

Another interesting discussion can be held on the hardware required for real deployment. When working with 40 grams of maximum take-off weight, the sensors and actuators that can be selected are limited. For example, the low-power and lightweight flow deck works great but fails in low-light scenarios or with smoke. Future work exploring novel sensors for highly constrained nano robots could really help increase the Technological Readiness Level (TRL) of these systems.

Finally, this has been a really fun project to work on for us and we can’t wait to hear your thoughts on Sniffy Bug!

References

[8] https://github.com/coppolam/swarmulator

Links

ArXiv: https://arxiv.org/abs/2107.05490

Video: https://www.youtube.com/watch?v=hj_SBSpK5qg

Code: https://github.com/tudelft/sniffy-bug

Please reach out if you have any questions or ideas, you can reach us at: b.p.duisterhof@gmail.com or g.c.h.e.decroon@tudelft.nl